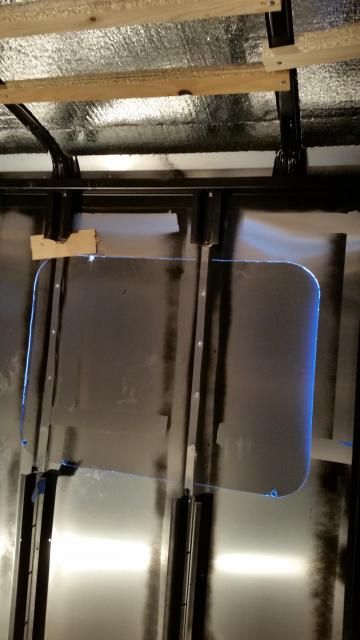

Windows arrived and were exactly as described in the ebay ad. I reviewed the window post yesterday and have one followup question. My windows are new, and have a thick piece of foam on the inside of the outside trim piece. It appears that this is intended for a good seal, but in the window post, I see folks are using some type of third party sealant. So, do I need to:

1. peal this foam off and replace with sealing material noted in the widows post

2. leave the foam in place and use additional sealing material

3. just use the foam that is on the windows.

First window installation, so want to do it right the first time.

Thanks

Professors 7x14 Toy Hauler

Re: Professors 7x14 Toy Hauler

It's black foam rubber, right?

It's black foam rubber, right?It works. It compresses. But it's open cell foam rubber. It's gonna soak up a little water on the edge, grow green moss or get a little UV damage, so just paint it white (enamel) after it's compressed in place.

The alternative is butyl tape, a ribbon of putty that lasts for 20 years before it gets brittle. Pretty much impervious to UV and nothing grows on it.

RV shops generally use double layers of the butyl tape. You get a good bed for extra protection against water entry and out-of-plane irregularities that way. Some of it squeezes out on the first hot day, so you have to trim the edge of your window with a razor knife to remove the excess. (But wait till the sun goes down, cuz it strings out bad, making a mess, when it's hot and you try to pull it off.) Tighten the screws on the interior trim ring after the first hot day.

Using both gains nothing. You just get the minor downside issues of both. NG.

Your call.

My goal...

_____________________________________________

...is to live in a trailer.

_____________________________________________

...is to live in a trailer.

-

Prem - Gold Donating Member

- Posts: 3222

- Images: 144

- Joined: Thu Aug 21, 2008 11:25 am

- Location: State of Jefferson (Oregon side)

Yeah. You rock.

Yeah. You rock. Dude, you should experience cutting the monster hole for an RV door!

Dude, you should experience cutting the monster hole for an RV door!