new hybrid fomie

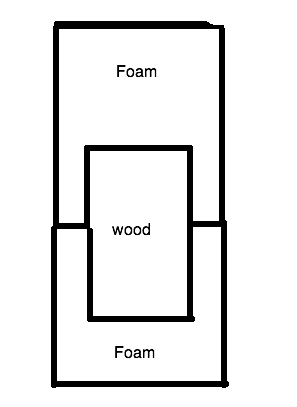

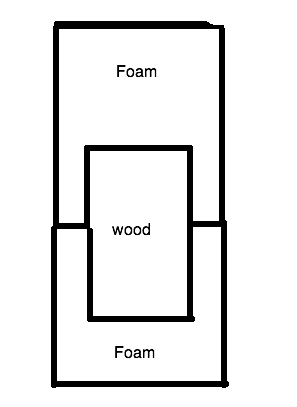

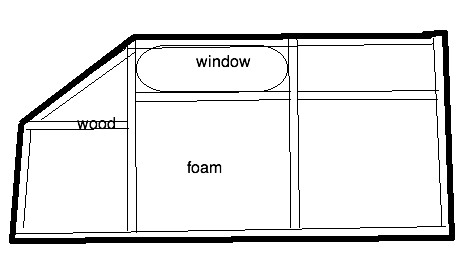

So I am starting to think about the foamie that I will make this fall. I don't have a layout in mind yet, looking to make it a motorcycle hauler as well. But and just thinking about construction methods, and this is what I was thinking for the side walls. I want to incorporate some minimal wood framing to and use the foam to encapsulate the wood for strength. Was thinking of using 1x2 or 1x3's for the framing and notch out the 2" foam to fit into the framing like:

I was also thinking that using this method I could get by with just one application of fiberglass epoxy and maybe additional small strips on the seams instead of using two applications like most use on the walls to save a little money on glassing the outside. Any input is welcomed!!

I was also thinking that using this method I could get by with just one application of fiberglass epoxy and maybe additional small strips on the seams instead of using two applications like most use on the walls to save a little money on glassing the outside. Any input is welcomed!!

You could do a dowel and plate style hard point for lighter things (after the fact) , but for shelves, bed frames, etc , you might need More bracing and that should be considered prior to the build ...

You could do a dowel and plate style hard point for lighter things (after the fact) , but for shelves, bed frames, etc , you might need More bracing and that should be considered prior to the build ...