eaglesdare wrote: my foamie isapprox 500lb total, with mattress. that includes the frame, which is 265lbs.

1.The frame is over 1/2 the weight. Really need to make the frame lighter.

Been reading about moncoque and unibody designs.

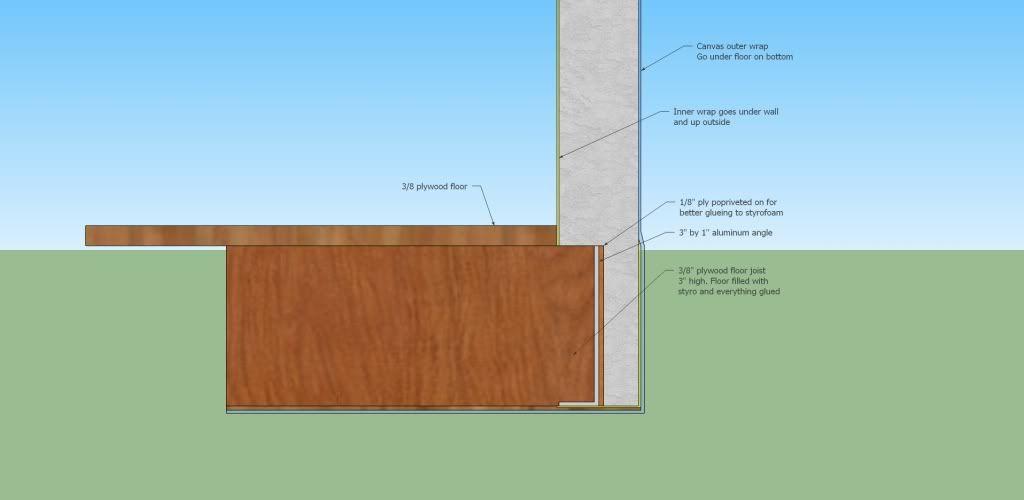

For us the walls need to replace the frame, they are actually just really tall beams, and have the floor hang off the walls. Easy to do if your walls are between the wheels.

Working on how to do it when your going maximum width and have to go over the wheels with the body.

2.Also if you put foam in the floor it becomes a torsion box and you do not need heavy plywood or anywhere near as much for 'joists'/framing.

3. Instead of using wood or metal joists in the floor I am wondering about wrapping the edge of the Styrofoam with canvas and glue/paint. Say use 2x8 Styrofoam, wrap the edge with canvas (do not need to do whole surface). So every 2' you have a double layer of canvas. then put a 1x2 or whatever thickness your floor is around the perimeter and plywood on top and bottom. All glued of course.