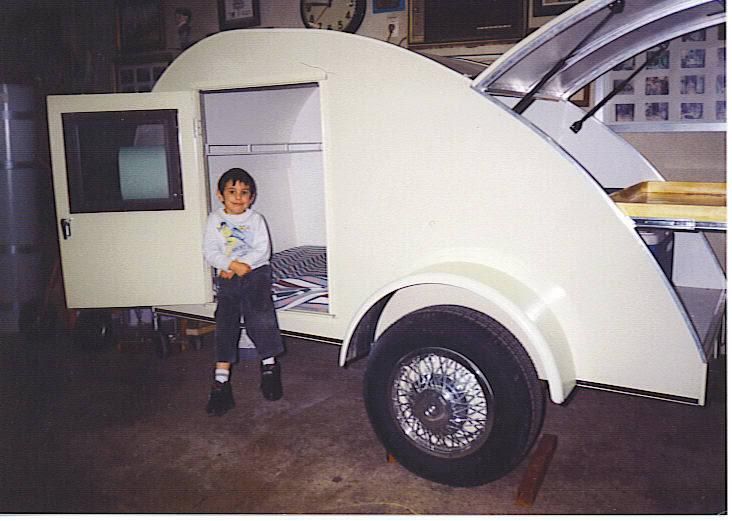

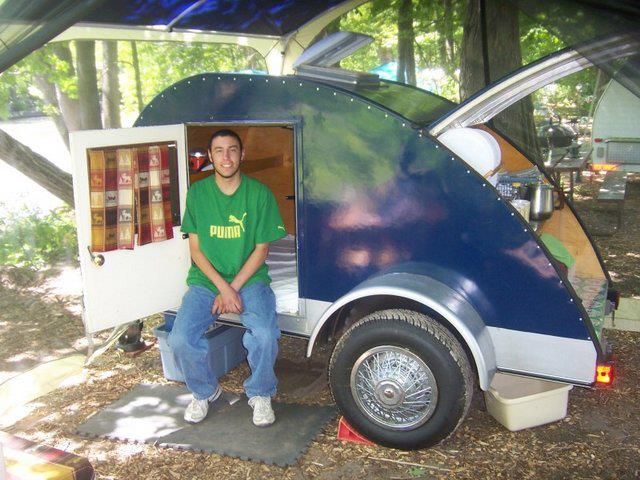

Father/Son Tear Build

47 posts

• Page 1 of 4 • 1, 2, 3, 4

Father/Son Tear Build

Since my build is officially underway, I figured I would go ahead and get my build thread started too. Otherwise, things can get ahead of themselves! We are starting with a HF 4x8 1195lb frame, that will be getting a few mods. Most importantly, it will be fully welded AND bolted together. Tonight we got the front half of the trailer assembled and squared up. (kinda) Now for my first of many, many questions: It is out of square by about 1/32" on the diagonal. Do you think this is close enough? With all the flex in the thing, I can't imagine it needs to be much closer. If you've found it to be a problem, let me know and I'll loosen it up and try again.

-

jgrote - Teardrop Advisor

- Posts: 84

- Joined: Fri Oct 18, 2013 5:32 pm

- Location: Denver(ish)

Re: Father/Son Tear Build

To be honest I can't tell if you are kidding in a bragging sort of way, or if you are dead serious!

Either way 1/32 inch is plenty good enough for the frame.

I try to keep everything as accurate as I can, sometimes spending more time to do so, but for most things even 1/16 is plenty good enough.

The only things that might need to be held to tighter tolerances are glue joints on wooden structure, and for finish work like cabinets and trim.

Really it comes down to how important the dimensional accuracy is to the strength integrity (will the joint fit well enough for the glue and fasteners to achieve full strength?); the on going build requirements (will a bad dimension create a domino effect of poor fits or complex adaptations to get good fits?); and aesthetics (can you stand to look at it and would you be proud to show it off?)

Strength of your frame won't be affected by 1/32 tolerance. Building up from the frame you will have plenty of opportunity to maintain this or tighter tolerance (if required), and if you stand back a little you will never be able to see 1/32 out on your frame, so it must be okay visually.

I'd say you re good to go.

p.s. If you had included a pic I would have said, "it looks good from my house".

Either way 1/32 inch is plenty good enough for the frame.

I try to keep everything as accurate as I can, sometimes spending more time to do so, but for most things even 1/16 is plenty good enough.

The only things that might need to be held to tighter tolerances are glue joints on wooden structure, and for finish work like cabinets and trim.

Really it comes down to how important the dimensional accuracy is to the strength integrity (will the joint fit well enough for the glue and fasteners to achieve full strength?); the on going build requirements (will a bad dimension create a domino effect of poor fits or complex adaptations to get good fits?); and aesthetics (can you stand to look at it and would you be proud to show it off?)

Strength of your frame won't be affected by 1/32 tolerance. Building up from the frame you will have plenty of opportunity to maintain this or tighter tolerance (if required), and if you stand back a little you will never be able to see 1/32 out on your frame, so it must be okay visually.

I'd say you re good to go.

p.s. If you had included a pic I would have said, "it looks good from my house".

KC

My Build: The Poet Creek Express Hybrid Foamie

Poet Creek Or Bust

Engineering the TLAR way - "That Looks About Right"

TnTTT ORIGINAL 200A LANTERN CLUB = "The 200A Gang"

Green Lantern Corpsmen

My Build: The Poet Creek Express Hybrid Foamie

Poet Creek Or Bust

Engineering the TLAR way - "That Looks About Right"

TnTTT ORIGINAL 200A LANTERN CLUB = "The 200A Gang"

Green Lantern Corpsmen

-

KCStudly - Donating Member

- Posts: 9640

- Images: 8169

- Joined: Mon Feb 06, 2012 10:18 pm

- Location: Southeastern CT, USA

After the trailer is built, but before the start of the camper part, it will get a generous coat of bedliner. It's fairly cheap and can be painted on top of just about anything.

After the trailer is built, but before the start of the camper part, it will get a generous coat of bedliner. It's fairly cheap and can be painted on top of just about anything.