GPW,

No excuses, just trying to put some “love” into this thing. A semblance of craftsmanship. Simplicity in its most complicated state… or is that the other way around?

Funny you should mention storage, and Randy talking about selling motorcycles. Lately I’ve been thinking about what I might do after finishing TPCE (aside from going camping). This includes casting off several old “projects” that are languishing; the boat, the bike, and the tuner car. That will free up some space. I’d like to get the red truck back up and resembling something nice, and have long threatened to replace the bike with another ‘wind in your hair’, but more comfortable ride, like a scratch built roadster!

Randy, life is but a series of choices and where there is a will, there is a way, so if you put your mind to it, you can find a way to have that scooter and get back in the wind. The sale of the BMW’s will surely generate some cash, and if the ‘new’ scooter is too big of a stretch, take your time and find a good deal on a used one. Another option that could be fun is to find a vintage scooter and do a little resto on it. Redirect your stove and lantern hunting fun money for a short time and the scooter could be all yours (then go back to the WGA’s, of course!).

With hobbies and toys, more often than not I tend to wade in the shallow end of the pool; make sure the water is right before jumping in all the way in… and sometimes never getting in past the knees. Two reasons; first it’s hard to justify the full blown cost of some hobbies. That $4m deep sea racing boat with triple blown big blocks, or going top fuel racing are “just a bit” out of my reach (…that’s sarcasm…), so my little 16ft ’67 Sea Ray with chalky paint and cracked transom, and the now sold Chevelle have acted as substitutes. Second, there are a lot of things that interest me and it is hard to justify a truly big commitment in time and money in any one field of interest. Though the effort I’m putting into TPCE is the start of a new level of commitment; if I want it I have to get off the couch and work on it.

Just a few hours of work today. Scuffed the front of the locker door and put the last coat of poly on it.

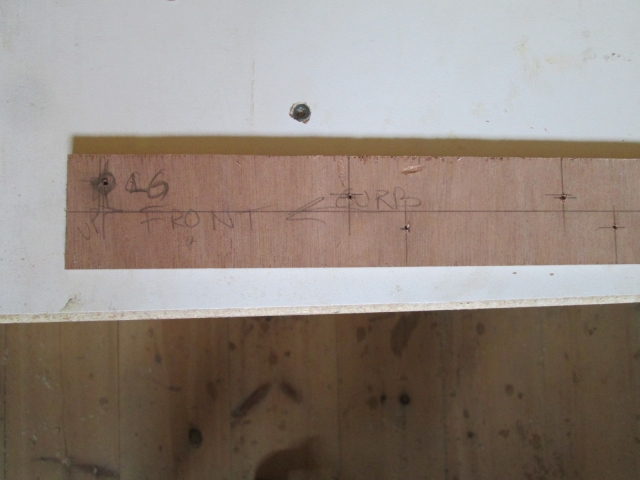

That put the kibosh on running the fan or stirring up sawdust, so I tinkered on the splice piece for the front wall to front ceiling panel joint, laying out the screw hole pattern.

The upper portion will get glued to the lower edge of the ceiling panel, then when it comes time to attach the ceiling to the cabin the lower portion, or flap, will get glued and screwed to the front cabinet ledger. The horizontal line represents the seam between the two panels. The screw hole in the upper left (and corresponding far right) will go into the wall blocking, and the staggered pattern will land between the screw spacing at the top of the front wall. I staggered all of these screws to save the integrity of the relatively small cabinet ledger. Wouldn’t want it to split apart or have screws pull out because they were on top of each other.

Rather than kick up dust flipping ceiling panels around, I called it quits for the day. On the way home I stopped at the local farm stand for a Miracle bar and sat down by the river for a few minutes to enjoy it.

Drags are in Epping, NH this weekend. Had brief thoughts of going up to see them, but will save that for another time when I can drag the camper along and stay for the duration.

No thoughts on the coat hook dilemma? I put the question out there to a bigger audience

here.

Also, I’m trying to decide if I can stain and poly the ceiling panels in the flat and then successfully bend them at installation, or if the poly will make them harder to bend and I should preform them first; so I put that up for discussion

here.

Randy

Randy

Randy

Randy KC , you don’t need excuses , you have the Proof !!!

KC , you don’t need excuses , you have the Proof !!!

.....

.....

.....

It’s really taking shape now , looks Great ... I can visualize it finished ...

It’s really taking shape now , looks Great ... I can visualize it finished ...  Gonna’ be COOL !!!

Gonna’ be COOL !!!

.....

I go through alot of tape measures.

I go through alot of tape measures. (I guess that I am the "tool"!)

(I guess that I am the "tool"!)