Okay, where was I? Oh yeah, Monday night I shortened the safety chains and worked on the fenders some.

Karl had thought that I should be able to use a couple of large adjustable wrenches to twist the S-hooks apart and remove them, but due to the angle of the closure, the wrenches could not be held parallel and wanted to twist out. After smashing my hand pretty hard, once, I found a better way.

I clamped the S-hook to one of the front rail verticals to hold it securely then used the big wrench to lever the pinched end sideways.

A little tweak with a big pry bar and that was just enough to get the chain link out, no more.

The chains needed to be about 10 links shorter, which left few places to clamp it securely while cutting, but I managed to nestle the link to be cut in behind the jack mounting clip in a way that I could cut both sides of the link w/o having to reposition.

The chains would no longer reach back to the front rail so I used a length of 1x3 rectangular steel tube strategically placed under one of the front rail vertical supports and over the tongue to where I could slip the S-hook into the end and pry downward.

To get the tag end of the hook to close that last little bit I placed a piece of 2x4 on the concrete floor with a chunk of steel on top to use as an anvil. Mini sledge and a vice grip took care of the rest.

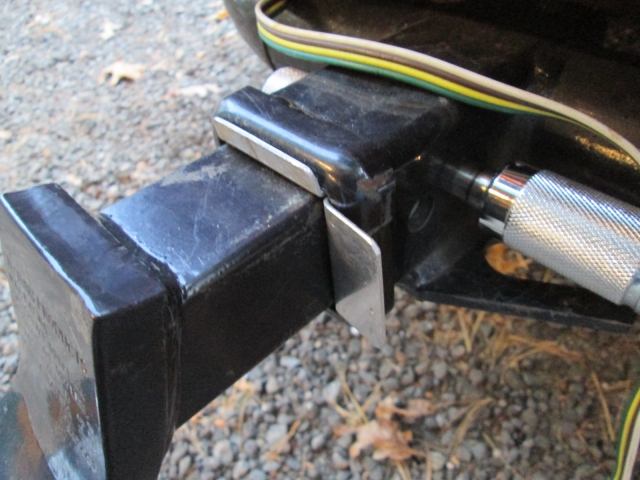

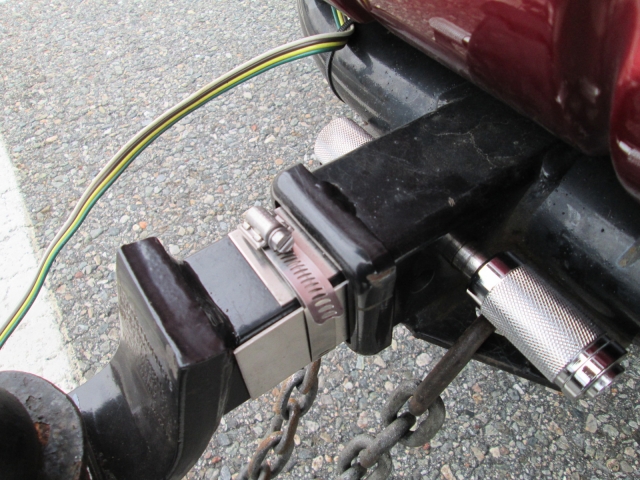

With the tongue being so light, especially when empty, I was getting a lot of clunking at the hitch, so I made a couple of 1/16 thk aluminum shims and stuffed them in tight.

I brought the trailer home with me (since my next move was to go for inspection after work on Wednesday) and they didn’t seem to do a whole lot. In fact I heard one spit out and go tinkling along the road as I turned into the entrance ramp for the highway. I did get out and look for it using my Fenix PD20 single CR123 flashlight (a fantastic performing little LED unit), but to no avail. Lost the other one about 1/2-way home.

Anyway, before that I spent a few minutes using the mini sledge as a dolly with a body hammer to remove that little kink that was in the street side fender lip. Here is a pic from before where you can see the kink.

And here it is after (the kink was right in the middle of the pic where the little rust spot is on the lip).

As I mentioned previously, there are a couple of small quarter sized rust holes in the lower portion of the street side fender (one in front and one in rear), and a saw cut in the top of the curb side fender. I, being anxious about not putting too much effort in before I know that I will be able to get legally registered, wanted to slap some foil tape and paint over these and skate by for now. Karl scoffed (mockingly) and was willing to weld the relatively clean, yet highly visible saw cut. The rust holes are thin on the edges (hard to weld w/o cutting in a patch) and less blatant visually, so will get the butch tape treatment for now.

Here is that saw cut in the top of the curb side fender (steel fenders don’t make very good sawhorses!). I have shaped a piece of 1/8 thk aluminum strip to fit the underside, backing up the weld to prevent burn through.

Then I pulled it back off, sanded away the paint with the flap wheel, and put it back into place.

Here’s the first part of the weld that closed up the slot.

Then the part of the cut that didn’t go all the way thru was welded, the whole thing was sanded “good enough” with the flap wheel, and I shot it with some rattle can black paint.

Today, Wednesday, I took a half day off from work so that I could get to Wethersfield in plenty of time to get into the inspection bay before the cutoff at 2pm.

I left work and pulled into a parking lot to install these new and improved stainless steel receiver shims, now held in place by a worm drive clamp (even though they are now longer and can’t slip by the weld on the tang of the ball mount).

Next I slapped some foil tape on both sides of the rust holes in the fender and blasted them with some black paint… butch, I know. I tore the foil irregularly hoping it would camouflage, but the tape didn’t take paint too well, so it was kind of moot.

Front before paint.

Front after paint.

Rear after paint.

On the way up the left hand blinker was acting funny; sometimes flashing rapidly as if a bulb was out; then slowly; and then normally. Dagnabbit. Jumped out and checked all of the light functions again. All of the lamps where lighting, so I put it down to the TV flasher not liking the extra load from bypassing the faulty trailer relay light kit on that side. Oh well, try to stay off of the left signal as much as possible and hope it acts right during inspection.

Never having been to the big DMV offices at Wethersfield, when I arrived I pulled into the main lot (trailers to the rear) and went inside down a long hall all the way to the other end to the info desk, only to find that I needed to pull into the inspection lane on the other side of the property. Fortunately there was no line and I made it into the shed with plenty of time to spare.

Now the width across the fenders is only 79 inches. If you sight to the bulge in the tire sidewalls you can stretch it out to 79-3/4 inches. So I was pretty confident that the OEM did this so as to fall under the "80 inch and over" requirement to add the 3-light rear center marker lights. So when the inspector wrote down 80 inches wide I had to question him. Said I wouldn’t have minded and would have added the 3-light if I had thought I needed it, but since it was technically less than 80 inches I didn’t think it was required. He countered with the ole, “yeah but I’m just trying to save you from having trouble with the cops down the road. They won’t know the difference.” I kept my cool.

And now the most inane part. He asked me where I got the 2000 lb. gross weight rating that I had put on the forms. I said that it was pretty standard for these 5x8 angle iron frames and that the axle diameter supported this assumption. He said that they usually go by the tires, but because mine are 205/75-14’s (load range C at 1760 lbs. each) he couldn’t use that. He asked what I intended to haul with the trailer. (What?) I explained, in not so many words, that it was a utility trailer (duh)

and that I might haul all manner of things up to and perhaps including the gross weight rating.

He said that to establish the weight rating I needed to load the trailer in the manner that I intend to use it, take it to a certified scale, then whatever the scale ticket said would be the weight limit. What? No engineering, no safety limit; I could essentially overload the thing to whatever it would bear and the state was going to let me use that as a “safe” load limit? I apologized first, told him that I wasn’t trying to be disrespectful, but that this was an absolutely asinine policy. Not to mention that I would have to make another 3 hour round trip, and take more time off work. I was polite about it.

So next I back tracked and made a quick stop at Karl’s to borrow some big ratchet straps; a stop at Wally World to get

one of these and

a pair of these for myself (…and some jerky beef for my belly).

Then back to work to borrow a pallet tank tote for some ballast. This was the best way I could think of to: (1) make it easy to put a lot of weight on, and take it back off again; and (2) put on an amount of weight that I could calculate closely enough to be sure that I did not under load and set my GVWR too low. Here it is with the tote strapped down with its center just ahead of the axle and the garden hose going in (city water at work costs the company money, so I did this part at home).

From comparable trailer spec.’s I had been figuring that the light (empty) weight on the trailer should be about 575 lbs. The empty tote is light enough that I can shove it around quite easily, even lift one side up from the trailer to the loading dock, then slide it up and off, so it can’t weigh any more than 80 lbs… maybe less. I figured this would be margin of error and ignored it. So to be sure that I was over 2000 lbs I figured I needed to add at least 180 gallons of water (8.3 lbs/gal x 180 gal = 1494 lbs. and 575 + 1494 = 2069 lbs, so a little more margin). Since the graduated marks on the tank are somewhat crude/approximate, and the trailer was not standing level, I ran it up to about 220 gallons just to be sure (meanwhile I tucked into the house and checked out the forum while that was filling up).

Twenty three more miles one way to the nearest truck stop and certified scales (my dump is only open on Wed and Sat).

The scales are actually broken into several sections so that the truckers can get readings on each axle set, allowing them to shift their loads around and make sure that none of their axles are over the limits. I pulled the Ford up to the front section of the scales with the trailer on the second platform. Then I uncoupled the trailer so that I would get a true weight including tongue. No easy feat because the jack screw is locked up hard and won't extend or retract (although it swings into the stowed and locked down positions just fine); I had to straddle the tongue and lift with my legs to get the coupler up and the jack to swing down and lock (my back will probably remind me of this tomorrow or the next day). I forgot to take a pic on the scales. Funny thing was that the "call" button to let the attendant know you are ready to have them print out your weight is about 9 or 10 ft up on a pole; perfect for a trucker sitting in his cab, but I had to jump up to hit the button.

Trailer weight was 2680 lbs and the SUV was 3740 (more or less empty with nearly a full tank of gas). I hope they don’t give me a hassle for having two numbers on the ticket.

Since I didn't want to haul all that water all the way home, I pulled across the street from the truck stop into a commuter lot, backed up to a storm drain, opened the foot valve and let it run out before heading home.

Tomorrow I will install the 3-light bar and figure out when I will be able to take time off (we are a man down at work and the boss is a little twitchy right now).

and that I might haul all manner of things up to and perhaps including the gross weight rating.

and that I might haul all manner of things up to and perhaps including the gross weight rating.