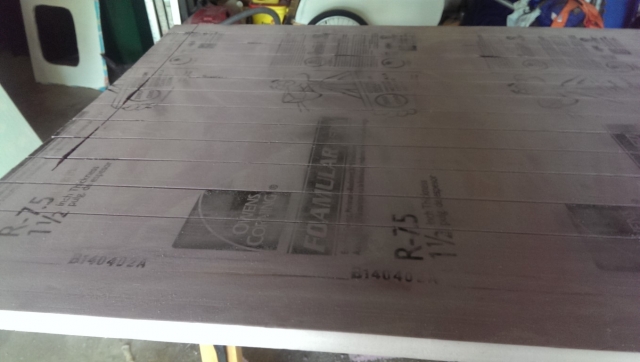

So I started on my hatch the other night and kerfed the foam. The quick will notice I cut one kerf the wrong direction

. At least I noticed before I cut more than one?

I was then stumped and stopped because I was out of Gorilla Glue, and I was going to lose my whole weekend to travel. Which it turns out was just as well because it made me think about things.

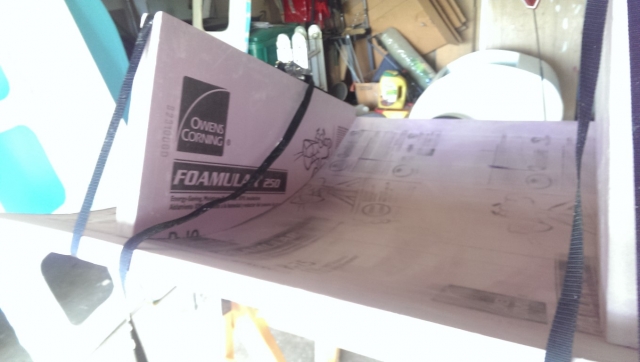

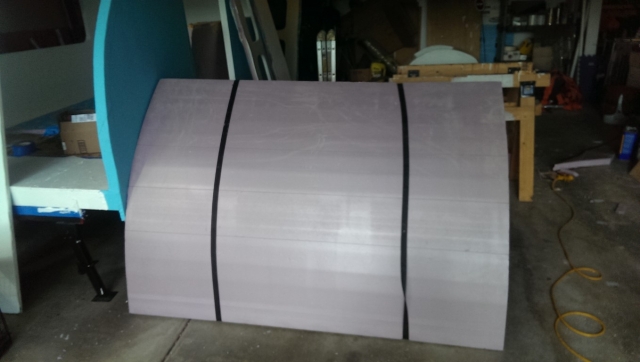

I had been planning to mask and tarp off all the finished bits of the trailer and then shape the hatch to fit the curves while trying not to get glue on anything important. Which as we all know is a joy and a treat with GG. Then while sitting on the tarmac waiting to head out of town I had a good idea. Why not make some fake hatch curves out of offcuts of foam. Then do my glueup on them away from the trailer! So given one piece of my roof foam that I had cut off the remaining 30" of width I managed to get two curves cut! So I still have some big chunks of foam left.

I then shaped everything around the fake hatch curves with some ratchet straps. When I do this for real with glue I'll be sure to put some cardboard where the straps run over the edges of the hatch.

Now I have to decide if I am going to do my hot wire inletting and installation of the backer blocks for things like the hinge and the latches and the prop rods before or after I glue up the curve. Also I have to decide on inside or outside the hatch for each of them.

My thoughts are hinge reinforcer bar on the outside to match the roof.

Latch backer blocks on the inside so they pull THROUGH the foam not just one layer of canvas.

The prop rods.. they vex me.. inside? outside? there will be forces in each direction. Although I think the gravity effects of my foam lid are not significant , so I am thinking outside so the prop rod when it pushes on the block it COULD push through the back if the gorilla glue and canvas fail, but that way if the wind grabs the hatch it will have the foam and the fabric and the glue holding it all in.

Perhaps I should make some pictures of this.

. At least I noticed before I cut more than one?

. At least I noticed before I cut more than one?

don't tell anyone), and my lower hatch spar is higher up on the profile than I expected when I made an adjustment in my rib placement to allow for canvas thickness. The plans are just a guide. Stuff still has to be made to fit, and the further along in the plan, the more stuff has to be "fit to suit".

don't tell anyone), and my lower hatch spar is higher up on the profile than I expected when I made an adjustment in my rib placement to allow for canvas thickness. The plans are just a guide. Stuff still has to be made to fit, and the further along in the plan, the more stuff has to be "fit to suit".