1"x2"x.188" Steel Frame/Axle Concern

16 posts

• Page 1 of 2 • 1, 2

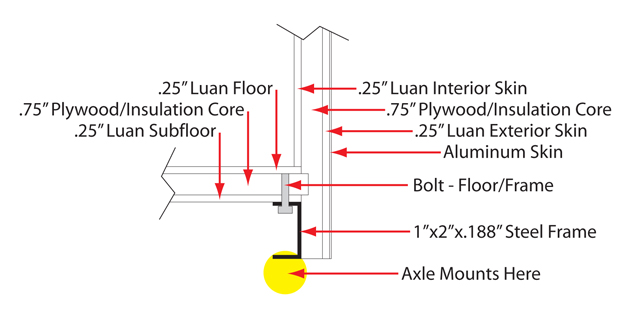

1"x2"x.188" Steel Frame/Axle Concern

I have thought, rethought, and re-rethought out ever aspect of this thing about 4 or 5 hundred times, I am getting ready to jump into the build phase. I had my mind made up I was going to use 2"x2"x.125" square tube for the frame, but after seeing everyone talk about how overbuilt most of these end up I am leaning more towards 1"x2"x.188" C-channel for the frame. I don't worry about it being strong enough especially with adding a dado in the side walls, but is 1" going to give me enough beef on the frame to weld/bolt the axle to the frame? I plan on using a torsion axle (and there are going to be plenty of questions prior to ordering that, as I really don't understand that angle/ride height/tire size thing, but more on that when we get there). By going with the c channel rather than the square tube I save about 30 pounds and about half the cost of the steel. I would appreciate all thoughts/concerns/comments, don't hesitate to call me a knucklehead if you see something that doesn't seem right.

-------------------------------------------------------

Listen to what I'm thinking, not what I'm saying.

Listen to what I'm thinking, not what I'm saying.

-

RichAFix - Teardrop Master

- Posts: 114

- Images: 10

- Joined: Sat Feb 03, 2007 2:15 pm

- Location: Milwaukee WI

RichAFix,

You do not have to have the luan on the exterior of your floor. Also remember there will be cross members for your frame that will add stiffness to the c-channels for the sides. I think you should be fine with the thickness of the metal but I am no engineer, there are others that can give you a better answer.

You do not have to have the luan on the exterior of your floor. Also remember there will be cross members for your frame that will add stiffness to the c-channels for the sides. I think you should be fine with the thickness of the metal but I am no engineer, there are others that can give you a better answer.

Rick

If ducks had scales, would fish quack?

If ducks had scales, would fish quack?

- rbeemer

- 500 Club

- Posts: 997

- Images: 13

- Joined: Sun Apr 03, 2005 11:35 pm

- Location: Oregon, Tigard