With the outside of the door built up it was time to work on the inside of the door. The layers of the door (from outside in) are the 1/16" aluminum skin, the 1/2" honeycomb, a 1/2" wood perimeter frame with foam insert, a 1/4" layer of foam and the 1/4" (5mm actually) birch plywood skin. The thickness ended up as 1.51" total (probably one of the thickest teardrop doors around). The thickness was more than I originally planned but was driven by the need to get the door latch to align to the inside steel frame and because of the door edge bulb seal it stands out more that originally planned.

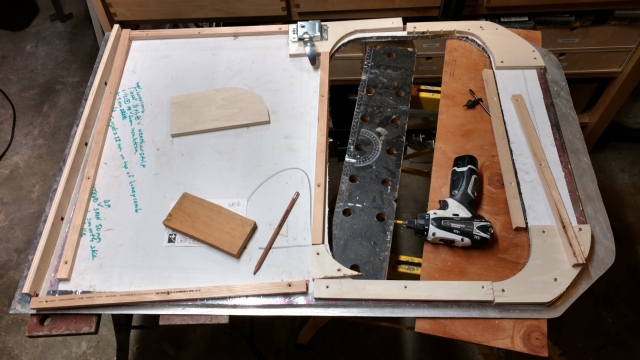

Here is the layout of the wood perimeter frame:

I had two reasons for the wood perimeter frame. First was to have a place to fasten the trim band around the door (its not easy to get fasteners into the edge of honeycomb or the edge of the door skin). I was also getting anxious about how well the bulb seal might hold up and keep water out. The door is extremely stiff and will lay against the wall having a steel frame so warpage or deflection will be minimal but I wondered about road spray and whether the seal might wear or dry out over the years. This lead to the second reason for the wood perimeter - I included a kerf cut in the edge of the frame to insert another door seal to fit inside the door jamb. Maybe I'm just being paranoid (and this thinking may be why it is taking so long to build this trailer).

I left a larger area in the frame where the door latch will be mounted so it has a solid footing (just below the window on the far side in the picture). Here's the door with the 1/2" insulation in place after the wood frame was screwed to the aluminum honeycomb panel.

To get the door thickness just right for the latch alignment, I needed a light weight 1/4" something and settled on a cheap floor mat from Harbor Freight. One package provided just enough material for both doors and provides a little extra insulation over the wood perimeter frame, and it is just stapled in place to keep it from moving.

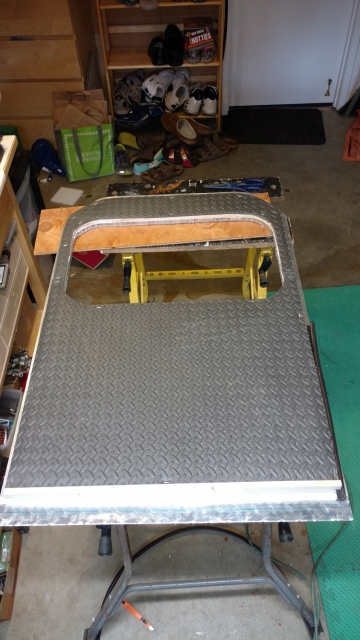

I checked the thickness with a scrap of the 1/4" birch plywood and the aluminum edging from Vintage Technologies I've had for almost 2 years. The saw kerf in the wood frame is exposed just below the aluminum edging but hard to see with all the shiny surfaces in this picture.

The next layer is the plywood interior skin. I had cut out the whole interior side skins about 2 YEARS AGO and they have since been laying face down on the trailer floor, the right skin on top of the left skin. The backsides got scraped and even a few brown scorch dots from the little welding I did last year but the fronts were still clear. I had to clean out the inside of the trailer to move out materials, scraps, and parts to get to the skins so I could cut the door skin.

I propped the left skin up inside the trailer and outlined the doorway then cut it out with a jigsaw.

Since the skin was laying face down on the trailer floor build with rivets so there are dimples in the wood skin. They can be seen here within the window trim ring. Although these dimples will be cut out for the window, there were others that in areas that will remain.

I was able to restore the flat surface almost completely using a trick I learned many years ago from a cabinet maker, using a hot steam iron to pump up the wood with steam blasting it until smooth. I did this on bare wood rather than stained to penetrate better and to avoid getting into trouble for possibly ruining the main household iron.

This picture is actually from the right door done a couple weeks later but its the only picture I have of what I did. The ironing took only 10-15 minutes for all the areas on each door skin - I probably could have stopped sooner but I wanted to keep going until I couldn't get it to flatten any more and the last few minutes didn't make much difference.

Here is the door skin with a natural stain installed trimmed.

then placed in the doorway with the edge band seal installed to check fit. <edited to correct this last picture link>

So far, so good (and so slow). My next entry will describe the "fun" I had with the windows in the door.

At least I saw one crack then it became more evident there and on other joints too. The welds were actually well done but all in the same plane and with the slight racking forces in that plane was more than they could handle.

At least I saw one crack then it became more evident there and on other joints too. The welds were actually well done but all in the same plane and with the slight racking forces in that plane was more than they could handle.