Today was all about detail work on the hatch spars, both upper and lower. I Started by laying out the hatch lower spar on a piece of 1x4 Maple that had been cut to approximate length previously.

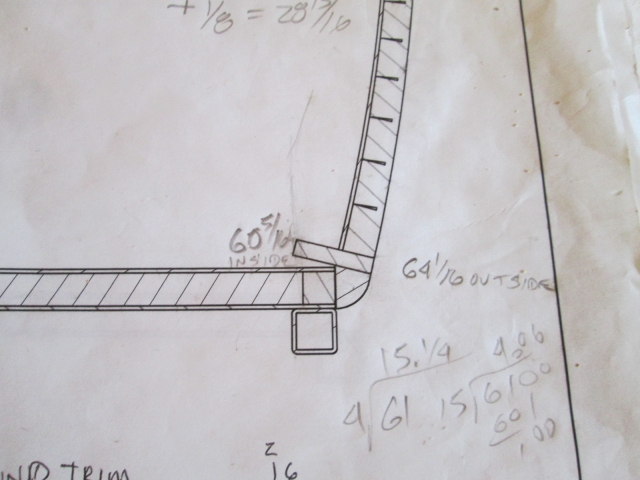

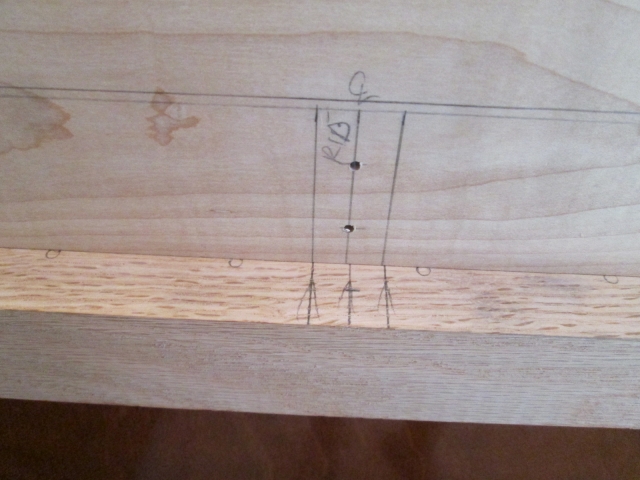

In this picture of the plan you can see this lower spar that will be screwed to the bottom of the hatch rib tails (tails penciled in).

These shots from the computer model show it better. The hatch lower spar is shaped sort of like a wide flat muffin, with the lip of the muffin top wrapping around the ends of the walls.

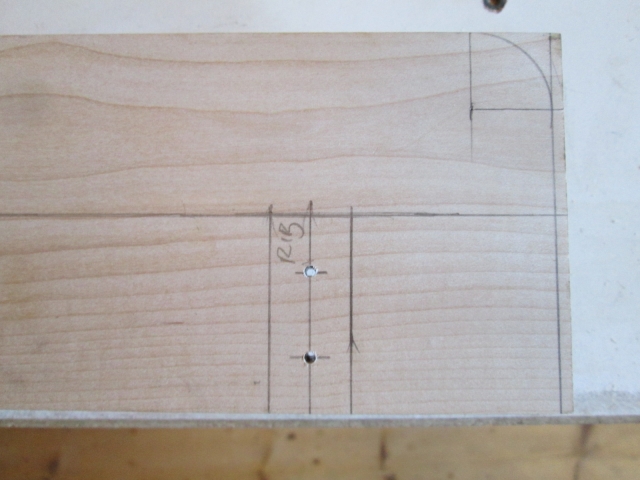

Here’s a shot looking down at the street side end of the lower hatch spar. The 3/4 inch radius is the same line that carries all along the wall to roof edge. The rectangular area with the two pilot holes is where the street side hatch rib will be attached, and the square area to the right of that will get notched out here shortly.

I drilled a small hole in the corner of each notch before cutting them out so that there would be an inside radius in the corner.

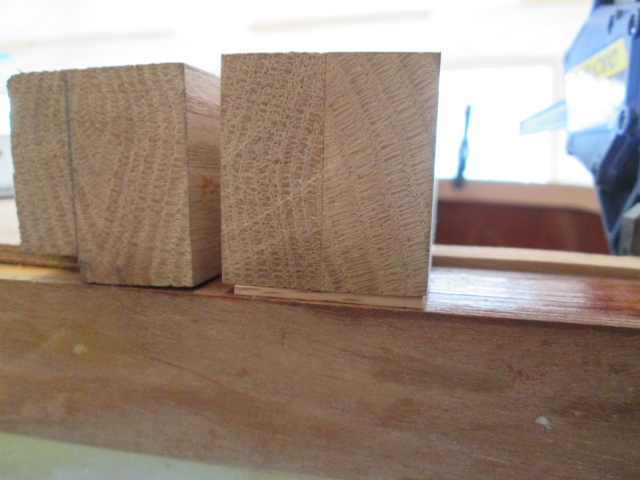

Here I am doing a quick check just holding the lower spar up against the bottoms of the two side ribs and the backs of the walls; street side.

Street side from the side.

It looks like it is going to end up about a 1/4 inch higher than planned. I’ll have to check and make sure that there is enough meat in the lower sill blank to make this up, otherwise I may have to add something somewhere.

After thinking about the hatch build sequence for some time I have known that I was going to have a conflict. If I join the two inner skin blanks together on the bench to get a nice clean nearly invisible seam, then I would have no way to put the skin on with the frame in place in the galley because there would be no way to clamp it, and any temporary screws used to hold the ribs to the side walls would be inaccessible to remove once the skin was installed. So while noodling this over again playing twenty questions with Karl, he came up with the start of a great idea, and I figured out the rest. If I temporarily screw thru the top ends of the hatch hinge spar down into the tops of the walls, those screws would be accessible to remove after the skin goes on. At the bottom I can attach a couple of temporary cleats to the underside of the lower spar so that I can screw thru from the rear into the lower rear edges of the walls and get to those screws after the skin is on, as well. So thanks again to Karl for helping me work thru another sticky step in the build process!

Here is a pic looking down at one of those extra temporary screws thru the curb side end of the hatch side spar (on the left) into the top of the wall.

To allow a little room for the canvas that will fold under the part of the hatch that will overhang the walls, I used a little sliver of the oak (conveniently the discarded piece from the cabin side hinge spar rabbet) as a shim to hold the hatch side hinge spar up about 1/16 inch.

Using a piece of scrap as a straight edge shows that I will need to plane the hatch side hinge spar down a bit so that the hinge will lay flat. I probably should have allowed 1/16 over on my hatch rib template, but will tweak everything a little and try to get this to work the way it is.

I went back and countersank those temporary screws so that the plane will be able to pass over them.

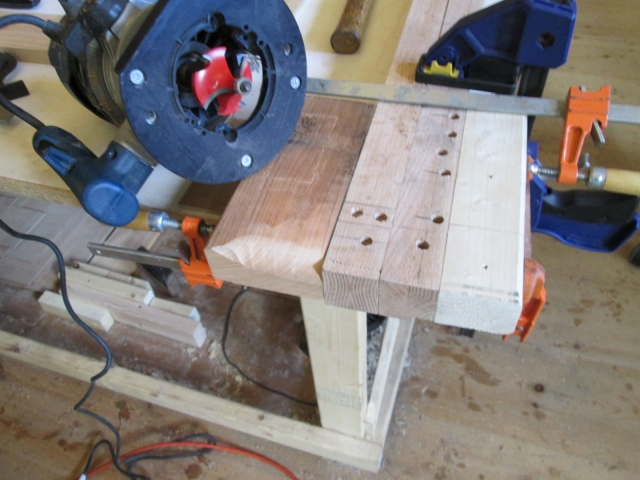

After laying out the locations for the two middle ribs on the upper and lower spars, I put the lower spar up on top of the upper spar just as a dumb-idiot-check to make sure they both lined up before drilling the holes in the upper spar. Here is the street side and one of the middle rib locations.

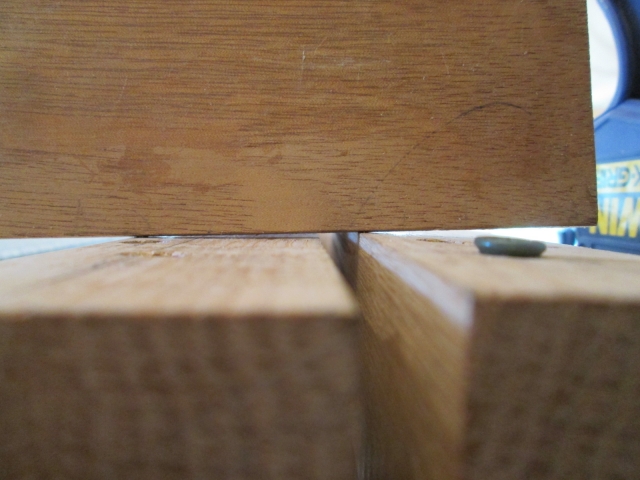

Next I removed the spars and worked on rounding over the edges. Here is the clamp set up for the router with blocks on either side to help support the router base and avoid chip out.

I had hoped that the temporary screw hole (used to pin alignment when I glued up the spar blanks) would have been cut away by the radius, but no luck. I’ll have to use some filler on it. “Missed it by that much.”- Maxwell Smart

The other end came out better.

Set back up on the cabin for a look see.

Same technique used for the lower spar.

Here you can see one of the rib tail locations on the lower spar with the rib template laid over the top. Note how the tapered side of the template doesn’t meet the edge of the spar flush.

So I used a straight edge to draw a new line parallel to that edge that does meet flush; then cut the template back to the line with a razor knife and steel straight edge. I’ll use the template to correct all of the rib tails accordingly.

And that’s where I got to today.

). So I moved the centerline deeper onto the bulkhead, flipped the pattern “over” to the other side of the seal trim hole marks and drilled another series of holes. This set was better aligned on the bulkhead center, but I had forgotten to double check against the ceiling skin screws.

). So I moved the centerline deeper onto the bulkhead, flipped the pattern “over” to the other side of the seal trim hole marks and drilled another series of holes. This set was better aligned on the bulkhead center, but I had forgotten to double check against the ceiling skin screws.