djb_rh wrote:Just curious, but what's the preferred method of cutting the fiberglass parts?

Fiberglass is best cut with abrasives. You can use an ordinary saw, but the impacts of the teeth can cause microscopic cracks that can spread over time. A hacksaw blade works better than a woodcutting saw, as does a fine metal-cutting blade in a jigsaw. But I pretty much always use abrasive cutting tools. Here's my arsenal of cutting and trimming tools:

Right to left:

- 4 1/2" angle grinder with a 1/16" thick abrasive cutting disk. For fast cutting of large, more-or-less straight edges. I use this tool more than any other for cutting fiberglass.

- Die grinder with a 1.5" diamond cutting disk. For more intricate cuts, more accuracy. I haven't used this on the TrailTop parts because all of the cuts required in these parts are straight. I use this for trimming other parts, for example the wheel arch curves of fiberglass fenders like those on the CJ Grille Kit.

- Angle die grinder with Rolok attachment for sanding disks. For fine adjusting of the trimmed cuts. I've been using a 50-grit disk in this to fine trim the tabs on the on the ends of the TrailTop where they join together.

- 6" D/A sander. For quick adjustment of larger cuts. Haven't used this on the TrailTop project.

- In the back: a 30" long board sander. To ensure long straight cuts are really straight. I'll probably use it along the bottom edge of the TrailTop parts for the hard cover proof-of-concept I'm working on right now.

If you didn't own any of the above you could do just fine with a hacksaw, a sanding disk in an electric drill for trimming, and a couple of files for fine trimming.

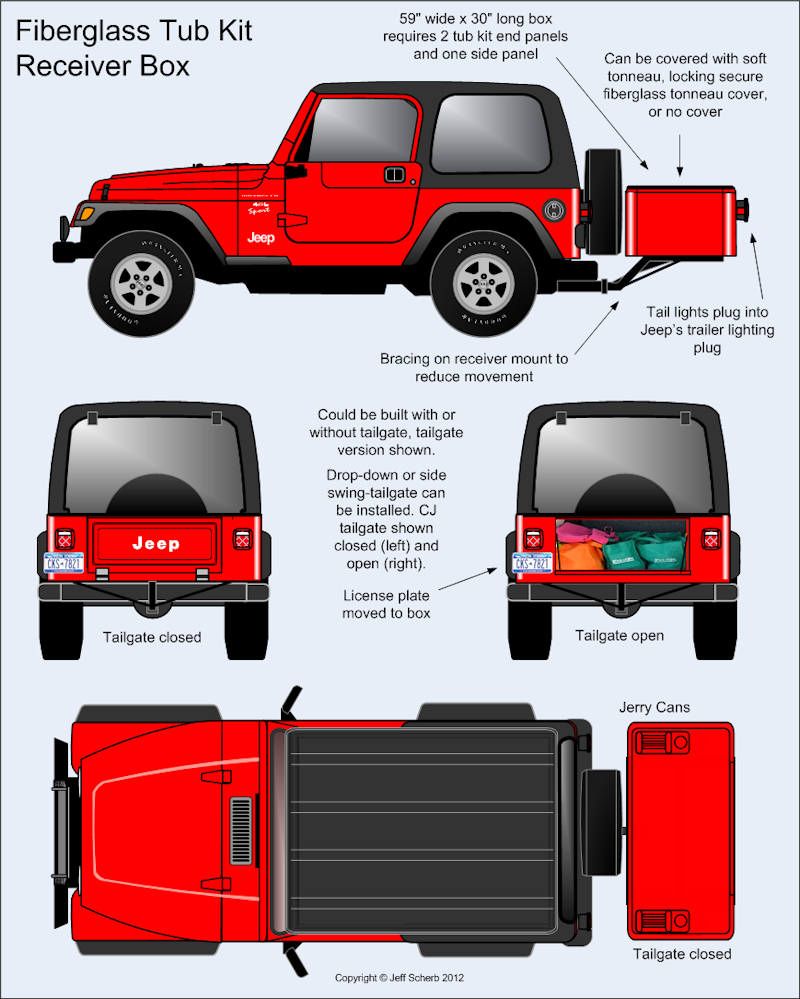

djb_rh wrote:And thanks for the hitch box pics. That's a neat idea, too, for the Jeep crowd.

Or for a tongue box on a trailer.

djb_rh wrote:

Just waiting for someone to take my money and ship me TrailTop parts (and CJ front body parts, but...).

--Donnie

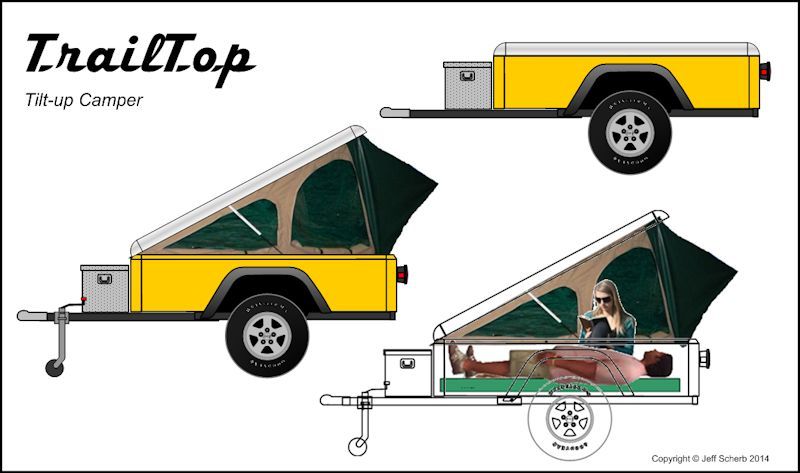

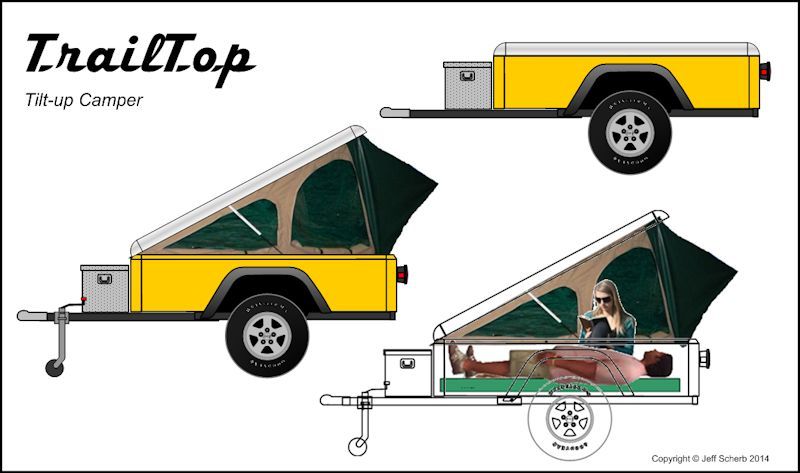

Could happen with the TrailTop parts, haven't decided yet if they should be commercialized.

.

.

Don't have a clue what you might have up your sleeve for your next project. Sure hope someone picks up and markets your DIY system soon.

Don't have a clue what you might have up your sleeve for your next project. Sure hope someone picks up and markets your DIY system soon.