Will a 4x8 TD be stable without the rear galley?

15 posts

• Page 1 of 1

Will a 4x8 TD be stable without the rear galley?

Thoughts/experiences appreciated.

Considering my wife's vintage business the TD design really fits in well with her small companies' general theme.

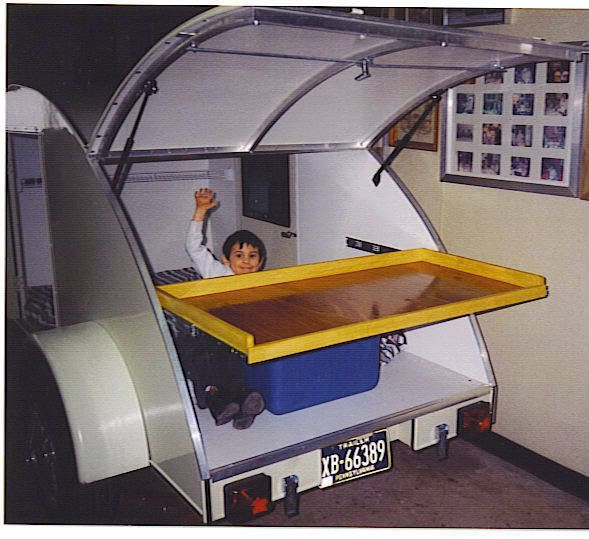

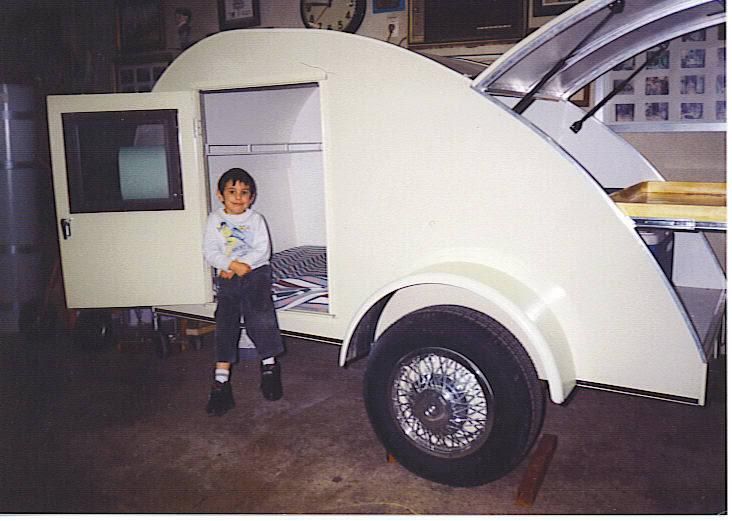

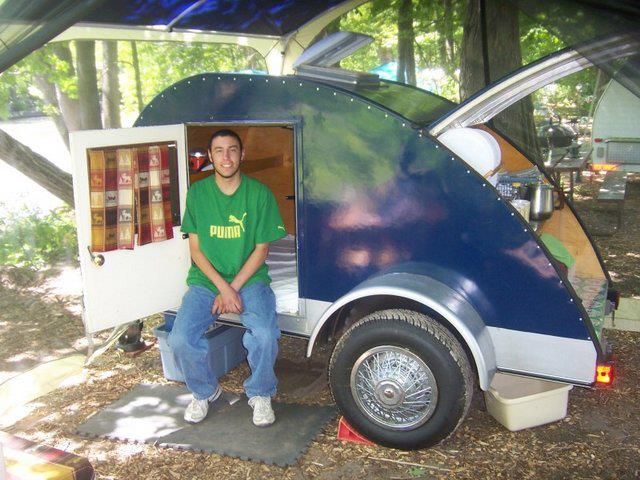

So I want to build a TD primarily to haul her display stuff to her weekend shows but also be smart enough to convert to a camper for summer trips (since my wife won't backpack/remote camp w/me:)).

So, wondering if the 4x8 HF TD will be structurly stable WITHOUT a rear kitchen galley? I just have visions of it collapsing since the rear galley cabinets seem play a key part in keeping the TD upright.

I might consider building a completely removable galley or maybe just a plywood brace on the top half to leave the floor open the length of the trailer (7-8').

Thanks!

Considering my wife's vintage business the TD design really fits in well with her small companies' general theme.

So I want to build a TD primarily to haul her display stuff to her weekend shows but also be smart enough to convert to a camper for summer trips (since my wife won't backpack/remote camp w/me:)).

So, wondering if the 4x8 HF TD will be structurly stable WITHOUT a rear kitchen galley? I just have visions of it collapsing since the rear galley cabinets seem play a key part in keeping the TD upright.

I might consider building a completely removable galley or maybe just a plywood brace on the top half to leave the floor open the length of the trailer (7-8').

Thanks!

- Triumph3

- Teardrop Inspector

- Posts: 5

- Joined: Thu Jan 09, 2014 6:08 pm

Re: Will a 4x8 TD be stable without the rear galley?

You should make the the sides of the hatch slide within the walls to lock the wall square when driving and install some angle brackets like these.

http://www.hiwtc.com/photo/products/19/00/07/744.jpg.

http://www.hiwtc.com/photo/products/19/00/07/744.jpg.

- KennethW

- 1000 Club

- Posts: 1188

- Images: 82

- Joined: Wed Feb 20, 2013 8:01 pm

. I have the trailer and base built and that's a good stopping point for a day or so while I plan this.

. I have the trailer and base built and that's a good stopping point for a day or so while I plan this.

. This forum is similar to

. This forum is similar to  ). Lotsa quality feedback.

). Lotsa quality feedback.