Fred -

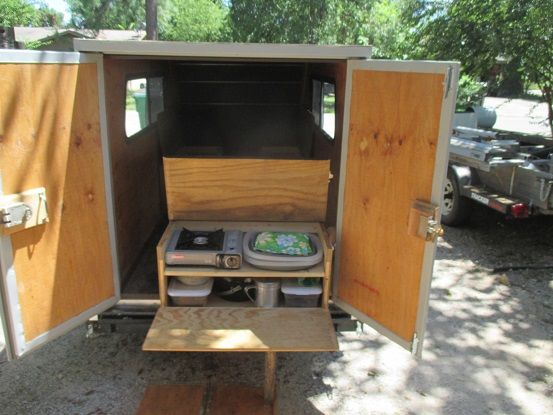

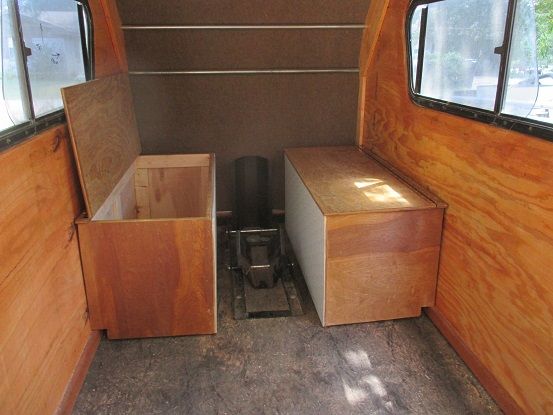

I'll have to pull together some better pics but here is a quick overview.

The doors are 5/8" plywood laminated with FRP. They have a u channel surround made from 26 gauge vinyl coated steel sheet. The bottom has an inregral rain cap.

The rain cap overlaps the door sill which is faced with aluminum angle.

The channel is sealed to the outside face of the door with putty tape and stapled to the inside which will be covered with carpet same as the ceiling,

There is a stop at the inside top of the door frame faced with a self stick closed cell foam rubber strip. Strips are also on the hinge side of the door channel to compress when closed.

The secondary door is secured with barrel bolts top and bottom.

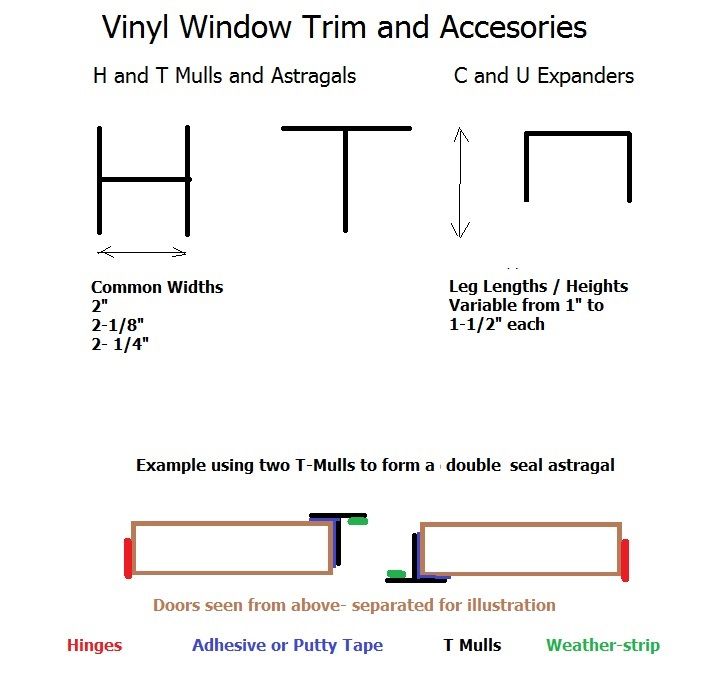

The primary door on the left has an astragal that overlaps the secondary door when closed that will also be weather stripped.

I did not use an astragal on the inside because it would interfere with the surface mount deadbolt lock and striker.

The roof overhangs the top of the doors 4" and extends down the side about 4" also. Clearance is about 1/2". The roof trim will overhang about 1/4" to provide a drip edge to keep rain water from migrating along the underside of the overhang.

All exterior wood to include the door frame and plywood edges are capped with the same custom formed steel sheeting.

The sizing of the roof overhang was just a happy coincidence. The shell was sized to fit within the existing trailer sidewalls allowing clearance for loading and unloading and a setback from my drop-in tailgate which I am reconfiguring to be a fold down loading ramp for the motorbike. The total length of the shell body was 92" and the top is 96" with the mini "Shasta" wings." The width of the finished shell to include the laminated FRP was 47-1/2" which gave me a little fudge to fit then trim the FRP roof.

I used TiteBond III to laminate the sidewalls. The roof with the VHB tape was a one shot deal like contact cement would be. It was surprisingly easy. I prealigned then tacked the lower front edge, rolled back and applied the VHB tape, then rolled into final position. I had clamps and rope ready, but no helper, but it laid out under its own weight, hugging the radius. I used a roller to further compress and seat the VHB before stapling. The trim will be seated with butyl putty tape and a few screws.

The FRP was off the shelf at Home Depot, light gray color. I may paint later to match my Jeep.