... Thinking a frame like that cut out of 1/4” plywood , 2" of foam over it and some canvas and call it a day ...

... Thinking a frame like that cut out of 1/4” plywood , 2" of foam over it and some canvas and call it a day ...  Something like that (hybrid) would make most everyone Happy ...

Something like that (hybrid) would make most everyone Happy ...

Moderator: eaglesdare

... Thinking a frame like that cut out of 1/4” plywood , 2" of foam over it and some canvas and call it a day ...

... Thinking a frame like that cut out of 1/4” plywood , 2" of foam over it and some canvas and call it a day ...  Something like that (hybrid) would make most everyone Happy ...

Something like that (hybrid) would make most everyone Happy ...

ghcoe wrote:My hatch is actually designed for leaks. If water should get past the gasket it will drip onto the sub-roof which has a gutter built into it to carry the water to the sub-sides of the galley and then out the bottom.

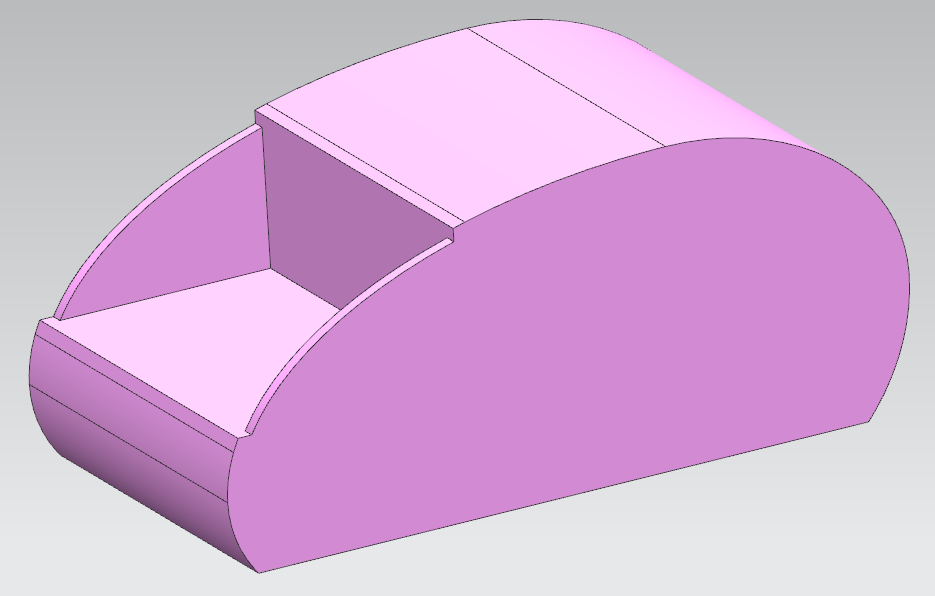

mikeschn wrote:Just for fun, I drew up a foamie body based on a larger Nano Cub

Mike...

... George's drip channel idea is brilliant .... the water IS going to get in .. and it just needs a quick path to get Out ...

... George's drip channel idea is brilliant .... the water IS going to get in .. and it just needs a quick path to get Out ...

Industrial stuff ...

Industrial stuff ...  The little foam bits just starting to disappear in the yard ...

The little foam bits just starting to disappear in the yard ...  And with the Math in the kerfing thread , it’s entirely possible to get the kerfs perfectly placed and sized to close completely on the inside curve , making a Nice finished look ...

And with the Math in the kerfing thread , it’s entirely possible to get the kerfs perfectly placed and sized to close completely on the inside curve , making a Nice finished look ...  Lots of Prior Planning ...

Lots of Prior Planning ...

So True !!!

So True !!!

mikeschn wrote:Just for fun, I drew up a foamie body based on a larger Nano Cub.

But I need a material that's waterproof, that I can drive screws into, for spars, and other supports... any ideas?

Mike...

sorta’ like buying the bird before you build the nest ....

sorta’ like buying the bird before you build the nest ....

Users browsing this forum: jgmahoney and 12 guests