Mike, goofed with the radius cutter today. Haven't figured out the transformer stuff (I think electricians are wizards) yet so I played with the soldering gun.

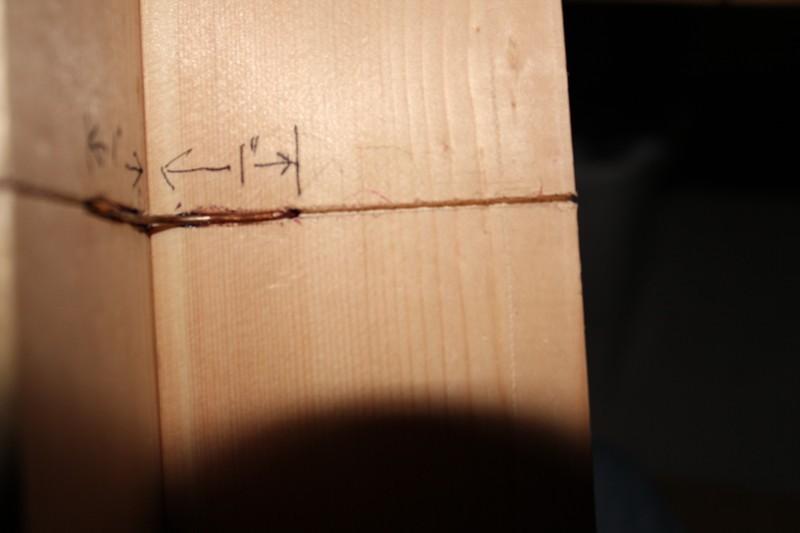

Took some 1x3, - measured down 4" and cut a kerf (1/16" about 4 light passes)) with a hand saw which just happens to be a touch smaller than the #12 ground wire I used for the cutter.

Screwed boards on edge, on the inside measured out 1" along kerf on each side and drilled a 5/64" hole (the size of the ground wire).

Turned plate over and centered soldering gun holes over the drilled holes and clamped solder gun down solid with screws and plumbers tape.

Strung the wire through the two holes out the sides and loosely fit into soldering gun. Got myself a 1" piece of dowel and used it to shape my radius (whacked it with a hammer). Centered wire in the kerf and tapped it in so nothing was sticking up above the cutting plane (goofed up here by not paying attention and a corner of the wire did not get tapped in - left a 1/64th depression about 1/4" below bottom of radius).

Tightened up the wire in the gun, plugged it in and .... had to do it twice, I found that the cut had smoother results when pulled rather than pushed.

The pics are in the album but I'll post them here for a week or so and then remove them (I'll leave them in the album) so they don't take up so much space.

My experience was that the unit pulled along the surface well and stayed flush in both planes and the feed rate seemed like 1-1/2" per second. There were no dips, grooves, etc during the cut. I'm not sure if the 'blemish' (from not having 1 cutter wire seated properly) would show up after taping the edges or covering the faces. The radi can easily be shaped to whatever is wanted - the ground wire is soft yet will hold the shape and is easily tooled to whatever increase in radi is wanted.