Page 1 of 2

Framing considerations for strength and weight...

Posted:

Mon Aug 30, 2021 10:46 amby dbhosttexas

So as y'all know by now, one of my biggest concerns, and reasons for wanting a foamie build, aside from the obvious insulation value, is the weight issue. I know I can build framing using aluminum, but I am not super skilled or equipped for welding aluminum, so I would be limited to making corner braces, and brazing the joints / riveting the braces in place, and of course brazing iwth Alumiweld. I am nnot super certain of the strength of this, or even how strong this SHOULD be...

I am giving consideration to wood framing, but that brings concerns of weight, and rot resistance. I figure I would have to use plywood for dimensional stability, but again, how to keep it from rotting, and how to design it for maximum strength with minimum weight. Most likely using a variety of joinery, including mitered half laps, locking rabbets, and if absolutely necessary for strength sake, blind dovetails. I do have the skill and equipment to manage those...

My thought process is this... for right or wrong...

Skeletal structure of 3/4" cabinet grade ply, each panel from a single sheet, ripped to height, with maybe 16" horizontal spacing between sections, with 1.5" wide brace panels, L braced at bottoms, so we are at 1.5" thick. fit outer foam fill, fit inner foam fill, bond and install inner, bond and isntall outer, skin.

Load bearing segments such as the supports for door, AC, awning, and Fantastic Fan should be framed in with 2x2.

Just wondering how this would impact the weight of the camper. Again the issue here is I am limited to a farily severe extend by the capacity of the truck itself... Trying to work with what I have...

Re: Framing considerations for strength and weight...

Posted:

Mon Aug 30, 2021 1:58 pmby Pmullen503

A foamy covered in canvas and glue doesn't need any framing to hold together. Now windows, hatches and doors do need something to attach hinges to besides the foam. You can either inlay pieces of plywood or use wood framing for fasteners. For something like an ac unit, especially one that doesn't get removed for travel, I would use wood framing to carry the weight down to the floor. Something like 1 1/2"x2" studs (for 2" foam).

My foamy (8 years old now) has 1 1/2"x 2" solid wood glued onto the edges of the foam for the hatches and doors (wrapped in PMF) and plywood Wiley windows inlaid into the foam on the outside (1/4"). The sides of the windows glued to the foam. It's held up fine.

As far as rot is concerned, make sure there is no place where water can collect and sit for a period of time. Pay attention to drainage and the use of drip edges.

Re: Framing considerations for strength and weight...

Posted:

Mon Aug 30, 2021 4:05 pmby Tomterrific

I made my camper as quick as posible. I used thin and weak 5mm Revolution ply. It is strong because the corners are strong and the sides have battens. It is not heavy.

I have thought about the foamy concept and really like all the experimentation from the guinea pigs. It is a successful way to build a tiny camper! My outsider take is the corner between the wall and ceiling and the wall and floor is critical for strength. I'd check with the successful foamy builds to see how they did this. I read where someone used chop sticks as nails to attach the foam boards to each other. I loved that idea. I'd smear some glue on the sticks as they were 'nailed'.

Tt

Re: Framing considerations for strength and weight...

Posted:

Mon Aug 30, 2021 5:16 pmby ghcoe

No need for reinforcement as long as you wrap the canvas properly.

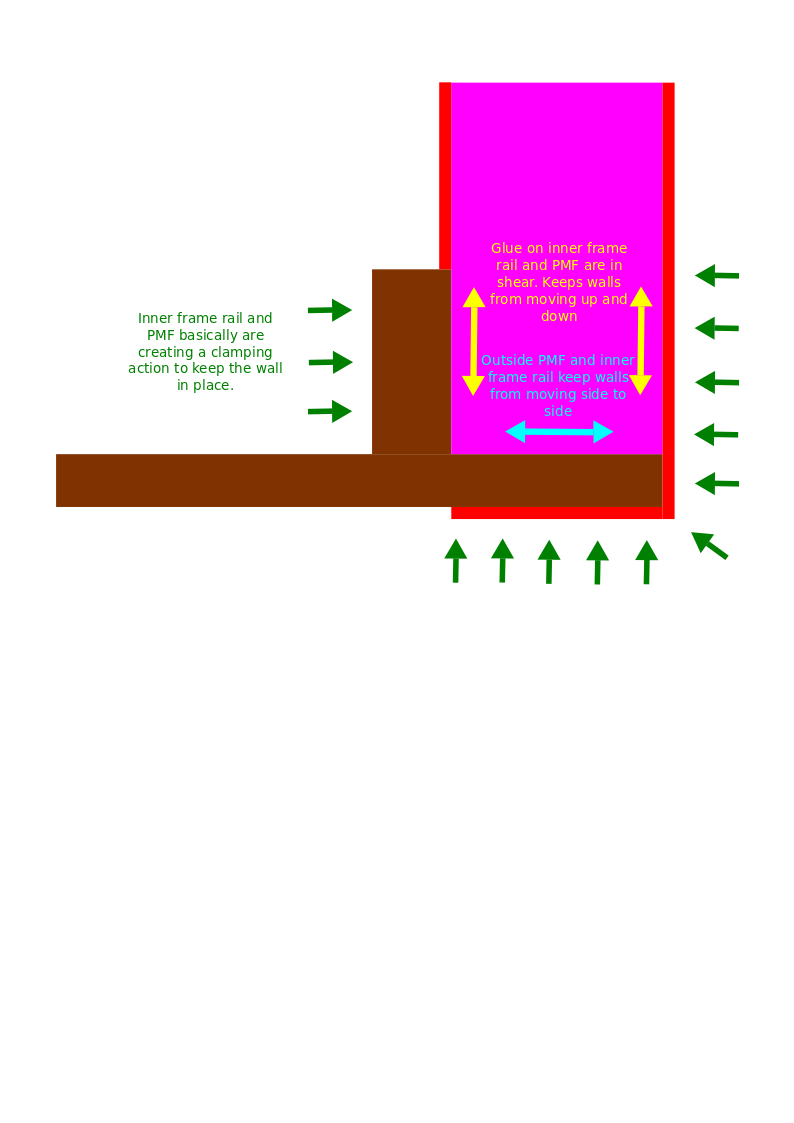

I use what I call inner frame rails to help attach the walls to the floor. These frame rails keep the walls from being pushed in. The canvas keeps the walls from being pushed out or up. The rails also help keep the floor from flexing next to the wall on the interior. This flexing can cause delamination of the floor to wall glue up.

- inner frame rails

- Inner Frame Rail and PMF explanined.png (36.23 KiB) Viewed 1554 times

If you are going over 4' wide I would consider some sort of extra roof support. I usually use 2"x2" embedded into the walls that the roof will rest on once installed. Easy to do.

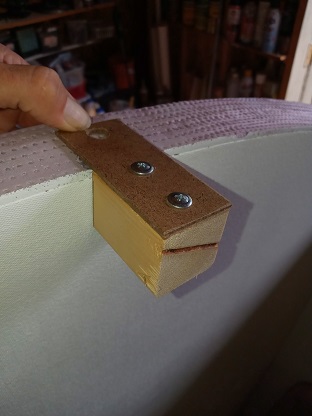

Make a simple template to know where to cut.

- Template

- 20200925_162318 s.jpg (35.53 KiB) Viewed 1554 times

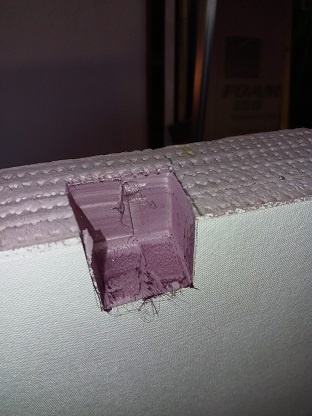

Cut back into the wall far enough so the 2"x2" has enough support from the walls.

- Cutout

- 20200925_164611 s.jpg (46.65 KiB) Viewed 1554 times

Re: Framing considerations for strength and weight...

Posted:

Mon Aug 30, 2021 5:22 pmby ghcoe

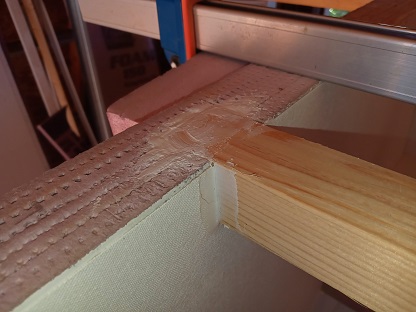

Then I use Dap Caulking to embed the 2"x2" into the wall.

- Embed roof support

- 20200927_154244 s.jpg (46.78 KiB) Viewed 1551 times

Best shot I have of the support installed.

- Finished

- 20210610_135716 s.jpg (394.17 KiB) Viewed 1551 times

Re: Framing considerations for strength and weight...

Posted:

Mon Aug 30, 2021 8:00 pmby pchast

Neat work. How did you cut the pocket there?

Re: Framing considerations for strength and weight...

Posted:

Mon Aug 30, 2021 10:03 pmby ghcoe

pchast wrote:Neat work. How did you cut the pocket there?

I used a box cutter to cut the canvas first and then I used a trigger style soldering gun with a modified tip to cut out the foam.

Re: Framing considerations for strength and weight...

Posted:

Tue Aug 31, 2021 9:01 amby twisted lines

ghcoe wrote:pchast wrote:Neat work. How did you cut the pocket there?

I used a box cutter to cut the canvas first and then I used a trigger style soldering gun with a modified tip to cut out the foam.

Thanks again George!

I found a soldering gun but, have been hunting for nut's

both sizes

#2

Re: Framing considerations for strength and weight...

Posted:

Tue Aug 31, 2021 3:17 pmby printer

I used 14 gauge wire as a soldering gun tip for years. Started using 12 gauge lately but #14 should be good enough for the foam. Hard to do without the proper nuts though.

Re: Framing considerations for strength and weight...

Posted:

Wed Sep 01, 2021 5:37 pmby dbhosttexas

My camper build will be truck based, and I keep going between what can best be described as an extended truck topper type camper, think hi top contractors cap that is wide enough for an east / west king size bed, and extended over the tailgate in the open position, OR a flatbed camper build similar to RJ Howells.

IF I can do this with a camper shell build, I would need the support for the shell itself, bed, AC and door in the back wall, windows in the sides, roof vent, and of course, awning.

I am NOT adverse to doing hand laid fiberglass over foam but that puts me at using epoxy resin to keep from eating up the foam. I know that would help with strength, but ram the costs up more than I want...

The overall idea here is not to be fully self contained within the truck, but rather to be based in and around the truck. I.E. truck is hauling machine with protected kitchen outside, AND privy tent on other side of truck most likely...

The reasons behind a foamie build are actually kind of simple.

#1. My wife wants a king size bed. Most commercial RVs don't offer them.

#2. We have a half ton truck, and want to keep it instead of dropping $50K + on a heavy duty pickup.

#3. I want a camper we can take places most towables are not able to safely go. Beaches, Logging roads, etc... Not anything radical like the Rubicon trail... but also stuff that I would be unwilling ot drag a trailer down, unless that trailer is built for offroad purposes. Most of them are nothing more than gear haulers...

Re: Framing considerations for strength and weight...

Posted:

Wed Sep 01, 2021 10:58 pmby twisted lines

Instead of a king would two twin's or tall twin's pass

Use them like cushions as George has here in the day or travel, so you don't toss thing's on the bed.

I am a big gimpy guy that was board and started drawing a offroad light weight foamy today,

For my Mothers tracker

Because I can't find a TV.

Clutch for the sciatica,

Off Road because I don't trust the thing over 40

Can't wait for the Other two Radiculopathy's, Off roading with me driving

I Do Have a good event planed one way at least for this pair

Two now If I make it through the first one, I will sell it at the second one

Re: Framing considerations for strength and weight...

Posted:

Thu Sep 02, 2021 7:03 pmby ghcoe

dbhosttexas wrote:#3. I want a camper we can take places most towables are not able to safely go. Beaches, Logging roads, etc... Not anything radical like the Rubicon trail... but also stuff that I would be unwilling ot drag a trailer down, unless that trailer is built for offroad purposes. Most of them are nothing more than gear haulers...

My trailer is built on a Harbor Freight frame. I added 13" wheels/tires and a 2"x2" square tube down the center. Been beating on it in the backcountry for 3 years now. I did finally brake a spring this spring so I converted the springs to a soft ride suspension that a person makes out of Oregon. It is ready for many more off road miles. I often though I would have to install bigger wheels than the 13", but so far it has done everything I have asked it to without any issues.

The thing about a trailer is you can leave it at camp as you go get groceries, or go out on the trail for the day.

You can check out my YouTube channel. If I am going on trips that are overnight the trailer is with me.

https://www.youtube.com/channel/UCYuRx2 ... ztg/videos

Re: Framing considerations for strength and weight...

Posted:

Mon Sep 06, 2021 8:16 amby dbhosttexas

ghcoe wrote:dbhosttexas wrote:#3. I want a camper we can take places most towables are not able to safely go. Beaches, Logging roads, etc... Not anything radical like the Rubicon trail... but also stuff that I would be unwilling ot drag a trailer down, unless that trailer is built for offroad purposes. Most of them are nothing more than gear haulers...

My trailer is built on a Harbor Freight frame. I added 13" wheels/tires and a 2"x2" square tube down the center. Been beating on it in the backcountry for 3 years now. I did finally brake a spring this spring so I converted the springs to a soft ride suspension that a person makes out of Oregon. It is ready for many more off road miles. I often though I would have to install bigger wheels than the 13", but so far it has done everything I have asked it to without any issues.

The thing about a trailer is you can leave it at camp as you go get groceries, or go out on the trail for the day.

You can check out my YouTube channel. If I am going on trips that are overnight the trailer is with me.

https://www.youtube.com/channel/UCYuRx2 ... ztg/videos

Mind you, I have a Pop Up that can be rebuilt pretty easily, which I am working on. But my plan was to fix it up, get it trip ready and sell it. There are plenty of folks that lift PUs, Not so sure how good of an idea that is.

Re: Framing considerations for strength and weight...

Posted:

Mon Sep 06, 2021 11:05 amby dbhosttexas

twisted lines wrote:Instead of a king would two twin's or tall twin's pass

Use them like cushions as George has here in the day or travel, so you don't toss thing's on the bed.

I am a big gimpy guy that was board and started drawing a offroad light weight foamy today,

For my Mothers tracker

Because I can't find a TV.

Clutch for the sciatica,

Off Road because I don't trust the thing over 40

Can't wait for the Other two Radiculopathy's, Off roading with me driving

I Do Have a good event planed one way at least for this pair

Two now If I make it through the first one, I will sell it at the second one

If you've been following my posts. I am tenting in the mean time of building the camper. I am using a pair of couble high heavy duty twins teamed together with a king size fitted sheet with extra deep pockets.

It's actually quite comfy. And yes, I have considered a pair of twin mattresses so that I don't have to chop the ends off... Probably not a bad idea still as Tri folds can actually be quite comfortable. And typically are 6" thick so easier to deal with height wise...

Re: Framing considerations for strength and weight...

Posted:

Mon Sep 06, 2021 1:42 pmby twisted lines

I have seen a few

I am a big old gimpy guy and love my king; but know I can't take it with me.

I have yet to pick my Queen (BED)

both sizes

both sizes

#2

#2