I rewrote this append several times trying to shorten it, but it has been well over a year since my last append and there is a lot I want to report.

Last year, two days after my last append, I decided to do a ‘hurry-up’ carbon copy of the Tip Top Tier Drop because I figured I had enough time to complete a duplicate before the camping season was over. I was

dead wrong. I ran into a long series of unexpected problems with the frame (none of which were encountered with the 2006 kit).....

1- one of the wheels fit one side but not the other, so something was wrong with the axle.

2- the other wheel did not fit either side, so something was wrong with one of the wheels

3- the tongue arms did not align with the hold down brackets on the front cross member

4- the frame was warped diagonally from corner to corner (would not lie flat)

5- the axle could not be aligned (i.e. perpendicular to frame)

6- replacement parts I ordered the first week of Aug were slow in arriving (did not arrived until a few days before Christmas).

You can find the details in my posts in several threads of the “Trailer & Chassis Secrets” section, mostly in “A Tale of Two Trailers”

http://www.tnttt.com/viewtopic.php?f=35&t=61451. Except for the axle & wheel issues, all the problems appeared to result from poor tolerances, like the difference between these two ‘identical’ tongue angle irons:

Finding the roots of these problems and developing work-arounds took a l-o-n-g time - ALL of Aug & Sept. I did not realize I had a warp problem until I had nearly finished the base half, so I had to disassemble it several times to figure out the cause. Although not totally conclusive, apparently bending the hold down brackets on the front cross member and force fitting the arms into them caused the warping. When trying to flatten the frame, it would only spring back or warp the opposite way.

I was so discussed that I resolved to limit my losses by just finishing it as-is with what materials I had on hand. It was almost done before I lost all hope of getting any camping in during the 2014 season, totally lost interest and did nothing more than install a thin temporary tarp roof for the winter.

This spring I replace that roof (nine months of sun caused deterioration along the tarp seam).

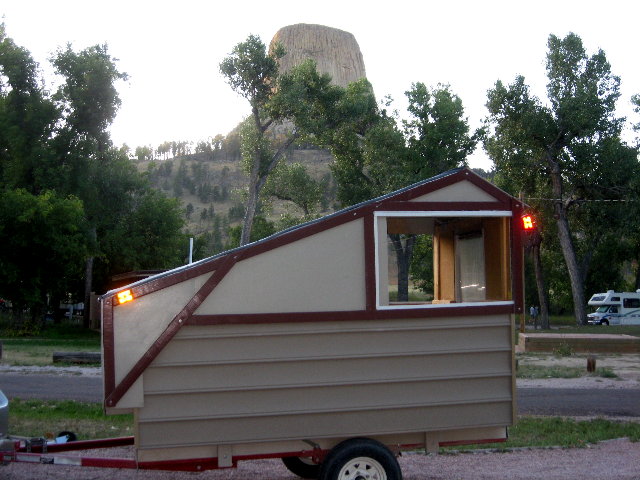

Lacking the heart to disassemble the whole thing to try removing the warp, I decided just to live with the embarrassment of driving around a lopsided eyesore rather than miss any more camping. So I call this trailer the

Tip Top Tier Drop -- Pisa Edition (in honor of the famous leaning tower).

Despite my conviction to “change nothing” in order to save time, I could not resist the temptation to try a few modifications. I lowered the tail lights and reconfigured the framing to (slightly) increase the opened height (which led to more problems, but that’s another story). But the big change was to skin the base with foam and vinyl siding (which required adding braces) rather than plywood. I only cover (‘skin’) one side of the framing. On the original trailer the base used an internal frame while the top’s frame was external, leaving the two smooth skinned sides to slide upon each other. That worked really well, but I wanted to try vinyl and foam even knowing the tiers would not slide or seal as well (because of the margin left for the siding ridges). I only had a few lengths of scape vinyl, just enough for the bottom tier sides, not the front, back or top. Although, I used different types for the port and starboard sides, they are the same color.

Yeah, I know the common street wisdom: ‘vinyl siding will not tolerate highway travel’. This may be true for the staple gun installation used on pre-fab homes, but I used a lot more care and the top partially covers the base in the travel configuration, so I was confident it would not be a problem.

I used half inch thick white foam with foil on both sides, and to my surprise, the unprotected interior side has held up quite well so far. I really like the vinyl, but it does have its down side: Like the original, I can quickly open and close the trailer without help, but the uneven siding does make it more prone to snags while lifting and complicates sealing the tiers.

After a couple of short trips we took it out on a very long one. With a total of 22 nights and 5 thousand highway miles and the vinyl siding has been totally stable.

The inside bed width is a bit over 57 inches. When folded the top is only about 3 feet above the frame deck but when opened we have great head room right where we need it (68 inches at the peak between the foot of the bed and door). But, comparing this to a typical fixed geometry (4 foot wall teardrop), it’s about a foot lower when folded yet has about 20 inches more headroom, so for us the extra work of a pop top is well justified.

I have become quite fond of using a tarp top (light, cheap and effective but watch out for tarp seams). I did not install the center sighting strip on the middle of the roof and I really missed it while backing into sites. Without it the tarp top did bow slightly at highway speeds, but it did not stretch the top and it was no problem at all.

I still hate “making the bed” from the end even if I can stand up during the process. Also, access to things stored under the very front of the bed is limited to when the bed is folded forward, so you have to be sure to put anything you might need during the night under the foot of the bed.

Now I need to decide what my new tow vehicle is going to be before I start a new trailer and relegate this one to utility hauling. I’m pretty sure I will be using as much vinyl as I can and that it will be some sort of pop top, but I will be a lot more careful selecting a frame.