Thanks for the input. I'm glad to hear that some think it is too beefy. I don't want to under-build, but at the same time I'd like to avoid over doing it.

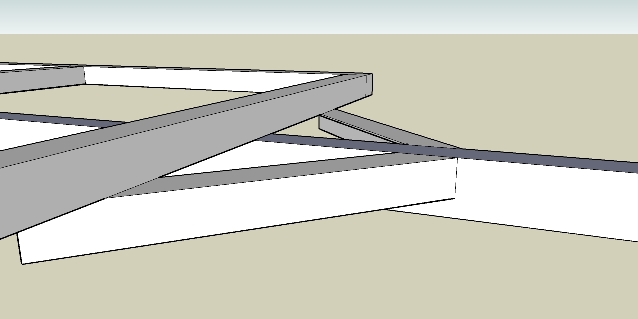

Asianflava: I am expecting the front arc to overhang, but only as low as the rectangular frame. The tongue (and the a-frame) would be welded under the frame, like so:

Hopefully this makes it less of a headache.

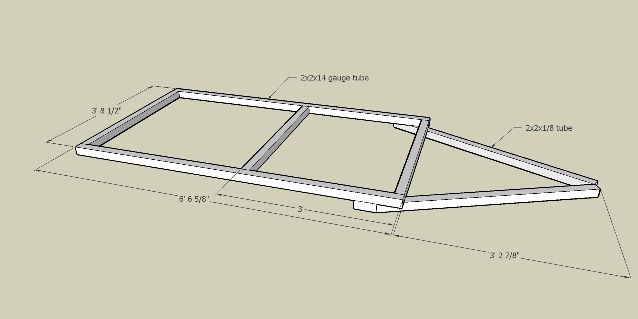

Here is another version I'm considering which would allow doing away with angle bracing. It also incorporates 2x2x14gauge as recommended, hopefully saving money and weight.

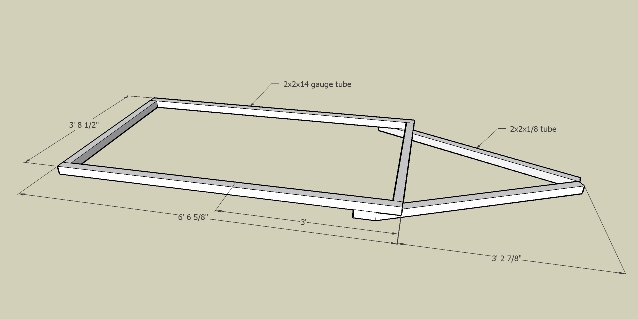

Or an alternate version leaving out the x-member:

This seems to be the simplest and (hopefully) plenty strong enough. I'm having a professional weld it, figuring it's not the place to scrimp. This should make using a lighter gauge ok. Thanks again.