Spent most of the holiday weekend "living a little" rather than working on the teardrop. However, my wife and I still managed to get a few things completed during the mornings before any of the days' activities started up.

We got the hatch insulated, wired, and the blocking installed for the galley light and license plate bracket. Honestly, I had been planning on not installing a license plate light. At the last minute prior to being ready for the exterior skin, I looked up Michigan's trailer laws and realized a license plate light was required for all trailers. I'm glad I took the time to check, since going back and wiring it later wouldn't have been possible.

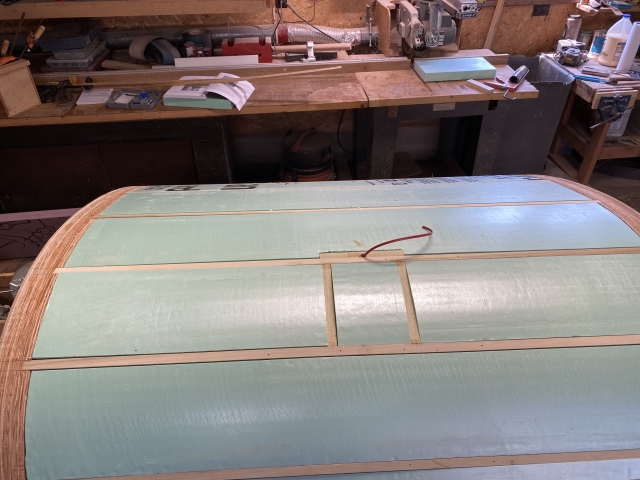

Next, we got the exterior skin installed on the hatch. It was a good feeling to know that we were done constructing the "shell" of the teardrop at this point. We followed the same method I used for the interior side of the hatch to install it, however, I used crown staples instead.

After the hatch was completed, I sanded it and rounded over the outside edges to match the rest of the roof line. Both the hatch and the roof of the teardrop will be getting fiberglassed later this week, once I've gotten everything sanded.

I was also able to crank out the third brake light mounting block. We glued two scrap pieces of oak together for this. I was somewhat curious as to how others have made the angled cut once it's glued since its a fairly wide piece. After giving it some thought, I remembered a youtube video I'd seen a while back where a planer sled was made. I decided this would be a good time to try making one myself. I screwed in blocks surrounding the light block and used additional blocks to prop one side of it up at an angle so that it would plane the block at an angle. It worked well and I'm happy to have one more woodworking trick in the toolbox.

Last, we got the interior reading lights installed. There wasn't much room to stuff the wires behind these, so I opted to solder them. It was my first time, and it definitely showed. I may be going back to fix those connections one day... Thankfully they're easy to access.

We're excited to prime and paint this thing soon. Choosing a color wasn't easy for us since we ordered all 63 of Monstaliner's color samples and were overwhelmed with options that we liked. The Monstaliner has been sitting in the corner since we got it on a Memorial Day sale and I've been anxious to use it. Just a whole lot of sanding to do before and after fiberglass before we can crack it open.