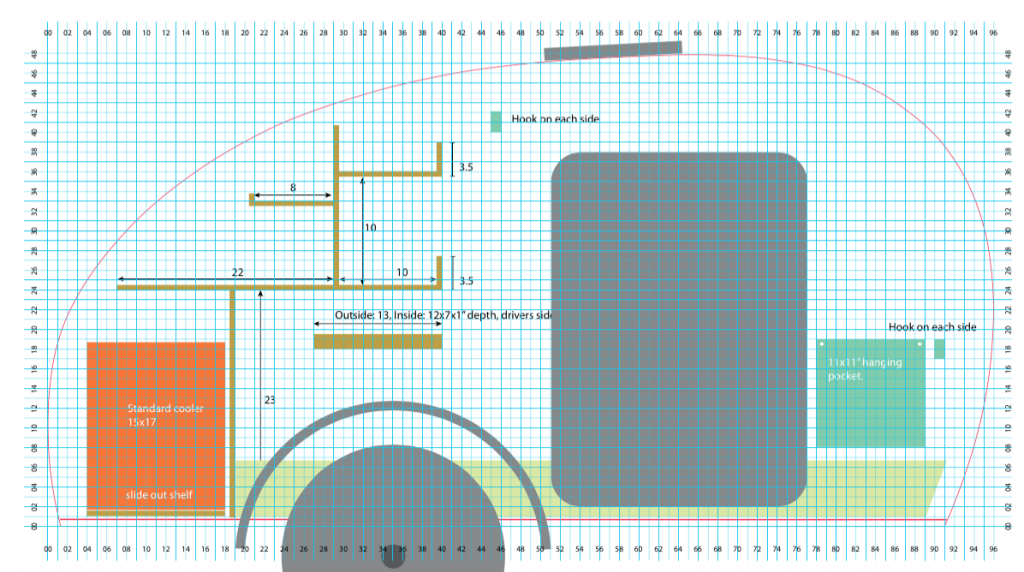

I'm curious as to what's the best way to attach the inner walls to the outer wall.

I've seen people that use dado's in the side walls an insert the inner walls in the slot. That appears to be a real pain.

I've seen people use edging boards screwed to the side walls and against the inner walls. I don't like this as it doesn't look very clean.

I'm thinking about just gluing and screwing through the outer wall into the inner wall with flat-head screws.

Thoughts?

Attach Inner Walls To The Outside Walls

11 posts

• Page 1 of 1

Attach Inner Walls To The Outside Walls

Let the fun begin!

KennyB

My Build Journal: http://www.tnttt.com/viewtopic.php?f=50&t=64385&start=15&hilit=sort+of

KennyB

My Build Journal: http://www.tnttt.com/viewtopic.php?f=50&t=64385&start=15&hilit=sort+of

-

RunnerDuck - Teardrop Master

- Posts: 167

- Joined: Sat Aug 22, 2015 4:26 am

- Location: Coupeville, Whidbey Island, Washington

Re: Attach Inner Walls To The Outside Walls

I've seen people that use dado's in the side walls an insert the inner walls in the slot. That appears to be a real pain.

It's easy with sandwiched walls and makes for an unquestionably stronger joint.

It's easy with sandwiched walls and makes for an unquestionably stronger joint.

Here you can see me cutting in the dado for the lower bulkhead using a router jig.

The two forward dados in the wall are for bulkheads for a headboard with slider storage and a shelf.

It takes some thought–-planning--on assembly, but that's teardrop building.

Tony

-

tony.latham - Gold Donating Member

- Posts: 7073

- Images: 17

- Joined: Mon Jul 08, 2013 4:03 pm

- Location: Middle of Idaho on the edge of nowhere