Starting Design-Asking for Trailer Review

42 posts

• Page 3 of 3 • 1, 2, 3

Re: Starting Design-Asking for Trailer Review

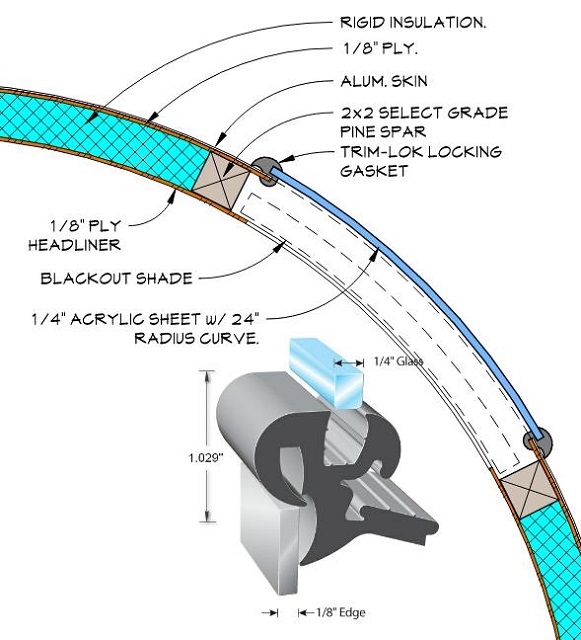

Yes, similar to VW seals. Here is my best guess using a TrimLok product. I was mostly concerned about its application on thin plywood. But based on the examples I have seen, it should work ok.

Erik

Build Journal: http://www.tnttt.com/viewtopic.php?f=50&t=71294

Build Journal: http://www.tnttt.com/viewtopic.php?f=50&t=71294

-

eLink - Teardrop Master

- Posts: 191

- Images: 142

- Joined: Mon Nov 12, 2018 3:34 pm

- Location: Los Angeles

Re: Starting Design-Asking for Trailer Review

eLink wrote:Yes, similar to VW seals. Here is my best guess using a TrimLok product. I was mostly concerned about its application on thin plywood. But based on the examples I have seen, it should work ok.

Thanks for posting that image. My concern with that technique of mounting a sheet of plastic like that is the spring back (memory) from the plastic. I just don't know if that will put enough force on the rubber gasket to kind of want to pull it out, or otherwise stress it. I suppose the thickness of the plastic plays a part. I would love to find a vendor who can heat bend Lexan. That would work well, I think. If you're using .125 plexi, maybe it's not an issue, bending it like that.....but

.250 material, just not sure. I saw another build that used .125 Lexan but didn't use a rubber seal.... they seemed to have held the Lexan in place with aluminum trim, screwed the trim down, trapping the Lexan..... and I imagine using a urethane sealant of some sort.

"Success can be defined as moving from failure to failure without loss of enthusiasm".... Churchill

Visit my Teardrop build here: viewtopic.php?f=50&t=73779

Visit my Teardrop build here: viewtopic.php?f=50&t=73779

-

Capebuild - Donating Member

- Posts: 767

- Images: 130

- Joined: Sun Jan 31, 2021 6:50 am

- Location: Massachusetts

).

).

Very nice! Looking forward to seeing your construction progress.

Very nice! Looking forward to seeing your construction progress.