crumbruiser wrote:I really like the thrifltyness of your ways. Having a lathe would be great and finding all of that wood is fantastic! Have fun turning it and making all of that mulch.

Frank

Thanks Frank, I was telling someone again recently, it is not always about being able to afford or not being able to afford, but rather about making the choice to make a bit of effort that keeps money in my pocket... and that makes me feel great.

In the mean time.....

Right where do I start??

Had an electician here for 5 hours today at £25/hour to wire the shed up to the mains via a 6mm armoured cable and to fit a consumer unit (Not sure thats the right name for a distribution box)

By the end of the day at 3pm I had 8 plugs linked to the mains and could work any of the machines or lights I have in the shed.

He will be back next Saturday to fit a 4ft strip light and rocker switch at the door, probably another £50.00, then all the wiring and lighting should be done.

Personaly, I would have love to do it all myself, but Nicola put her foot down and said we need a wiring certificate, in case anything ever went wrong.... so I capitulated and did other stuff while Mark sorted the electrics out, the upshot was that I got a bacon sandwich at lunchtime when she fed Mark.... yahoo !

Did I mention that there was a bit of candle holder envy from Nicola's mum after she claimed the first item as a candle holder??

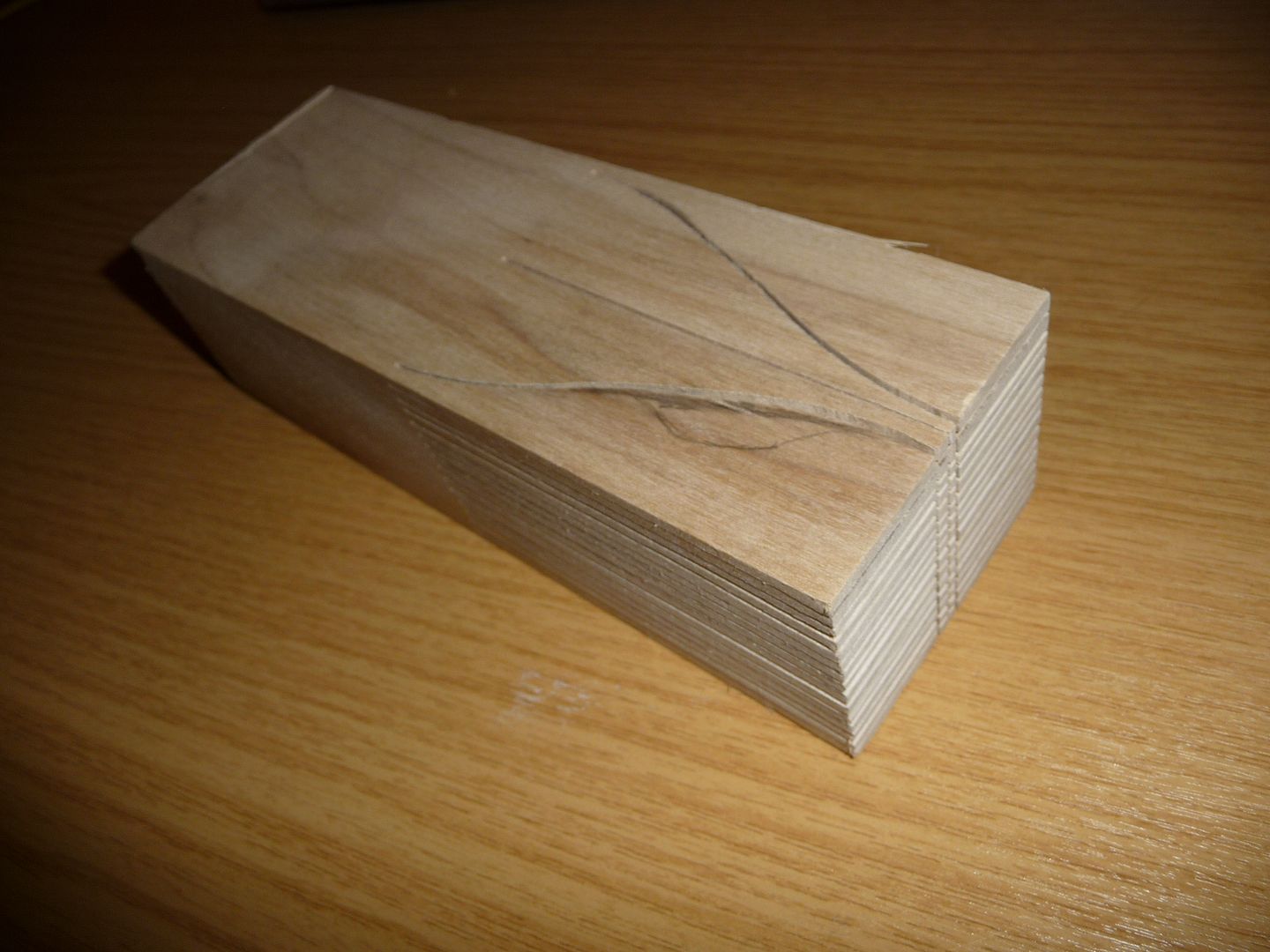

So I decided to make her something nice out of Tulip wood.

Started by measuring out on the wood I had and then cutting out on the bandsaw, after which I used woodglue to laminate the two bits. I will let them dry for 24 hours, which is way more time than needed, and then turn somethig like a candle holder.

Measured and drawn.

Cut out...

After this I cut the grass and kept busy while the shed was being wired.

Once Mark left, I took a bit of what I asume is Sapele Mahogany and started turning some stuff that was on my mind.

I initially tried to make the two right hand knobs with grooves cut in, like the first plate, but it did not work for me, so I re-cut and reshaped them. followed by sanding.

It seems mad, but up to that point took me 2 hours, as mentioned by someone before... wood turning absolutely sucks up time.

Finally after cutting them loose, I had 3 gearknobs.....

HANDMADE and UNIQUE.

I am prepared to sell them on here or elsewhere at what is hopefully sensible money.... at £7.50 each incl postage, unless you want to collect, in which case they are £6.00 each. This is in the UK by the way.

I have marked them 1,2,3 and have not drilled them as various applications will have different shaft sizes.

If interested, please PM me and say which one you want.

I will deal with it straight by time of PM arrival, so if 3 people want the same one, the first PM gets preference.

I want any interested parties to note, these are hand made and not perfect like a factory moulded or mass produced knob. In future I will experiment with adding tops to them as well.

Front/top views.

Bottom, to show the numbers and what you will have to deal with when drilling a hole.

Please note, the Pound coin is just there for illustration.

LAST THING ......

A Captive Ring (I thought it sounded rather rude)

I made this one just to prove to myself and also to try out a custom tool I have made up, to be able to cut around corners.

Hope you like the updates.

Please do leave comments about the knobs and pricing, or send me a PM if you want to be really honest.

Thanks for looking in.