So, this project

6.5X13 all aluminum trailer

As to be light...shooting for 1000lbs

will be a almost standy 5.5 feet inside height

no water tank, no electricity system, we kept it simple, normal rechargeable pucklight battery

no AC...i live in canada!!!

Winter proof...well insulated, we do lots of winter camping (we connect to 110v when in cold weather so ceramic heater it is!)

queen size bed for parents, Bunk bed for 2 kids

Enough place for doggy to sleep on his own little bed on the floor

some storage...lots of it!

Kitchen galley at the back....because cook happen OUTSIDE!!! even in winter

need to be pulled behind normal 4 cylinder 150-170hp vehicle...

i found a awesome place to buy all my aluminum, they have everything, i just have to walk in there warehouse, pick peices..cut them if needed and they sell so cheap.

Time to learn new skills.... i want to weld aluminum

Eastwood 180 mig welder 539$

argon 60cf tank 100$

and lots of extra tips and a brass bruss

it was time to lay down the chassis with peice that i cut using a mitre saw

doggie is ready for a trip.....she is right were the bunk bed will be!!!

my tongue design....should be more than enough...even a overkill for a 1000lbs trailer....even if i go above the goal....the middle member is 3x3 x 3/16 and that should be enough for 2000lbs trailer.... so with 2 cross member...i went beyhond what is needed. I copied the design of a few utility trailer all aluminum rated for 2999 lbs...

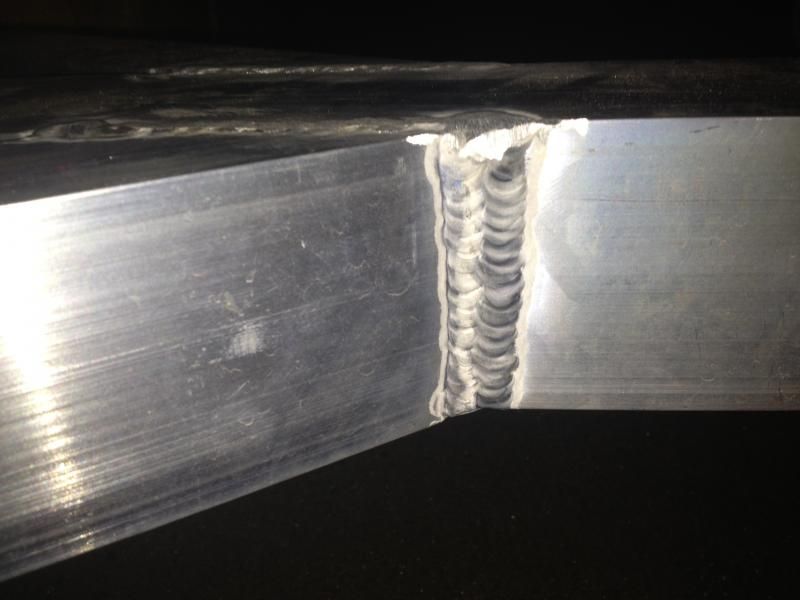

and the welding start.... well, i done 1 week of practice on so many little scrap piece....and realise quickly that it will take awhile to learn to weld aluminum properly. i had a professional that helped me with some of the important structural weld and guided me with feeding and power setting. it s not always pretty but it s been a lot of fun....

started building the front dinnet/queen bed....direct into the frame. as i went relatively light with tubing, i want to make sure everything is connected and strong.

lets weld!!!

after week 2..... thats where i m at... both side of the dinnet is done...now it will be time to build the frame on top of the trailer. Axle or Axles..... will come later in the game...i need to make my mind of a single or tiny tandem axle design...most likely torsion

my questions now....

Tandem torsion axle...would it be as simple as welding 2 torsion axle mount to the side members or does special strening of the frame is needed for tandem???

Should i do my own door?? that s something that ''scare me'' i have no clue how?

how to bend aluminum tubing at home when you dont have any special tools? can i just make a wood shape and bend the aluminum tube against it? i need to make the front shape of the trailer and would prefer to avoid doing squared/welded shape with simply bending 1x1 tubing....

how to make the floor? plywood? simple aluminum sheet? how thick would i need???