.

About 4-1/2 more hours Saturday.

Cleaned up sanding dust from last session. Scuffed lows. Wiped with towel just dampened with acetone. Another full coat of fairing filler on most of the street side wall. I could have tried to just fill all of the numerous low spots, but I’m still experimenting and trying to develop technique. With Mike’s advice to add more one time and take off once, not knowing where those target points are, it is taking me a few iterations to figure it out on this large scale. Rear section first, then front.

I mixed five (5) batches varying between 4, 5, 6 and 8 pumps, depending on my estimation of the amount needed to complete a particular section. Six (6) pumps to start the rear area; not nearly enough. Eight (8) pumps more; worried it might go off in the cup by the time I mixed in the filler. Not to worry, it seems as though the filler helps slow the initial reaction. Five (5) pumps to start the front of the wall section. Two four (4) pump batches used to pick up stray areas around the the edges and light recesses. There were a couple of areas that didn’t get an extra coat, but they were well fared already, and I was getting tired by this point.

When mixing larger batches of the fairing filler I use the full size (not cut down) large ice coffee cups. The fairing filler is so light and fluffy that it usually takes two additions to get it mixed in, and the high sides of the cup help keep the filler in the cup until it gets mixed in. I think it’s easier to add it in two doses because it incorporates easier in the wet slurry stage, leaving less to incorporate once it thickens up and gets harder to stir. I think it gives me better control on the consistency, too, making smaller final additions to creep up on the consistency I want. Not possible to weigh the filler as it is as light as air.

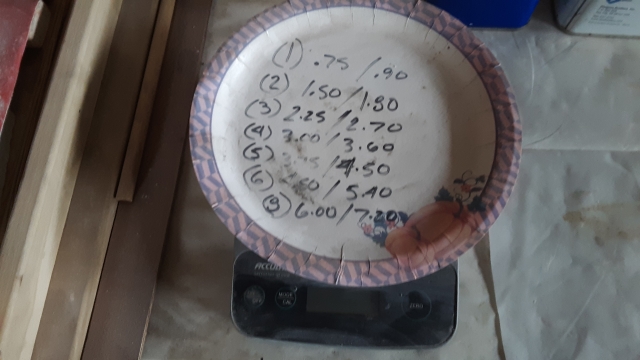

A note on using the pumps as well as the digital scale. After leaving the resin and hardener for a bit, just left the pumps in place, I think they get a little restricted. Prior to this recent uptick in build activity I had been using the fast hardener from one of the small cans with the short pump straw. With the spring temperatures on the rise, knowing I would be using larger batch sizes, I switched back over to the slow hardener and longer medium length pump straw for the quart sized cans; which meant I had to clean the hardener pump out with some acetone so as not to cross contaminate. Whereas the resin is the same and comes out of a gallon can with the big long straw pump that I didn’t bother to clean out. So by weighing my cups I could see that the resin was coming up short by almost a full pump, whereas the clean hardener pump was only coming up short by the typical .05 oz (about the resolution of the scale). Again, I keep a paper plate as a drip catcher zeroed out with the empty cup on the scale. Right on the plate I have written the resin and total batch weights for various batch sizes per pump stroke.

Rather than pouring into the cups, using the pumps is neater (no spillage or need to wipe the spouts and tops of the cans… although in storage I turn the pump spouts back over the tops of the cans and they always seems to drip a little now and then), keeps me from over pouring and screwing up that way, too.

I always leave the cups out of the trash so I can check them the next time and make sure the batch cured well.