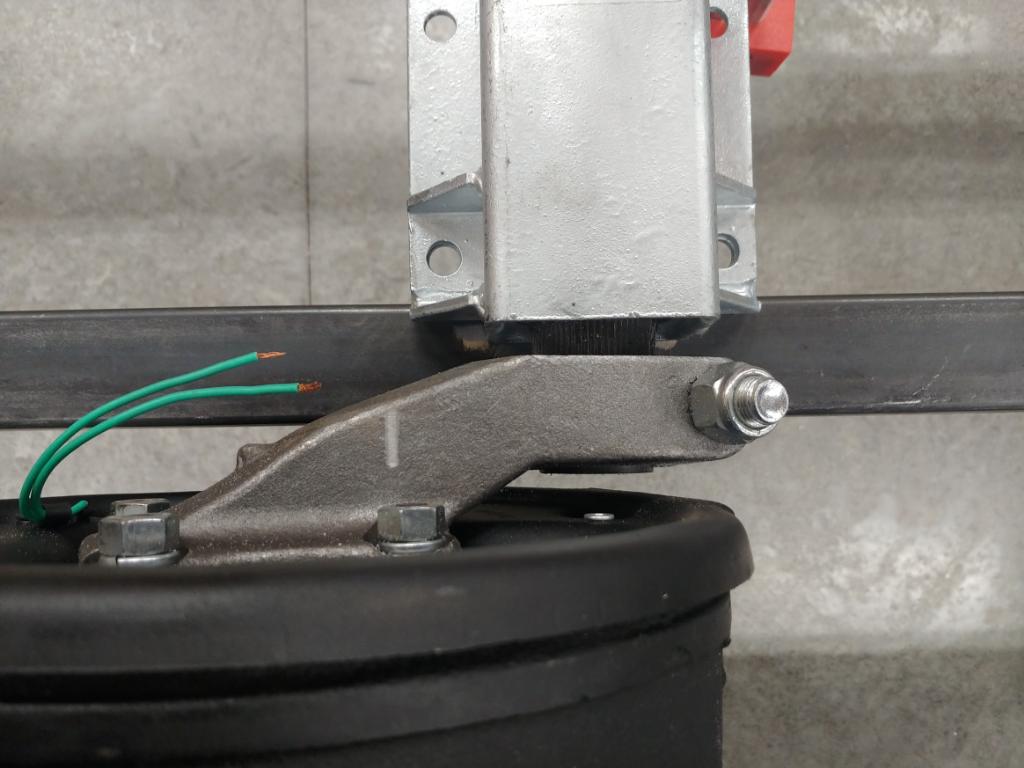

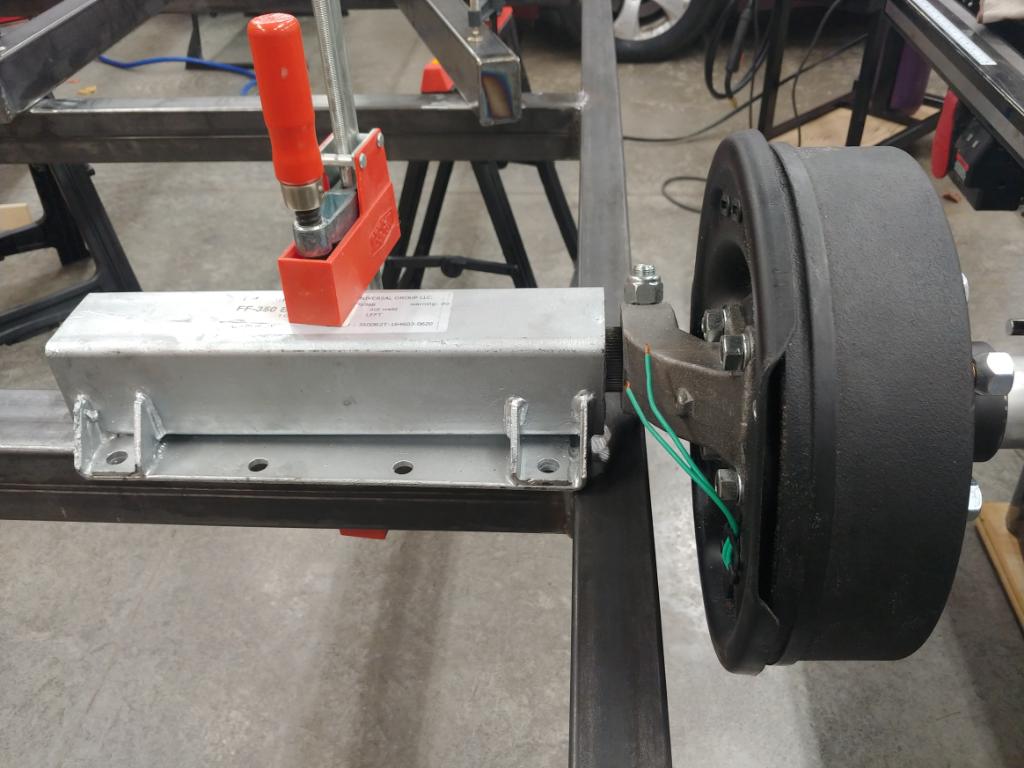

I am running Flexiride 3500# half axles and am concerned about axle placement over the outside frame rails. I emailed the techs where I purchased the axles and they gave some advice, but I am still not sure how I want to go. I can think of 3 possibilities right now.

Here are some pics of what I am talking about.

- rps20201104_080609.jpg (78.98 KiB) Viewed 2417 times

- rps20201104_080547.jpg (69.46 KiB) Viewed 2417 times

- rps20201104_080525.jpg (82.46 KiB) Viewed 2417 times

My options as I see it are:

1. Mount as pictured and with the maximum "down angle" of 24 degrees and cross my fingers that they dont bottom out. This is what the techs suggested that if they are mounted with the maximum down angle, frame contact should not be an issue unless they are overloaded. This is a small trailer build so I am anticipating the axles to be "under" loaded all of the time (different problems I know).

2. I can mount these with the bolt hole closest to the frame rail on the outside of the frame. This would work also except it would provide slightly less weld length. This would be the most "robust" way to do it as I would not have to worry about bottoming out, I would only need to mount the fenders high enough that the wheel would not contact. This makes some added weirdness as I was not planning on having a gap between the side wall of the trailer and the side of the fender. Mounting on the outside would result in an ~2" difference.

3. An alternative would be to add a "lift kit" of sorts. I would mount as pictured except I would add a 2" spacer between the axle and the plate. Im thinking a 2" square tube with 4 holes drilled in it running the length of the plate. Two of these front and back of each plate would provide an additional 2" of clearance. The nice thing about this is it could be done after mounting via option 1.

4. I could mount with the far left holes square over the side rail and drill through with either added sleeves or with a 1/4" plate on top to distribute the load (and without sleeves in the 2"x3" x14ga rectangle tube side rail?).

As of writing these are in order of my current preference. Especially given that option 1 can be modified by option 3 if needed. Would not have to be 2" either, could try 1" or less as well (1/2" plate or bar across them as well. I suppose another option would be to weld on two pieces of 1/4" angle stock to each side and extend the mounting surface down by an inch or two. That seems complicated though.

Any thoughts, I would really appreciate hearing them.