mikerueve wrote:I've been watching all of the posts and additions you've done to the thread and I can tell you that if these parts had been available to me, I would have jumped all over them instead of having my own built. Even with my LIMITED skills, I think I could have built a trailer with all of the angles covered. The hatch idea is the thing that would have sealed the deal for me.

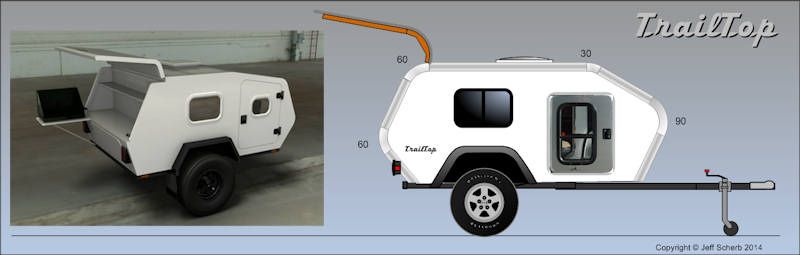

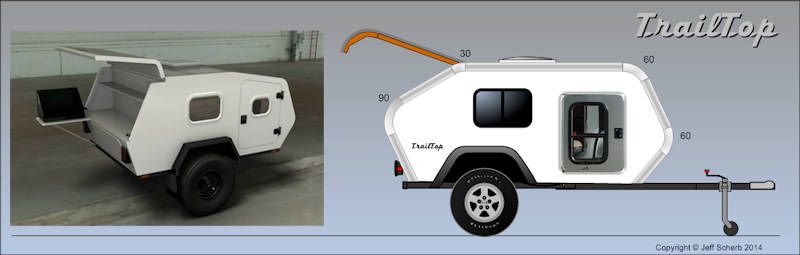

Thanks for the comments. My goal is exactly that - people who might be intimidated by the thought of building a camper, especially a curvy teardrop, from scratch, hopefully will look at the TrailTop components and think "I could do that". I'm pretty confident the hatch design I recently posted will also rate an "I can do that" too, but when I get to that point in the project I'll post the assembly steps for the hatch and you guys can tell me if it's easy enough.

mikerueve wrote:One idea I did have was concerning the appearance of the pre-molded pieces after the build. I've had some dealings with modern print shops and what they can do as far as printing vinyl. I think it would be really neat to have them print a contrasting wood grain in sheets of vinyl that could be used to "wrap" the fiberglass pieces. I've done quite a lot with the material on various cars with just my hands and a blow dryer and the results you get can rival any paint job I've ever seen. The only issue is that it will fade some in the sun.

That's a really interesting idea, I hadn't thought of that before.

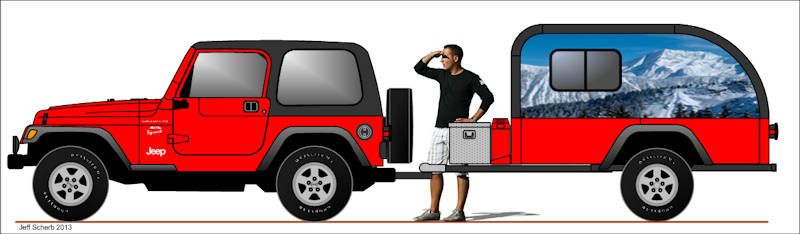

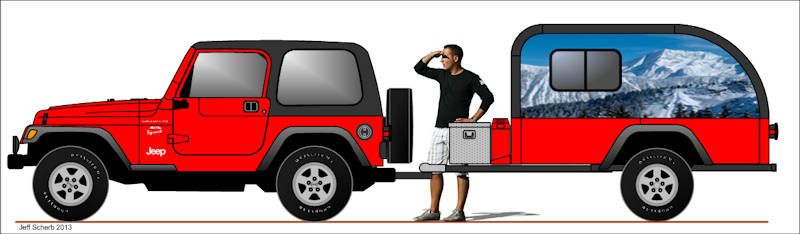

I have thought about wraps for the exterior, the concept below was in the first post of this thread - it also had the TrailTop parts painted to match the Jeep's hardtop color. I even stopped by my favorite local decal shop and asked them how much they would charge to do a set like the ones below, just in case I decided to use them on my prototype...

Fiberglass takes paint really well, so when I did the animation below I showed the TrailTop parts painted in red to match the Harbor Freight frame:

It would be possible to mold the parts in gelcoat other than white; although that would cost a bit more depending on the volume of that color that could be sold because most fiberglass shops buy their gelcoat in fairly large quantities. Most shops have white and black gelcoat on hand, so there's typically no extra cost for either of those.

And now that you made me think of it, I'll have to check and see how much black gelcoat I have on hand... since I'm building the prototype on top of this black Jeep-tub trailer kit, maybe I should mold the first set of TrailTop parts in black.. hmmmmm....

.

.

...

...  ...!

...!