Routing wires under the trailer.

16 posts

• Page 1 of 2 • 1, 2

Routing wires under the trailer.

This is such a basic question I'm almost embarrased to ask it. However, my trailer frame is a little different than most of the ones I've seen here.

In addition to the trailer light wires, I will also have the 12 volt wire from the battery on the tongue.

My trailer frame is welded from 2 1/4" tubing, so there is no channel into which I can insert the wires or conduit.

Shoud I:

1) Just staple the wires to the bottom of the 3/4" solid plywood floor; routing the wires under the tubular cross members?

2) Screw 1/2" PVC conduit sections to the bottom of the floor between the cross members; routing the wires under the cross members without conduit?

3) Add 2 1/4" spacers to the bottom of the floor and route the conduit the full length from the tongue to the rear of the frame.

4) Do you have a better suggestion that I haven't thought of?

I do intend to add insulation under the floor.

As always, thanks for your help!

In addition to the trailer light wires, I will also have the 12 volt wire from the battery on the tongue.

My trailer frame is welded from 2 1/4" tubing, so there is no channel into which I can insert the wires or conduit.

Shoud I:

1) Just staple the wires to the bottom of the 3/4" solid plywood floor; routing the wires under the tubular cross members?

2) Screw 1/2" PVC conduit sections to the bottom of the floor between the cross members; routing the wires under the cross members without conduit?

3) Add 2 1/4" spacers to the bottom of the floor and route the conduit the full length from the tongue to the rear of the frame.

4) Do you have a better suggestion that I haven't thought of?

I do intend to add insulation under the floor.

As always, thanks for your help!

Dave

If a man says something in camp, and no woman is around to hear it...Is he still wrong?

If a man says something in camp, and no woman is around to hear it...Is he still wrong?

-

Looneytoons - Teardrop Master

- Posts: 137

- Joined: Tue Oct 06, 2009 2:36 pm

- Location: Evans City PA

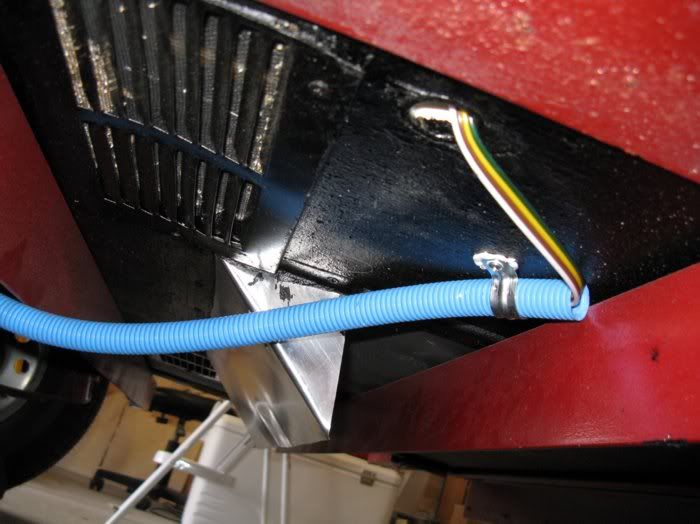

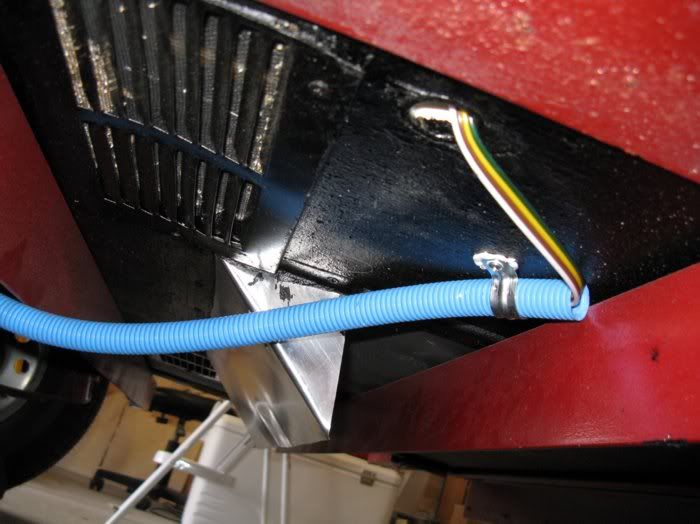

I used blue flexible conduit that I got from Lowes. It worked great for my application. The pictures show just one but I eventually ran 2 lines, one for 12V and one for 120V.

Conduit link

Conduit link

Mark (& Cindi)

Mark (& Cindi) Visit our website: Little Swiss Teardrop

I was wondering why the water balloon was getting bigger... and then it hit me.

-

planovet - The Cat Man

- Posts: 5583

- Images: 3

- Joined: Tue Nov 27, 2007 4:48 pm

- Location: Plano, Texas