Jeff

That is too cool.

Tom

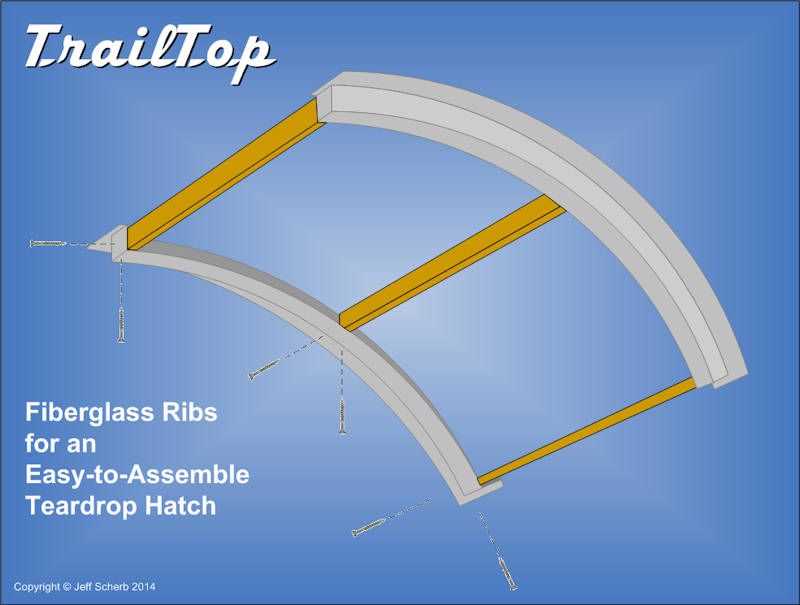

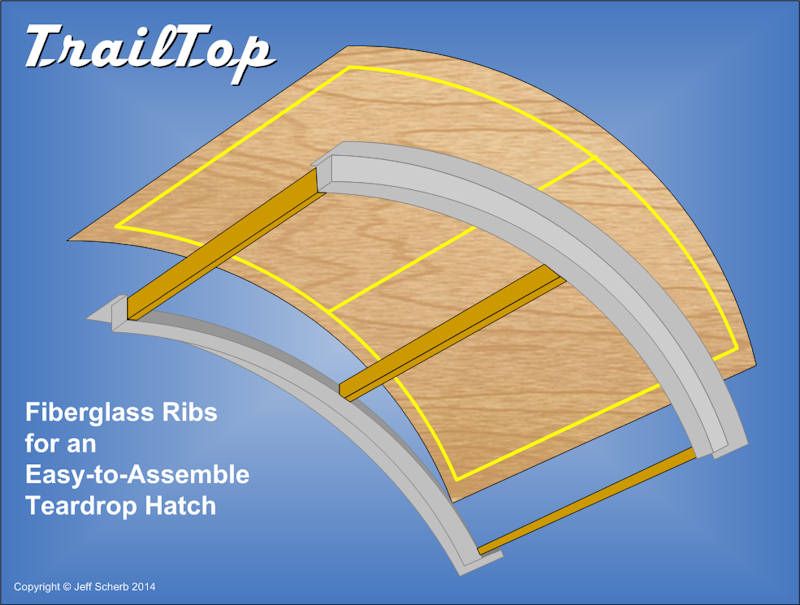

"TrailTop" modular trailer building components

Re: "TrailTop" modular trailer building components

Coffee is like liquid hugs, it warms you from the inside out

- Hardryder56

- Teardrop Advisor

- Posts: 92

- Joined: Mon Nov 25, 2013 5:04 pm

- Location: Lake Conroe, TEXAS

Re: "TrailTop" modular trailer building components

What a great concept. If you had some traditional Tear Drop designs and a way to connect them to a platform on a frame that would take a ton of the guess work out of doing the basic build design. The hard part is the galley hatch so if you had a way of providing the hatch frame itself and the frame work around the hatch with hinges and locking mechanism that would be the ultimate in accomplishment. The rest of the construction should be easy. The molds could have inner and outer skin recesses so that insulation could be in between, a place to mount fenders and perhaps a frame for the door. These could be sold as inexpensive kits with most of the materials purchase locally. Modern building concepts and the traditional design, the possibilities are endless!

The eleventh commandment: Ye that snoozeth loozeth. Selling real estate in ALL of Jefferson State (Northern California and Southern Oregon)

My Build http://www.tnttt.com/viewtopic.php?f=21&t=49746

My Build http://www.tnttt.com/viewtopic.php?f=21&t=49746

-

Rhino Ray - Silver Donating Member

- Posts: 363

- Images: 60

- Joined: Sun Aug 28, 2011 6:02 pm

- Location: Roseburg, OR

...!

...!