I was a bit anxious to get back to working on the TD. So, hastily, I unwrapped the long tube of parts I got from Grant, and started to cut away. First challenge was that I used a left handed cutting tool that bent the aluminum up one way and down the other. I had to try to straighten out the metal, and this started off looking pretty bad.

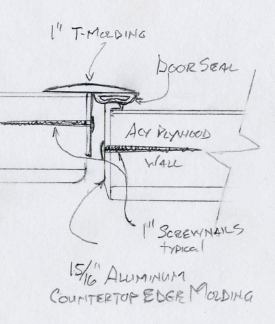

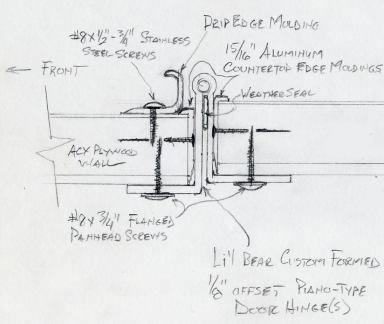

As I cut, I installed the pieces of edge molding, and T-molding, as well as the offset door hinge.

BIG MISTAKE!

I should have looked over my supplies, and decided on the best piece to use, instead of just grabbing the first one I could.

I should have cut the pieces, then dry fit them. But I secured the pieces to the door as I cut them. It cause a bit of anxiety.

The topped curved piece was the last piece I cut , shaped and fitted. All the other pieces I cut, applied clear sealant and adhesive and tacked each side with just three short twist nails. I did, at least, make sure that the overlaps at each end allowed for any possibly water to go over the joint, rather than allow it to accept and hold any potential water.

But the top bent piece was a bear. I'm not really sure how to do this right.

I tacked two short twist nails at the end to hold it in place, then as I bent it, I tried to tack additional nails closer together. The only problem was when I mis-hit the nail, I would ding the aluminum t-molding and nick it. I also decided to try using a few pan head screws to see if that might hold better than the nails, which I didn't trust on holding as I feared that the force of the bend might pop out the nails. Worst case scenario is that if the screws are too big for the closing of the door, I'll take them out, and fill with caulk to keep the water from penetrating.

I found that when bending the t-molding that it tended to twist as well, and it was tough keeping the face of the molding on the flat part of the door. I had to take out the nails a few times and re-position it, using clamps to secure the t-molding so it was flush with the front of the door.

I'm a little concerned that the combination of this twisting and the nicking of the t-molding may compromise the integrity of the watertight seal when the door is closed. But I attribute my fear to inexperience, and hope that it will prove to be ok.

The top of the door looks really rough and not well done at all. The second door should be much better.

One note here, is that when I was tacking the nails into the t-molding, I was smart in that I pre-drilled holes for the nails to go into. The one nail I did not do that for caused my set up to almost explode. All the tools and nails I had sitting on top went everywhere.

I'm a little upset that these dings look bad.

I was able to apply some 50 year clear caulk to the edges to seal these. We'll see how this holds up.

- QMKbWqWe9YxkpPwnnfk0a5dNw7Q1D1nava3xQJJgs0U=w821-h809-no.jpg (71.62 KiB) Viewed 1542 times

Here is the diagram from Grant that I used in fitting the t-molding. Grant, I hope you don't mind me sharing these.

- door molding.jpg (12.63 KiB) Viewed 1542 times

- offset door hinge.jpg (17.91 KiB) Viewed 1542 times

I have looked at drawings and diagrams. I have put a list of what I want in the TD, and still, my mind has a tough time wrapping around it.

I have looked at drawings and diagrams. I have put a list of what I want in the TD, and still, my mind has a tough time wrapping around it.