Thanks, guys.

halfdome, Danny wrote:Since you'd be towing with your Porsche I'd do some research before you build too light.

A few years ago I drove my step sons 1984 Porsche from Portland OR to the Seattle area which was a real gas, but I wouldn't tow a teardrop with it, it's just too small.

I saw a teardrop at the IRG last year that the guy built it entirely from import plywood which is just under 1/4".

Kind of scary to me, but to each his own.

I'd rather build traditional and tow with a vehicle that can handle the load.

Our life and property is worth the extra expense, besides it's tried & true building practices.

It's just my opinion and others may or may not agree.

Danny

Danny

I appreciate it, Danny. Right now, I'm just in the thinking-out-loud stage. I'm not looking to build a so-light-it's-basically-a-parachute trailer -- if it worked out to 600 pounds dry, I'd be thrilled. My particular trailering situation will involve climbing from seal level to over 7,000 feet in a 45-minute drive, so my initial concerns are 1) not putting undue stress on my transmission during the uphill or the downhill, 2) simply having the power to get the thing up the hill, 3) not boiling brake fluid on the downhill, and 4) not getting pulled off the road when the route gets too twisty or too windy. If there are other important factors I need to think about, I'm here to learn.

Some of this is counter-intuitive, at least to me. I've got three cars, and my first thought was that my best candidate for towing would be my Jeep CJ-7. But then when I thought about it, I realized my sedan had 1) more power (230hp vs 110hp), 2) better brakes (modern disk vs 1980s drum) and 3, better lateral stability (without the Rancho lift kit making things precarious). Aside from that, I don't know if the 911 will ever make sense to put a hitch on. But it's something I'm considering. It's got decent power, great braking capacity and a very low center of gravity. Its achilles heel is no doubt its overall weight (2400 lbs), but in terms of a trailer pushing it sideways, it's better equipped than most to remain stable under lateral loads. It can sustain 1.4 lateral G's in corners, which is better than any tow vehicle, ever, pretty much. That's not the whole story, when it comes to towing. But it's something.

And to be clear: I'm not saying it's a good idea to tow with a car that light. But I'm at the researching stage, still. In my mind, the jury is still out on whether it will ever make sense.

KCStudly wrote:Meant to add that you might want to consider Alaska Teardrop's construction methods. He does a light weight build using steel tube frame and aluminum outer skins. You certainly have the skills and shop for this type of build, converted to a teardrop shape.

Here's one of his builds:

http://www.tnttt.com/viewtopic.php?f=27&t=51991

Thanks. I've looked at his pages and am very impressed. I'm curious as to whether any framing (outside of sandwiching the joints with aluminum L-stock) is essential for strength in a monocoque approach to the trailer I've got in mind. I'm not saying it isn't -- not at all -- and an aluminum or steel square-tube frame is certainly something I could put together. And even though I weld, I've already ruled out aluminum for the tongue and trailer part of the chassis. But for the less-essential parts, I'm looking at aluminum with structural adhesives, mechanical fasteners (like Alaska Teardrop) and TIG welding. I'm still very much listening and learning.

KCStudly wrote:Can the Dibond do a radius?

Is the desire for a lightweight build based on what you expect to be towing with, or is it just sort of engrained in your racing psyche?

Even the traditional method can be built light enough to tow with pretty much anything, especially in the 4x8 size.

There is a unique build going on right now where Robot used a silver paint (

Slipstream build thread). With a little more prep work and a solid base coat (because some of the silver paints can tend to weather poorly) it might suit your needs.

Any reason why you couldn't have a painted foamie wrapped in matte silver vinyl?

Penguino was a tall narrow build that tipped up on its front corner in a 50 mph crosswind in the dessert. Limited damage could have been easily repaired.

Kind of made me laugh a bit thinking about anything that could tip the wide arse on BB2.

But there is a valid point to consider all aspects of a design, including the intended end use and regions/conditions that may be encountered.

In some ways, I'm sure I'm under the influence of racing in this process. Getting things down to race weight while maintaining reasonable safety is not the same thing when you're building a trailer. There's a real penalty to overbuilding in racing. That's not so much the case with a trailer. And a failure is one thing on the track, where everyone understands there are heightened risks -- but much less forgivable when you're driving in front of some ordinary family out on their annual vacation.

I don't think I'd be able to get vehicle wrap to reliably adhere to a sanded and painted canvas/foam structure. But I could be wrong about that. I think I could definitely get it to work with FRP panels, and the wrap might address the lower-cost panels' shortcomings when it comes to UV protection. But I've ordered some aluminum composite samples and I'm going to do some tests to see how they would work.

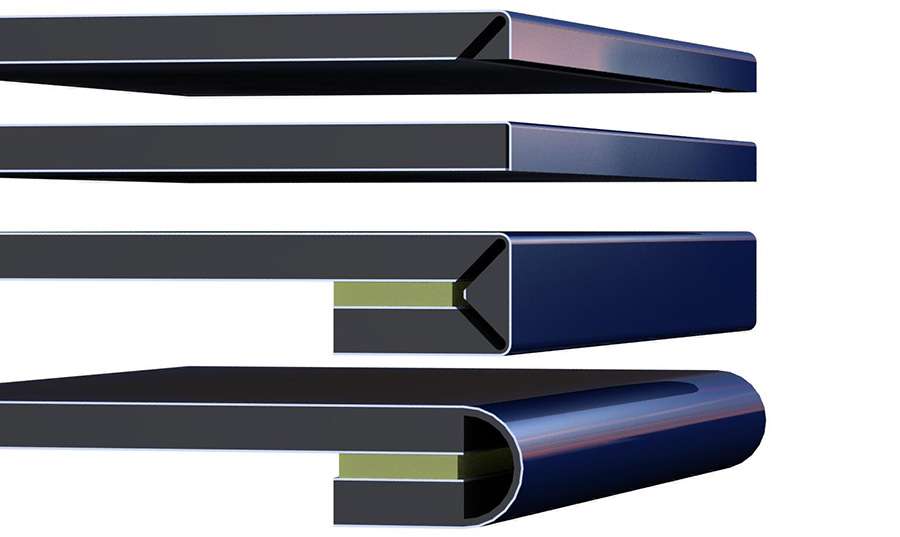

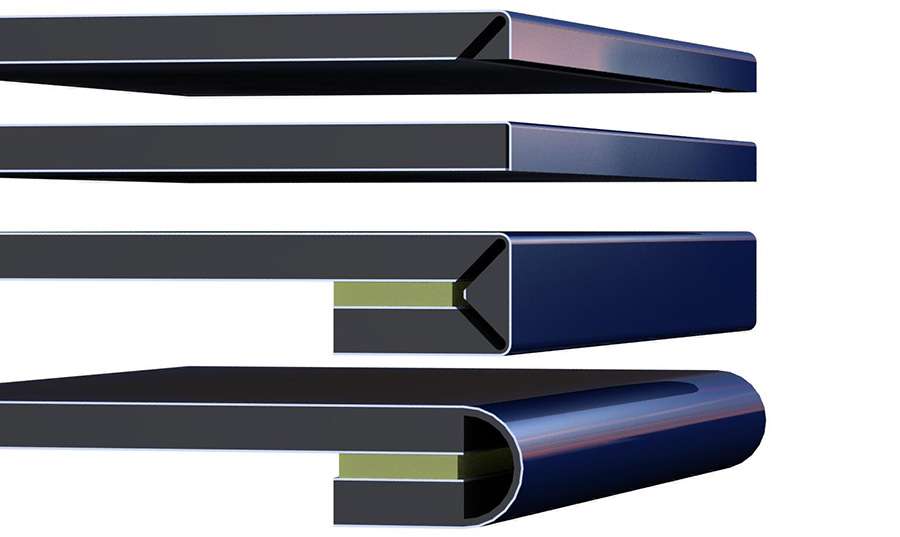

And yes, aluminum composite panels can be square-bent with a brake or radiuses with rollers. They hold the curves you put into them permanently, and that radius can go anywhere from teardrop-size down to the diameter of a pencil:

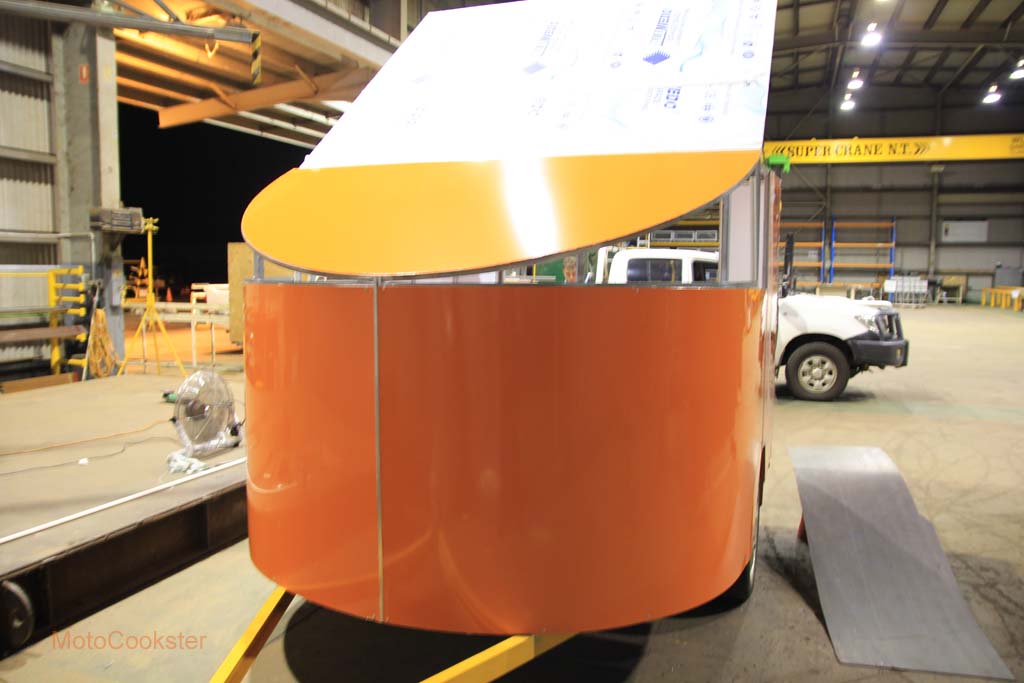

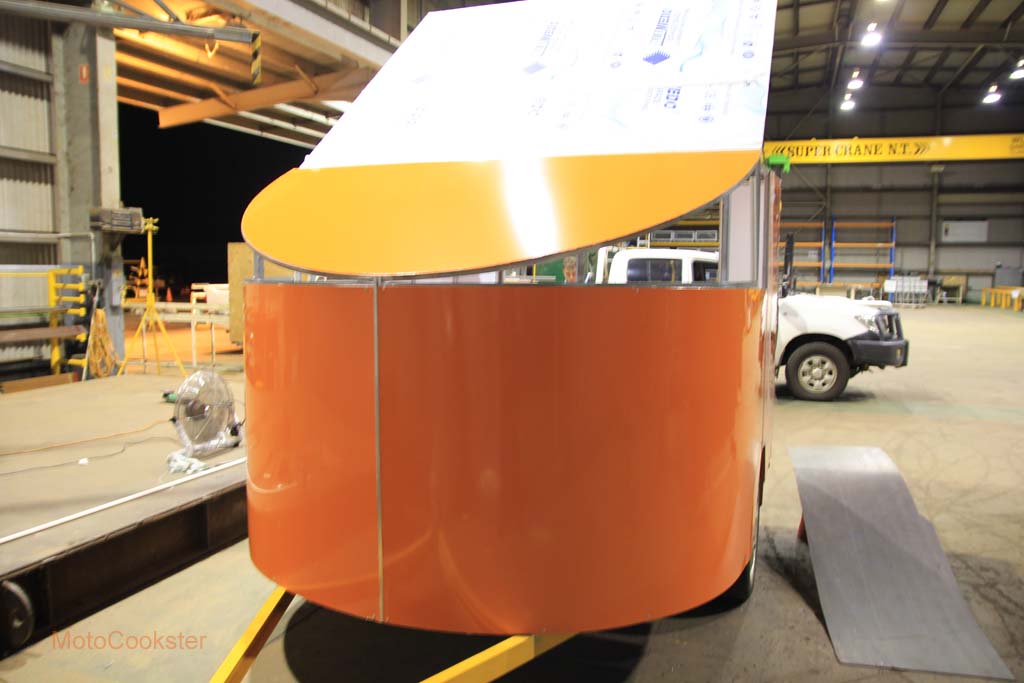

Here are some panels curved more reasonably, for the front of a framed trailer.

)

)

But there is a valid point to consider all aspects of a design, including the intended end use and regions/conditions that may be encountered.

But there is a valid point to consider all aspects of a design, including the intended end use and regions/conditions that may be encountered. I'm a wood-foam sandwiched wall guy. Here's my rig on sixty-miles of teeth chattering washboard road:

I'm a wood-foam sandwiched wall guy. Here's my rig on sixty-miles of teeth chattering washboard road:

We have FaceBook for that ...

We have FaceBook for that ...