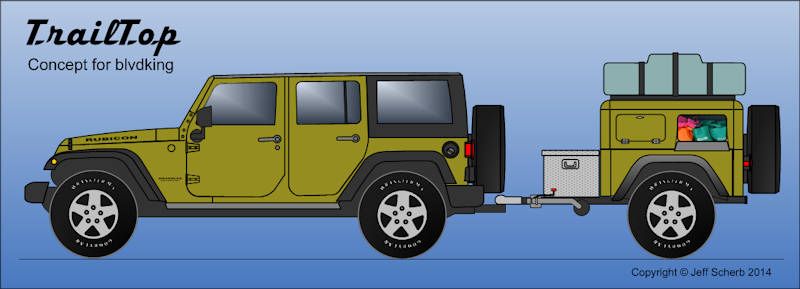

I've been thinking for years of basically doing what your left photo shows but on top of a simple utility trailer. My design (in my brain) had an advantage - there are 4 corner supports with a length of 3.5 ft. Theses supports consist of a square tube in a square tube thereby allowing me to raise the roof and pin it in its elevated position. My thoughts were to KEEP IT SIMPLE - If the roof weight is low enough the user could supply the power to raise and lower. While I see that you can't have long corner supports, I'm throwing out my idea only to help spark other ideas.

I like the idea of using your components to build a roof for someone's utility trailer. They could then use a pattern to sew the walls/windows/doors/screens and attach this unit to a purchased utility trailer and voila - instant ultralight tent trailer.

Rather than canvas, please investigate some of the lighter materials. It seems that you want that industrial sewing machine and I can't argue with tool lust - we all have it. But ripstop nylon and silnylon might perform to your expectations at a fraction of the weight; remember, it is on the rooftop and must be lifted. I make almost all of my own backpacking gear. I am on about year 12 for my first silnylon tarp. No signs of degradation. I just finished 2 ultralight hammocks and am currently making hammock underquilts and tarps. I love my thread injector (sewing machine). We manly types must have a manly name for our tools

.

.

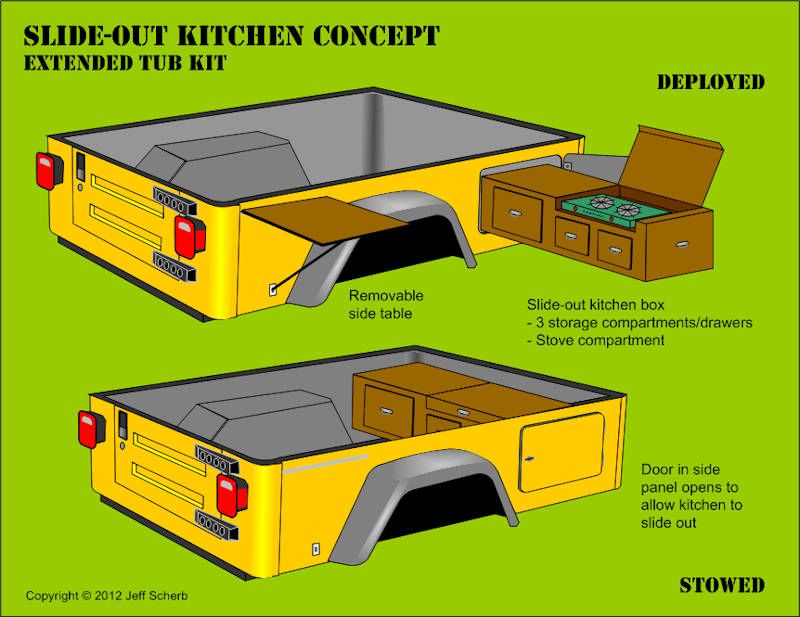

... I agree with your decision to go with the tailgate ... without a side entry door, you'll need to access the inside from the rear, and climbing over anything in the galley area would just be cumbersome and inconvenient. One thing you could consider (if you have any plans to make this function like a teardrop) would be to make the bed fold like a futon, kind of a couch across the front, with some kitchen-like cabinets in the rear corners to compliment whatever could go on the tailgate.

... I agree with your decision to go with the tailgate ... without a side entry door, you'll need to access the inside from the rear, and climbing over anything in the galley area would just be cumbersome and inconvenient. One thing you could consider (if you have any plans to make this function like a teardrop) would be to make the bed fold like a futon, kind of a couch across the front, with some kitchen-like cabinets in the rear corners to compliment whatever could go on the tailgate. ...!

...!