You're looking for advice, eh? My advice is not to build any stress risers into foamie walls.

Alright, so how do you do that? One way is to have your framing extend into the foam.

If I was doing it again, I would laminate my framing into the foam.

But my repair is a very close approximation of how I would build...

And for those of you who are following my repair...

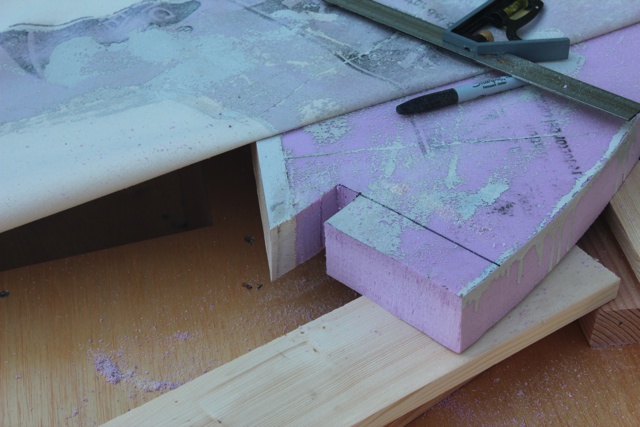

Here I am gluing up the framing. Once it's dry I'll cut it to length.

Here's I've used wood glue and a screw. The wood glue was only a dab where the wood touched the wood. Everything else was gorilla glue.

I really like gorilla glue. You can do a complete repair in a fraction of the time that wood glue would take. Here I've glued in the new foam. Once it sets up, in about 1/2 hour at today's temps (80 degrees) I'll trim off the excess, and think about painting it again.

Mike...

P.S. Coming up next, the shrink test...

P.P.S. I want you guys to know I had a hard time peeling off the canvas...

The quality is remembered long after the price is forgotten, so build your teardrop with the best materials...

oh mike, that is horrible.

oh mike, that is horrible.

you think the canvas should go on after the shell is done?

you think the canvas should go on after the shell is done?

I had assumed you'd be doing the plywood skin on the inside which would have provided plenty of support for that configuration ...

I had assumed you'd be doing the plywood skin on the inside which would have provided plenty of support for that configuration ...