He seems to like it

:

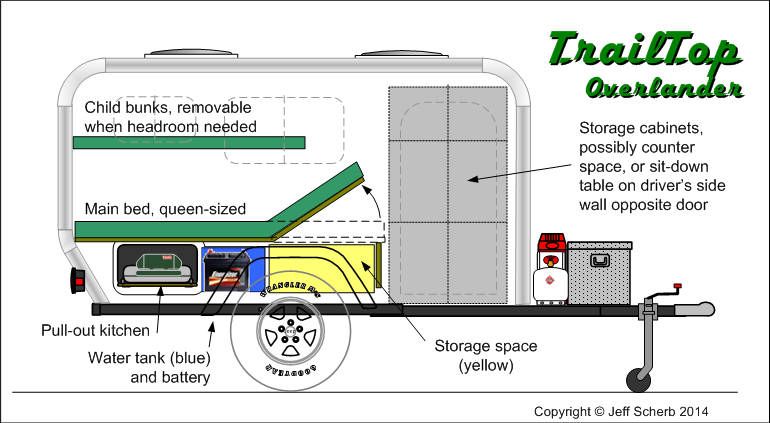

:Wow!! That is perfect! I love it! Thanks for the drawing and I truly do hope you can find someone to bring these things to market, even though that's not your ultimate goal I know. This would be a perfect trailer for my family!

:

:Wow!! That is perfect! I love it! Thanks for the drawing and I truly do hope you can find someone to bring these things to market, even though that's not your ultimate goal I know. This would be a perfect trailer for my family!

Cargo-Lite trailers are neat too. They have a window and door on each side and a ramp for the back door.

I have been jonesing for one. It would be neat with a rooftop tent.

[/URL]

[/URL]

rowerwet wrote:unless it is painted, FRP isn't UV stable, Filon is the version of FRP that is stable it seems to be easier to find in areas where RV's are made, expensive to get for the rest of us. If I was building using your awesome corners I would cover the plywood with painted canvas.

Socal Tom wrote:rowerwet wrote:unless it is painted, FRP isn't UV stable, Filon is the version of FRP that is stable it seems to be easier to find in areas where RV's are made, expensive to get for the rest of us. If I was building using your awesome corners I would cover the plywood with painted canvas.

I've heard that, I've also heard the opposite. Do you have a source for the info?

Tom

Users browsing this forum: No registered users and 6 guests