ok i have two questions relating to each other

i have built my chassis it is a set width 1550mm and length 2400mm to late for change now

1 my plan is to use 25 x 25 mm box section to from the profile of the side of my TD then weld that to my chassis brace it then sheet it from there but i no longer have to tools to roll the box my self after work closed down now the profile i have decided on is two sectioned eclipse but every shop i have gone to tells me its to hard

so i was wondering if there was any way to bend roll the profile i wont without the tooling

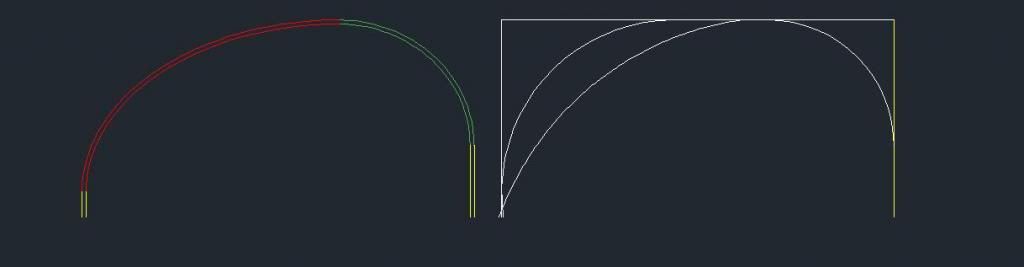

2 failing that i have redrawn the profile and made it from radiousses this will make it easy for the shops to do the work but it limits the room i was saving for a gallie meaning it might not be worth wild making a rear hatch if i dont have a gallie so i am after a quick poll drawing on the left or drawing on the right the one on the right has two options the top profile or the lower profile

thanks for any input

Fred

Fred

The rollers can also be machined by any competent machinist. My son has made some. No, he does not sell them. However they do work and if you look at the investment in the machine and a set or two of rollers as just being another useful cool tool you can justify the cost to yourself. Swag also sells a tubing roller.

The rollers can also be machined by any competent machinist. My son has made some. No, he does not sell them. However they do work and if you look at the investment in the machine and a set or two of rollers as just being another useful cool tool you can justify the cost to yourself. Swag also sells a tubing roller.