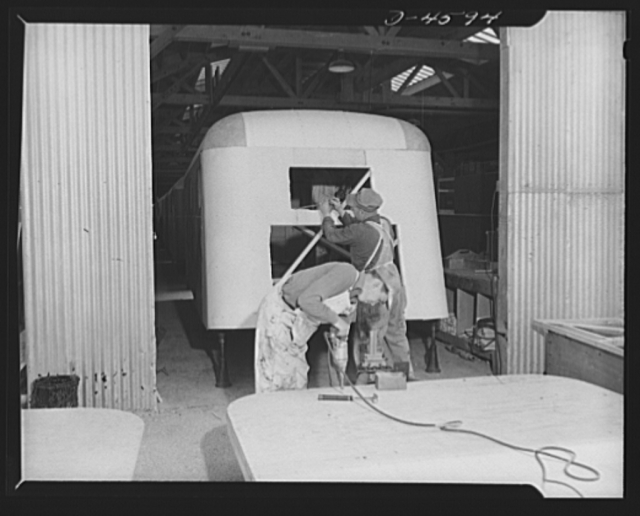

This is from the Library of Congress. In WWII, Western Trailer Company made wartime trailer housing - essentially travel trailers - using molded paper components. From the LOC website:

"Overcoming metal shortage is a big problem in trailer manufacture. Western Trailer Company of Los Angeles has been able to replace metal fenders (wheel wells) successfully with plastic material made by a new process. Paper of forty pounds weight runs from rolls to a tent containing a glue-like solution. After it absorbs this solution, the operator breaks its stiffness by wadding and squeezing."

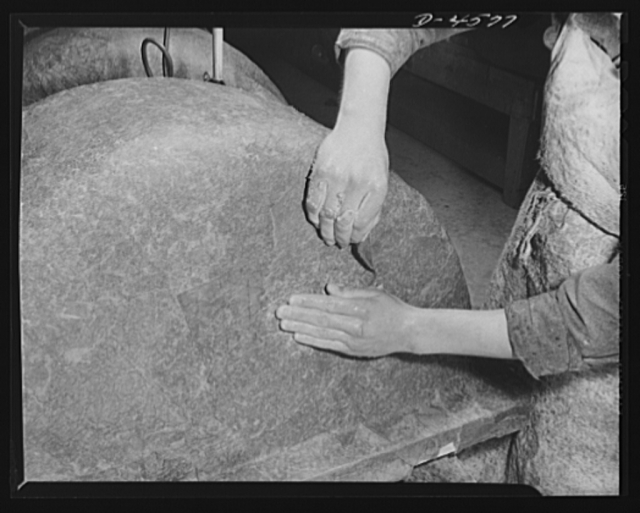

"Wadded-up paper, impregnated with a glue-like solution is smoothed into place over molds in continuous layers. The material is self-hardening and self-compressing. When dried, it is sanded, sawed and drilled, and may be installed with nails, screws or bolts."

"Here, a worker shows a finished wheel well ready for installation. It is made of successive layers of paper impregnated with a hardening solution. The finished wells are covered with an asphaltic preservative paint."

In this picture, you can see the trailer corners that were also made using this process.

I don't know why something like this couldn't be scaled up to do a teardrop or tiny travel trailer.

Paper mache done this way dries to a pretty hard surface …

Paper mache done this way dries to a pretty hard surface …

Leave to you Tony!!

Leave to you Tony!!

In days of yore it might be said that he tends to squeeze his nickels until the Indian is riding the buffalo!

In days of yore it might be said that he tends to squeeze his nickels until the Indian is riding the buffalo!