alaska teardrop wrote:jonnyo wrote:i m thinking around 1000lbs empty.....but we never put more than 100-150lbs of luggage max so i expect it to be in the low 1000s. In that case, you would probably want a #9 rated at about 1500#s. But here is a suggestion. Build your trailer, weigh it (empty & loaded with gear) & then order your axle accordingly.

i think my best bet at this point is to go to the trailer dealership, and look under some of those Aluma, mission, cargo pro all aluminum utility trailer and see what size and tickness tubes and design they used. no point in reinventing the wheel.... Please become our resident expert on building a small camping trailer with an aluminum chassis. Like, while you're checking out those trailers, ask about & get details to share. Are the tongues designed to a standard engineered formula? Alloys? Extruded shapes & sizes relative to the anticipated load ect. ? Close up pictures of where the tongue rails meet the front floor/cabin? And of course the welds. Thanks, Fred

.

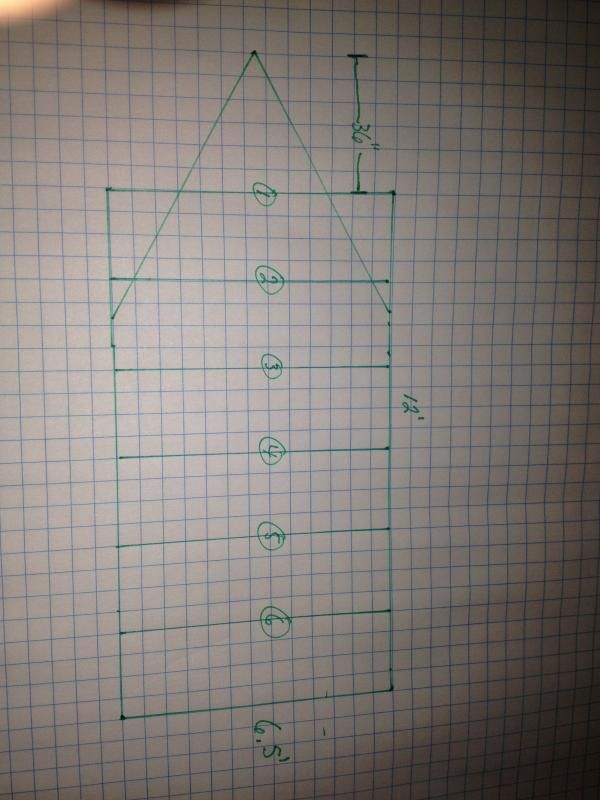

It would be cool to see a sketch of your cabin plans - profile/floor plan/galley ect.

Well, the investigation as been a lot of fun so far. I come from the bicycle industrie and have work in the design of bicycle. We can make anything out of aluminum and Steel isnt competitive with well engineer aluminum design. it s not even a close match. So, it s interesting to see the way the company make those aluminum trailer.

my big realization. if it s a enclose trailer...they use much smaller tube for the chassis compare to the same weight/dimension rated utility/open deck trailer. For exemple, cargo pro all alumium enclosed trailer 6X12 beleive they can get away with light 2X3X1/8 chassis and 1X2X1/16 wall and roof.... but for the same exact model in utility trailer with no wall or roof, they have to go with a 4X2X1/8 and reinforcement. Aluma make huge double single tongue... there is a bit of everything! lots of very clever design......

i pass a good 20minutes under those trailer looking at all the details....the dealer though i was funny. That said, the dealer had very little good info to give on design...they dont know there product. that well. i might not have had the best sell person...

That said, i have found amazing knowledge in Bill at

http://www.expresstrailer.com/ he is ''local'' to me, and he loves custom work. he was very generous of his time and sharing idea and recommendation on what to do and not do. I m considering having him build the main frame so i have peace of mind and can build the walls structure, roof etc but at least...main frame, tongue, axle done professionally.

they make amazing work and he is excited about any custom project.

For me, he recommend 2 option:

6.5X12 all aluminum lightweight axle, chassis similar to a utility trailer... (6.5 because you can put the adult bed sideway...) he said anything longer than 12 on a single axle make for a complex engineering problem with aluminum.....reliability become a issue.

or

a lightweight...but dual axle 6X14 with light rated axles(think a mini tandem)...and he said that would make it very easy to build with no flex of the aluminum and very good weight distribution...making aluminum design easier with 2 axle. this as advantage of not been as wide...hide better behind the car, very easy to tow etc. (anyone on here ever done a tandem teardrop??? good? bad? i m open minded so dont reject any ideas..)

i will draw the interior and exterior shape....and share. but really, there is no limits.....well, budget is 4-5k !

Fred

Fred