I've always had a different approach to building a hatch. Instead of building heavy to prevent "Spring Back", Use materials that Don't "Spring Back"

I use FRP and Aluminum.

I build 2 outside rails, 1" thick (by using 2 pieces of 1/2") And cross spars. Then I cover the outside with FRP, good side in extending 1 1/2 past the rails on both sides.

FRP does not "Spring Back" and is strong enough when bowed around the hatch to not flex...as well as being stable enough to Triangulate the hatch.

I also install a second sheet of FRP on the inside, good side in as a finish.

2 sheets is more than enough, then sheath the outside with Aluminum.

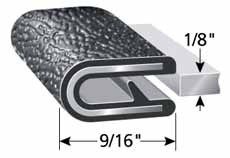

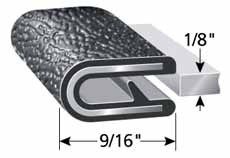

I seal the outside edges with this;

I know, I know. But doesn't water get into the sides?

No! I build the sides in 3" at the hatch, and run the outside corner molding straight through. This is a very common area for leaks. The FRP/Aluminum extends 1 1/2" past the galley opening and I put a second outside insert molding on the inside of the galley.

This insert molding is 3/8" tall with a vinyl insert that acts as the hatch's seal. Plus I extend the offset Hurricane hinge past the galley opening.

For the water to get in it has to run down, make a right or left hand turn, run up hill and jump over a 3/8" tall molding that is under the FRP/Aluminum.

In addition the 2 outside corner insert moldings create a good Trough for the water to run down there by directing the water out and off the trailer.

Plus I extend the offset Hurricane hinge past the galley opening.

These shots are from 3 different trailers of mine, but the theory is still the same.

Happy Trails

Len

want to know your experiences.

want to know your experiences.

Danny

Danny