I realize that this ^ is a slightly older posting, but I have some good hands on experience working with 1-1/2 thk foam board and 1/4 inch ply inner skins (actually 5mm or 3/16 inch). My main reasoning was that I wanted the traditional feel of a wooden interior, and didn’t want to try and install PMF on the inside after building the box, but there are great structural benefits to paneling the foam walls, too.

IMO this is a great and sturdy technique, and would easily support a bunk bed without wall studs or dedicated stanchions in a TD sized camper, however I would definitely add some substantial blocking.

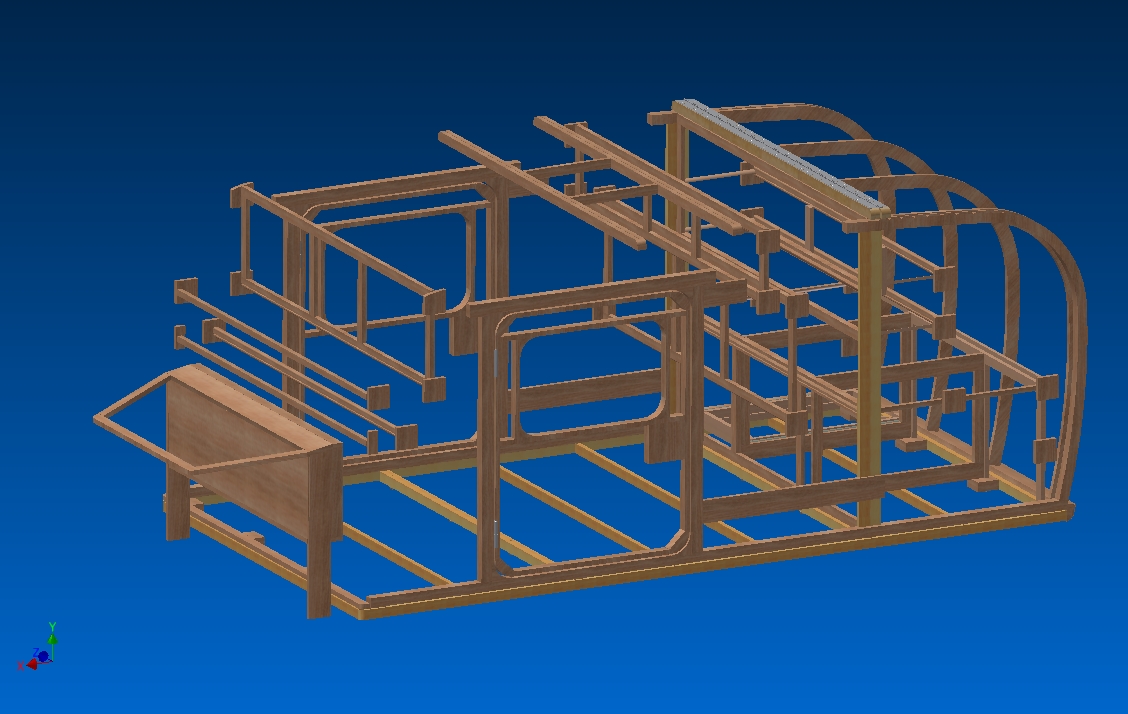

Be aware that adding blocking to a foamie can be a proverbial "rabbit hole". I present to you for your consideration TPCE dinosaur puzzle (a 3D computer model image of my hybrid camper design with all of the foam and interior panels "turned off".

You can see the mostly square 1 inch nominally thick blocks (3/4 x 3-1/2 x 3-1/2 actual size) of mostly pine (some poplar) at each of the cabinet rail and galley counter ends. Larger pieces were used for the fender mounts, side table cleats (not shown), and porch lights (on the lights just because they were so close to the corner of the door frame anyway). Figuring out what was needed for everything ahead of time… and there is a lot of stuff to think about… took quite a while. Light switches, coat hooks, interior lighting, exterior lighting, etc., etc…. the cabinet supports were the easiest because they were pre planned. I mostly used pocket screws in the “backs” of the cabinet frames, screwed through the ply and into the hidden blocking. For some other stuff (axe and shovel mounts, and fenders) I am/will be using threaded inserts or T-nuts imbedded into the blocking.

The inside stuff got blocking on the inside of the foam, the outside stuff was on the outside. The only blocking that goes all the way through (AFAIRCATM) was at the door latch.

At several points in the process of routing the pockets into the foam, gluing the blocks in a few at a time, trimming and fairing the (relatively) hard glue without making a shallow in the adjacent soft foam, and wondering if I was forgetting any potential future needs, I wondered if the weight savings was worth all of the extra effort to go foam and to build it this way. I’m sure my camper would have been completed years ago if I had built more traditionally. I’m not slighting foamies here, but the hybrid methods I chose (and my particular attention to details) really added build time to the process. Everything sounds easy to do, and you don’t expect it to take a lot of time, but it adds up.

Mind you that none of this has gone bouncing down the road under load yet, but you can tell how strong it all is once it all starts coming together.

I would think that you could build a much lighter bed frame, perhaps 1x4 on vertical edge with a 3/8 ply deck dadoed in, and then just screw through the head and toe boards into your wall blocking. What you show above looks like 2x framing lumber and heavier ply, which, IMO, is heavy, defeating one of the big advantages to unitized foamie construction. No offense intended.

( did you weigh it with mattresses … ? ) I’d like something like that for my house …

( did you weigh it with mattresses … ? ) I’d like something like that for my house …