...!

...!grant whipp wrote:Looking great, Jeff ......!

The baggage door is cool feature, too! As always ...

CHEERS!

Hardryder56 wrote:Jeff, looking great.

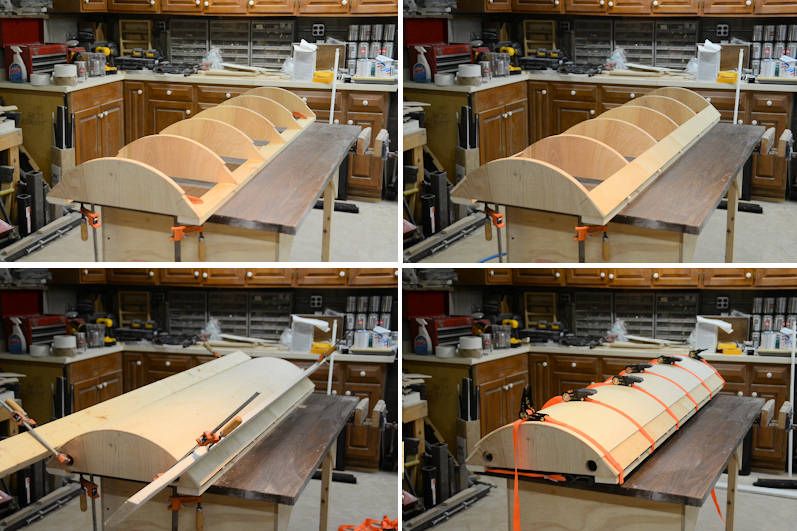

I can see 1 inch (or more) foam laminated to the inside of the plywood skin for insulation with any gaps in the corners filled with spray in foam. This would make a very rigid and air tight structure. Looking forward to hearing if a company picks up your idea and runs with it.

Tom

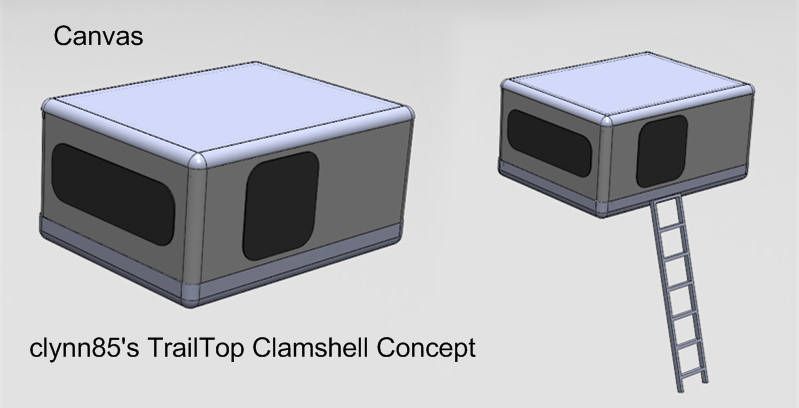

wagondude wrote:I really like how this concept is shaping up.

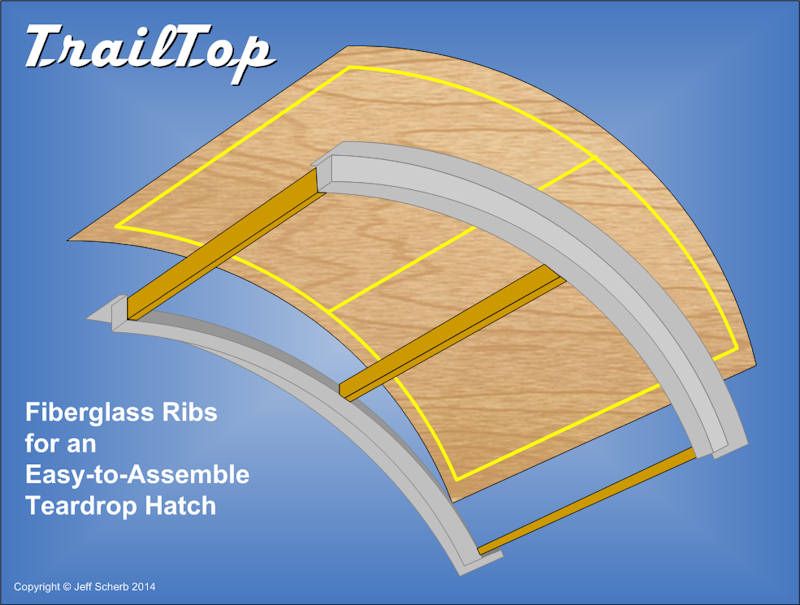

wagondude wrote:Don't forget, folks, These parts could also help with construction of a bread loaf type standy as well. Someone comfortable working with 'glass could even use them to put together a canned ham. But that would be a bunch of reworking of the basic components. The bread loaf could easily be done with just the currently proposed parts.

.

.

.

.

Rhino Ray wrote:I learned a great lesson from Grant. The hinge on the galley hatch is a bit tricky. To create a smooth line from the roof on down the galley lid the frame has to be adjusted the thickness of the lid and seal to receive it if it were to be water tight. Unless you have another way to do it a flat surface still has to have a seal to keep the rain out. Check with Grant, the most important cross member is the one that attaches the hatch. Good luck!

Users browsing this forum: No registered users and 8 guests