Just finished the whole thread. Awesome work :-)

My vote would be a custom replacement for the old truck cap on my camper.

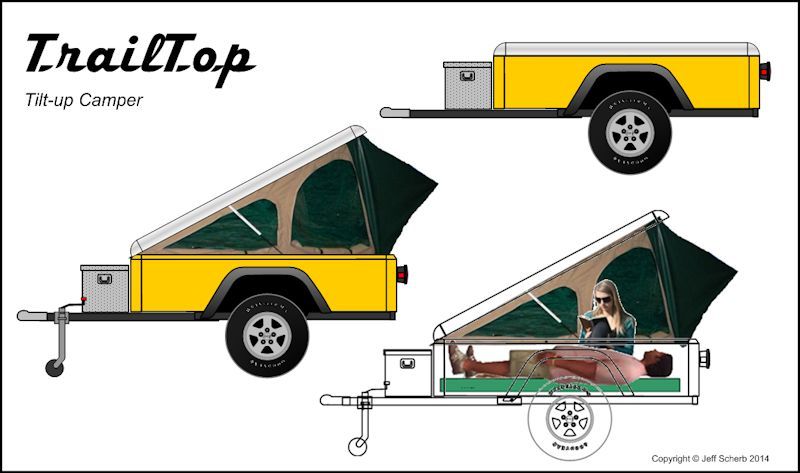

"TrailTop" modular trailer building components

Re: "TrailTop" modular trailer building components

- Attachments

-

- uploadfromtaptalk1400616602113.jpg (182.92 KiB) Viewed 2350 times

Pete Olson

Newburgh, IN

"Patrol Box" camper build thread http://tnttt.com/viewtopic.php?f=50&t=55583

It's only dumb if it doesn't work.

Newburgh, IN

"Patrol Box" camper build thread http://tnttt.com/viewtopic.php?f=50&t=55583

It's only dumb if it doesn't work.

-

pjo129 - Teardrop Master

- Posts: 264

- Images: 73

- Joined: Wed Aug 31, 2011 9:59 am

- Location: Newburgh/Evansville, Indiana

Re: "TrailTop" modular trailer building components

I'm planning the strut installation to support the tilt-up feature of the cover. The cover will be hinged on the front, and will have two struts to support it when open.

I'll need struts with about a 10" difference between the open and closed length, and about 50 lbs. force each, so I searched the U-Pull junkyard for hood support struts because they should have about the right specs. I found a pair from a Kia Sorrento that look like they'll be just fine. Here's a mockup with the struts:

The height of the high end when open will be about 42", which gives about 5' from the tub floor to the bottom of the cover at the peak. Plenty of room to turn the hard cover into a camper...

I'll need struts with about a 10" difference between the open and closed length, and about 50 lbs. force each, so I searched the U-Pull junkyard for hood support struts because they should have about the right specs. I found a pair from a Kia Sorrento that look like they'll be just fine. Here's a mockup with the struts:

The height of the high end when open will be about 42", which gives about 5' from the tub floor to the bottom of the cover at the peak. Plenty of room to turn the hard cover into a camper...

- jscherb

- The 300 Club

- Posts: 388

- Joined: Sat Dec 24, 2011 8:27 am

- Location: Elmira, NY