* More photos would help a lot. Can't really tell what your tongue may be tied into or how it's connected up front; it might need to be scrapped entirely, instead of straightened & braced.

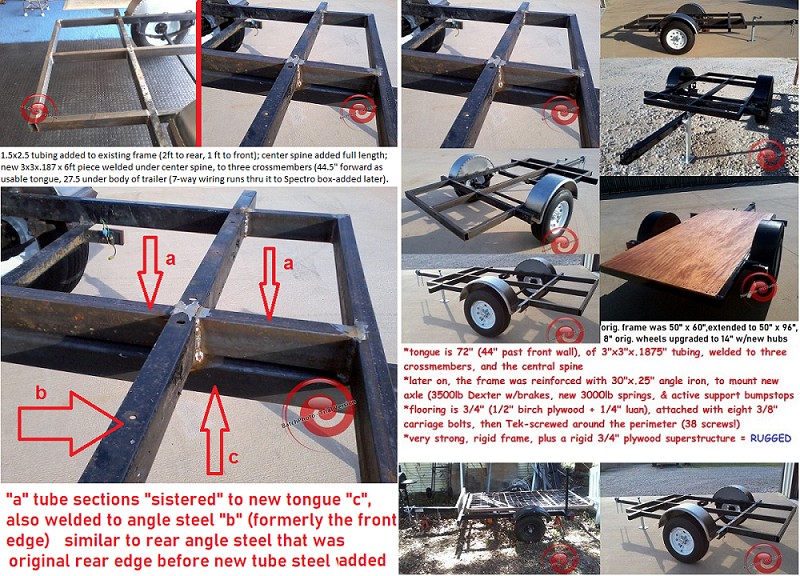

* My trailer's original tongue was bent, and too short to be used, when I expanded its' size (from 50"x60" to 50"x96"), and a bit too thin (just 11 gauge) for a single beam tongue, IMHO. So, I used a 72" piece of 3/16" thick 3"x3" square tube to replace it, tied into 3 crossmembers, and sistered to a central spine running the length of the trailer. It's been proven to handle the 2200+ lbs weight of the trailer quite well, and the 266 lbs tongue weight, too.

- welded pieces added to enlarge original frame.png (1022.6 KiB) Viewed 1296 times

* However, if I ever get offroad, I think I'd make the current added-on tongue box "stabilizers" (punched-hole,

galvanized, angle steel... just bolted on) into real supports for the tongue, turning it into an A-frame style tongue, by welding 1/4" steel angle pieces diagonally from tongue to two crossmembers under the front. As-is, I check the current set-up for straightness and/or cracks (near welds) after each trip, just to be sure.

* You have three weeks until your next trip...which should be enough time to fix the tongue so you'll be assured of safety. I was quite inexperienced at building a trailer, with little welding skills (pure novice), so I had help with my frame from an expert. It was done in a couple of weekends, a little at a time (as I acquired the steel). Then, 2.5 years later, I added a new axle, fabricating new frame mounts & reinforcements over about the same time period, all by myself., in a hurry before a trip. So, it can be done...especially if you can find an experienced welder or a weld shop near you. Probably easier than finding an automotive frame shop that's willing to do it.