Steel siding?

20 posts

• Page 1 of 2 • 1, 2

Steel siding?

Yes, I know this is going to sound nuts! I am wondering if anyone has ever used steel siding for their teardrops or other travel trailers for a skin? I realize it is about 2.5 times as dense than aluminum, but thin gauge would hold up better against rocks, hail, and such when compared to aluminum. It appears to be much cheaper per sq. ft. I can get it in about 20 different colors, all with a 40 year warranty. It is 29 gauge and they want about $3.12 per linear foot at 40 7/8 inch wide. It is local, and they can do any length up far beyond what I could ever need.

I know seams would be a issue, I would end up with seams either vertically or horizontally. Is there a way to seal the seams? I have a enclosed cargo trailer I rebuilt the frame for, not sure what they used for the sides but a magnet won't stick to it. I assume aluminum also. They used vertical seams, with the front pieces on last, and the first one on were the rear. The end of each panel, over lapping about 2-3 inches. I never seen any leaking of any kind at the seams. Has anyone used used a method of sealing seams on a roof that is wider than normal? My roof currently is looking at about 6' to 6'6" wide.

I know it will be heavier long run, but I am also pulling with a 3/4 ton truck, my idea is based on a gooseneck trailer design. Thanks! - James

I know seams would be a issue, I would end up with seams either vertically or horizontally. Is there a way to seal the seams? I have a enclosed cargo trailer I rebuilt the frame for, not sure what they used for the sides but a magnet won't stick to it. I assume aluminum also. They used vertical seams, with the front pieces on last, and the first one on were the rear. The end of each panel, over lapping about 2-3 inches. I never seen any leaking of any kind at the seams. Has anyone used used a method of sealing seams on a roof that is wider than normal? My roof currently is looking at about 6' to 6'6" wide.

I know it will be heavier long run, but I am also pulling with a 3/4 ton truck, my idea is based on a gooseneck trailer design. Thanks! - James

- Vajra

- Teardrop Inspector

- Posts: 24

- Joined: Sat Jan 02, 2016 7:00 am

Re: Steel siding?

Are you thinking in terms of a 40" wide flat sheet or will it have a profile or ribs like corrugated, r panels, or v crimps?

I used steel exclusively on two of my trailer exteriors and for trim on two others.

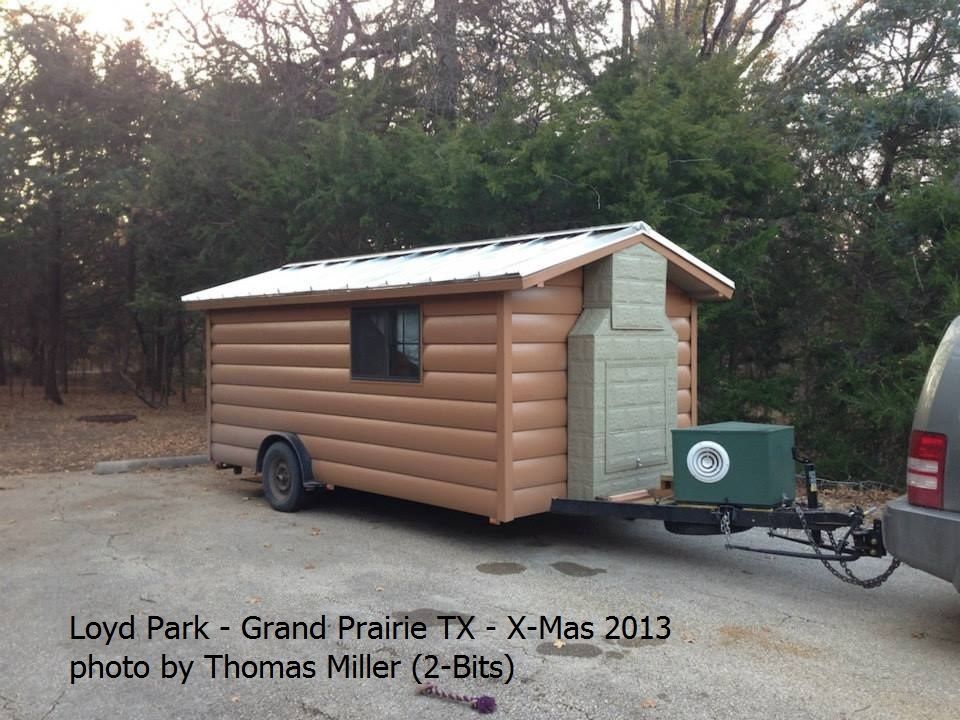

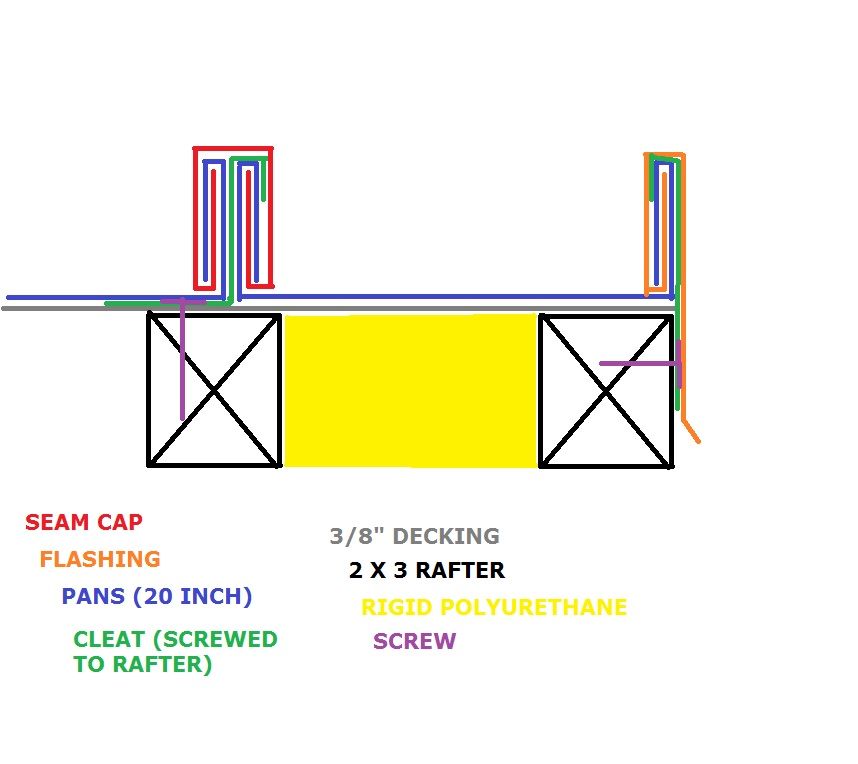

My siding is roll formed, one in a faux log profile, the other in a board and batten pattern. I also made standing seam roofs for both.

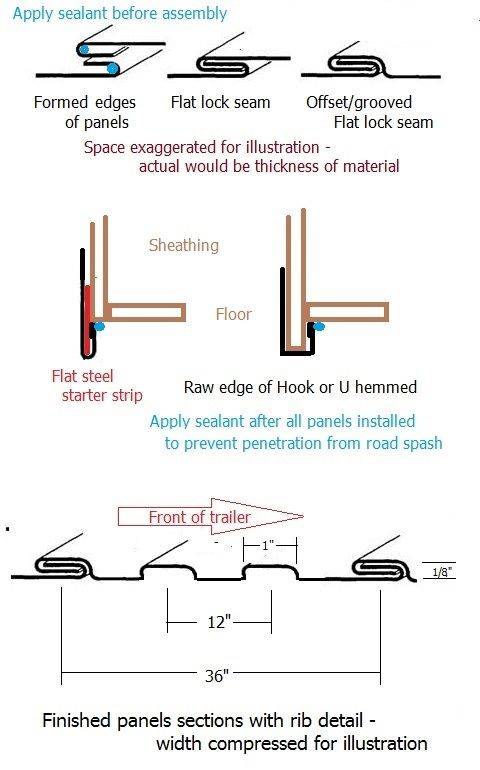

Joints, seams, trim, etc. can be problematic depending on your design but overcoming with proper techniques and flashing will solve all.

Most trailer manufacturers using flat sheet just lap joints with sealant between then rivet or screw. Others use VHB tape to seal and join the sheets and attach to structural members.

You need to have and know how to use a metal brake to do it the right way. Just my opinion.

M C

I used steel exclusively on two of my trailer exteriors and for trim on two others.

My siding is roll formed, one in a faux log profile, the other in a board and batten pattern. I also made standing seam roofs for both.

Joints, seams, trim, etc. can be problematic depending on your design but overcoming with proper techniques and flashing will solve all.

Most trailer manufacturers using flat sheet just lap joints with sealant between then rivet or screw. Others use VHB tape to seal and join the sheets and attach to structural members.

You need to have and know how to use a metal brake to do it the right way. Just my opinion.

M C

-

M C Toyer - The 300 Club

- Posts: 363

- Images: 11

- Joined: Thu May 31, 2012 8:59 pm

- Location: Pilot Point (Denton County) Texas

I was thinking much like lap joints, but not sure how else to seal it up. The roof would be the challenge at 6' to 6'6" wide. I guess I am not sure what VHB tape is, or how it is used to join the sheets. Sounds interesting. I have access to a 48" manual brake that can do up to 22 gauge. Please share anything else you know!

I was thinking much like lap joints, but not sure how else to seal it up. The roof would be the challenge at 6' to 6'6" wide. I guess I am not sure what VHB tape is, or how it is used to join the sheets. Sounds interesting. I have access to a 48" manual brake that can do up to 22 gauge. Please share anything else you know!  She might have rust, but given she is about 64 years old, I would say that it has aged pretty well. How does she pull and how is she holding up? Great picture.

She might have rust, but given she is about 64 years old, I would say that it has aged pretty well. How does she pull and how is she holding up? Great picture.

My walls are looking to be about 3.5 inches thick minimum. Why so thick, extra insulation. Gets cold here during winter and I still plan on using it. Might not to the full thickness, but the 2x4 and 2x6 framing would allow it. Sounds like over kill to most, I have my reasons though!

My walls are looking to be about 3.5 inches thick minimum. Why so thick, extra insulation. Gets cold here during winter and I still plan on using it. Might not to the full thickness, but the 2x4 and 2x6 framing would allow it. Sounds like over kill to most, I have my reasons though!

BTW, yes, I have indeed thought that a seam should never face forward. The reason we talking about lengthwise, was if it is thew best option. Which I doubt, but it could be done. He said it is possible to do a bottom sheet, then top sheet, with a mid-center lap joint. All water would shed downwards. The roof could have a slight peak, with a center trim cap that would act like a house. I also realize, this would be harder to make. I have thought about other design changes, but I don't know that I will go that route, even if cool or unique.

BTW, yes, I have indeed thought that a seam should never face forward. The reason we talking about lengthwise, was if it is thew best option. Which I doubt, but it could be done. He said it is possible to do a bottom sheet, then top sheet, with a mid-center lap joint. All water would shed downwards. The roof could have a slight peak, with a center trim cap that would act like a house. I also realize, this would be harder to make. I have thought about other design changes, but I don't know that I will go that route, even if cool or unique. never recall seeing a fiberglass faced wood sheathing. Going to have to go see some.

never recall seeing a fiberglass faced wood sheathing. Going to have to go see some. - James

- James