Question is, what would be the best method of sealing? Poly chalk, butyl tape? Seems like there are countless chalks and methods. I have seen some sailors use just poly sealant for frameless windows but that seems like a mess. I am probably overthinking this one too.

Need Sealant suggestion

17 posts

• Page 1 of 2 • 1, 2

Need Sealant suggestion

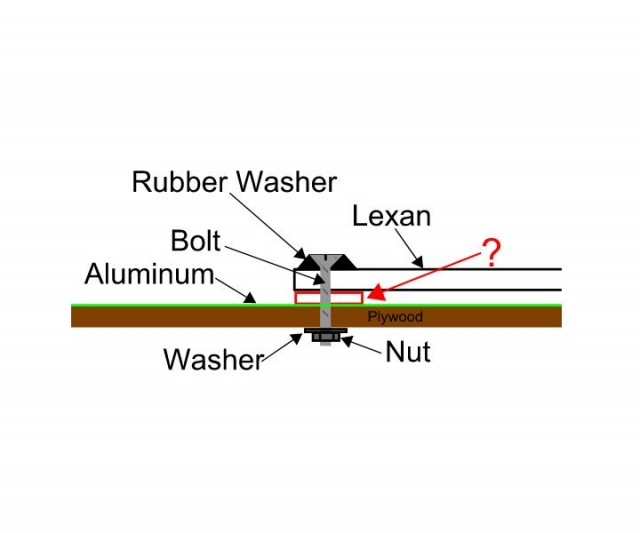

After much research and planning I chose a trimlock seal for my stargazer window. Well, I need to go to plan B. After adding the aluminum to the plywood, it's too wide for the trimlok. I knew this was potentially a problem and I could sand the ply down. Really not a good solution, I returned the trimlok and now just want to mount the Polycarbonate down flat to the roof. I am sure someone has done this but I could not find anyone here.

Question is, what would be the best method of sealing? Poly chalk, butyl tape? Seems like there are countless chalks and methods. I have seen some sailors use just poly sealant for frameless windows but that seems like a mess. I am probably overthinking this one too.

Question is, what would be the best method of sealing? Poly chalk, butyl tape? Seems like there are countless chalks and methods. I have seen some sailors use just poly sealant for frameless windows but that seems like a mess. I am probably overthinking this one too.

-

Onajourney - Teardrop Master

- Posts: 259

- Images: 181

- Joined: Mon Sep 06, 2021 2:16 am

- Location: Central North Carolina

Re: Need Sealant suggestion

I don't think you are overthinking this since they do like to leak. You might take a look and see how John tackled this issue: https://www.tnttt.com/viewtopic.php?f=50&t=73779

Tony

Tony

-

tony.latham - Gold Donating Member

- Posts: 7073

- Images: 17

- Joined: Mon Jul 08, 2013 4:03 pm

- Location: Middle of Idaho on the edge of nowhere