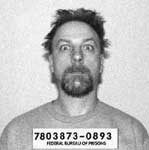

a quick search on your name, or convict avatar should yield the thread that I read...

You got to admit, with an avatar like that, who can forget you.

Sorry to hear about the layoff.

I was laid off in Jan 2006. First time ever btw...

but there's work out there, as long as you are not in MI.

Mike...

Another Generic Benroy - SaGR's build

70 posts

• Page 4 of 5 • 1, 2, 3, 4, 5

mikeschn wrote:a quick search on your name, or convict avatar should yield the thread that I read...

You got to admit, with an avatar like that, who can forget you.

Sorry to hear about the layoff.

I was laid off in Jan 2006. First time ever btw...

but there's work out there, as long as you are not in MI.

Mike...

hmmmm......this might be interesting.

This is the first time I have ever been laid off too, I don't like the feeling.

Ed

-

Chaotica - Teardrop Master

- Posts: 192

- Images: 22

- Joined: Fri Aug 25, 2006 9:02 pm

) I'm not too upset, things will work out in the end.

) I'm not too upset, things will work out in the end.

We can all agree on something before my dumbazz goes and does something stupid!

We can all agree on something before my dumbazz goes and does something stupid!