General guidelines???

Do I want to always glue foam to foam, or can I glue covered foam to foam or covered foam?

Do I want both sides covered before I Glue walls to floor, to roof, etc?

If I plan to use the foam cut from an opening to make the door, do I want it all covered before I cut, then add covering, or should I always cut out then cover?

Come to think of it, should I wash that drop cloth canvas before gluing, so any shrinkage will have already happened, or will gluing fresh canvas and having a little shrinkage add to the strength?

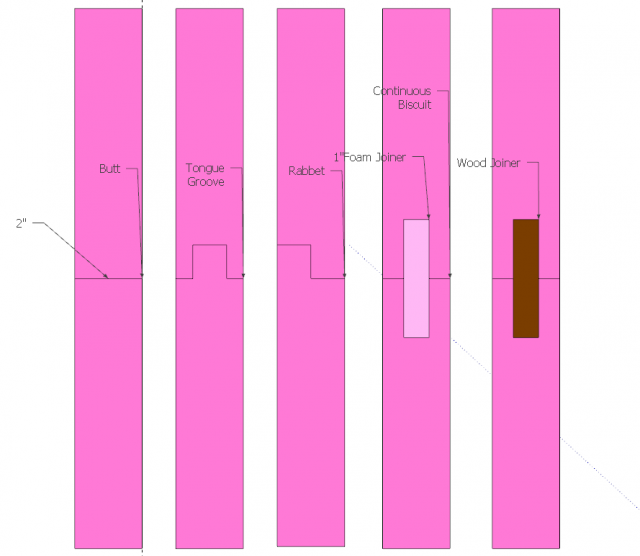

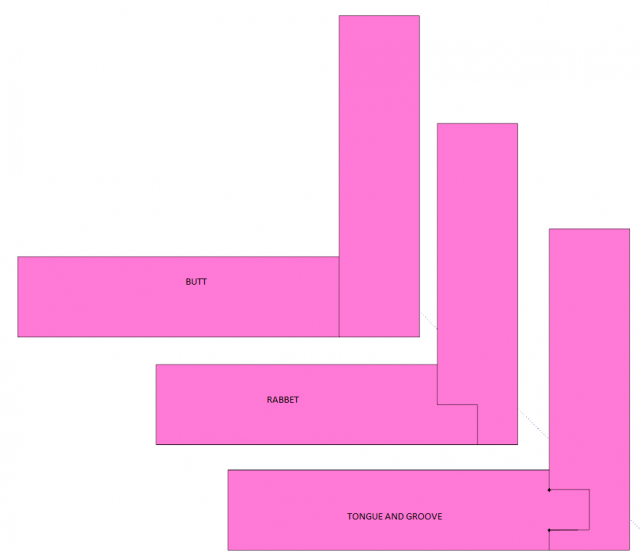

I’m thinking all 2” foam, a 5x10x4 shell, two doors and a rear hatch. I have discovered that manufactured doors are EXPENSIVE.

Might build in a shelf, partition or ceiling arch, to add stiffness.

)

)