I got a bunch of little stuff done today:

-Cut a space for the wires going from the trailer to the hatch, I'd drilled them through the crossmember too high and they would have interfered with the hatch closing.

-Sanded and filled the hatch again

-Sanded the walls at the wheel well curves and the door frames

-Made the two door cut-outs into side tables, including sanding, round-over'ing the edges and fitting the table rails to them. I had two 36x26" cut outs to work with, so one has the rail on the long edge and one on the short edge. I had hoped to prime them and the galley interior this evening, but the router revealed a 1"-long void in the plywood that I wanted to fill before priming. The long edge railed table will go low on the driver's side and get two folding legs underneath it (adjustable in 1/2" increments) for our cooler or other items that do not fit nicely in the galley.

The short edge table will go on the passenger side and I'm a little conflicted about it, the one leg I bought for testing only goes to about 32" high, I would need ~37" to make it equal to my countertop. I could always bring along a base of some sort for it, or I could put it at 30" and have it the same height as a normal kitchen table (vs 36" for countertop height). I set up one of our camping chairs at the kitchen table and tried to eat from it, our chairs end up way too low to the ground to be comfortable/natural.

At what height do most people put their side tables?

I had to give a neighbor a tour of the tear, he caught me outside working on it and said his family had been taking guesses at what it was for the last few months. They'd never suspected it was a camper.

The wiring notch, a Multimax made it super easy, but not as square as I wanted.

- 20140809 wiring notch small.jpg (125.93 KiB) Viewed 2005 times

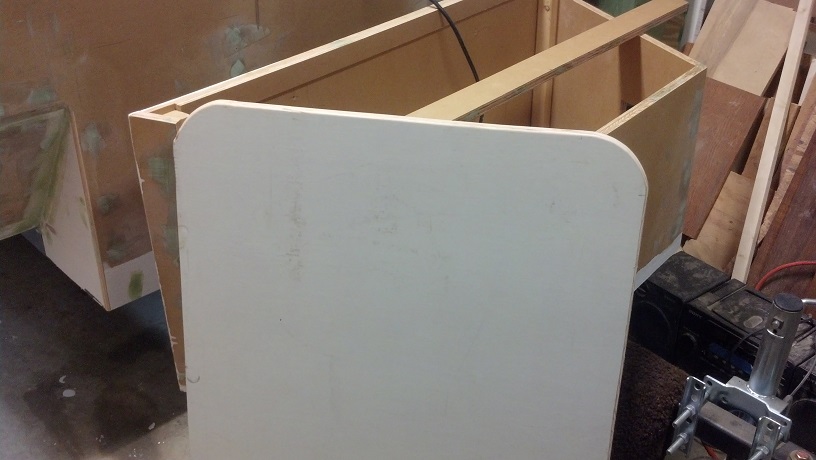

One of the side tables after routing:

- 20140809 side table small.jpg (95.85 KiB) Viewed 2005 times

Oh well, I'm not putting the plates on the wall for the bunk track either, so that'll just get added on at a later date.

Oh well, I'm not putting the plates on the wall for the bunk track either, so that'll just get added on at a later date. ), but we had some time for a few Weekender projects.

), but we had some time for a few Weekender projects.  )

)

At what height do most people put their side tables?

At what height do most people put their side tables?