Father-Daughter Build 2013-14

Re: Father-Daughter Build 2013-14

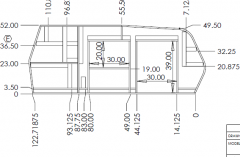

One of the deciding factors in the width of the door is the head of the bed in the rear or in the front. Bed is the reverse of most so that once you sit on the edge of the bed you schooch backward and the legs follow. The revers is more difficult and you need enough room to turn. Ours are 30" and not too large.

-

Shadow Catcher - Donating Member

- Posts: 6008

- Images: 234

- Joined: Sat Apr 11, 2009 8:26 pm

- Location: Metamora, OH

Re: Father-Daughter Build 2013-14

Tom- Excellent drawing and your words made sense! I see what you mean. When I look at KC's build I think the offset for the door was created by layering an 1/8" border around the door, from what I can tell from his pics. KC can correct me if I am wrong.

Jon- I have already spoken to Grant and am going to go with one of the two you mentioned in your post. I may just need him to talk me through how much of everything I will need based on my dimensions.

I know all the planning will pay off and the help you are all giving is amazing! Drawings and pictures are SUPER! Hopefully tomorrow will be a snow day and I can do more planning and research! (6-15 inches expected folks)

Jon- I have already spoken to Grant and am going to go with one of the two you mentioned in your post. I may just need him to talk me through how much of everything I will need based on my dimensions.

I know all the planning will pay off and the help you are all giving is amazing! Drawings and pictures are SUPER! Hopefully tomorrow will be a snow day and I can do more planning and research! (6-15 inches expected folks)

-

lfrazer98 - Teardrop Master

- Posts: 204

- Images: 217

- Joined: Tue Sep 17, 2013 6:25 pm

- Location: New York

But, we did work every day from about 9am until dinner. I was astonished how long everything took to measure, cut, sand, stain and poly! We also went shopping every day, because we never seemed to have exactly what we needed. I was uncertain about the wood and stain after making the face frames, but I am happy to report that my drawer fronts and cabinet fronts stained well! There was also a piece of maple with beautiful ripple marks on it. I wasn't certain how it was going to stain, but it made almost a zebra like pattern. I like it! Here are the photos from yesterday. Got the staining done and just need to poly.

But, we did work every day from about 9am until dinner. I was astonished how long everything took to measure, cut, sand, stain and poly! We also went shopping every day, because we never seemed to have exactly what we needed. I was uncertain about the wood and stain after making the face frames, but I am happy to report that my drawer fronts and cabinet fronts stained well! There was also a piece of maple with beautiful ripple marks on it. I wasn't certain how it was going to stain, but it made almost a zebra like pattern. I like it! Here are the photos from yesterday. Got the staining done and just need to poly.