gudmund wrote:after replacing your axle you may want to check out the adding of a set of SumoSprings "TSS-106-40 trailer springs" between your existing leaf springs and frame. They are very easy to mount and install. Note - at the end of each year (Nov/Dec) Sumo usually puts everything they sell on sale = 15%to 25% off and this kit - thou 'not cheap' - runs around $200 but does seem to work well with leaf springs. (see pic)

the left half of this pic is of fellow 'TnTTT' member "working on it" from Texas that he built himself = his 'poor man's' version - the right side pic is of my SumoSpring set-up = $$$. "working on it" stated his set-up works just fine and I am sure he spent 'alot' less on his set-up than I did on mine. But either set-up could be something else too think about.................

another thing to think about if you do end-up replacing the axle = buy the heavier duty one along with getting it a couple inches longer so as to be able to quite 'having the need' to use the "wheel spacers" for the bigger wheel/tires (you might want to size it up for even more extra room for an even a larger set of wheels/tires - say 205/75-14/15's............in the future)

My trailer originally had a very weak axle with 8" wheels. I first changed the wheels to 14", after adding larger hubs/bearings and a 1/2" spacer/adapter (for frame clearance), while extending the frame fom 50"W x 60" L to 50"W x 96"L. I knew it was way too small for the 1400+ lbs (as loaded for my first trip) total weight. But, I was on a limited secret budget.

About six months later, while lifting the trailer in the garage (for a nut/bolt check & undercoating refreshening), I heard the right rear spring hanger tear loose, so I jumped on the chance to upgrade the axle to a larger one. By that time, my trailer was no longer on a "secret" budget. I ordered a 3500 lb Dexter axle, with brakes and easy-lube spindles, bought new spring hanger sets, hardware, and 3000 lb spring pair and proceeded to upgrade. The trailer's weight was going to increase, over time, so I went big on my choice of springs.

I was correct to do so, as my 4x8 trailer now weighs 2225 lbs.The torn frame on the right rear needed reinforcement, so I added 30" L 2"x"2" angle iron (1/4" thick), to each inner framerail, and 30"L x 2"W flat iron (3/16" thick) to each inner framerail. They were bolted/welded/glued to the existing frame, as were the spring hangers attached to them.

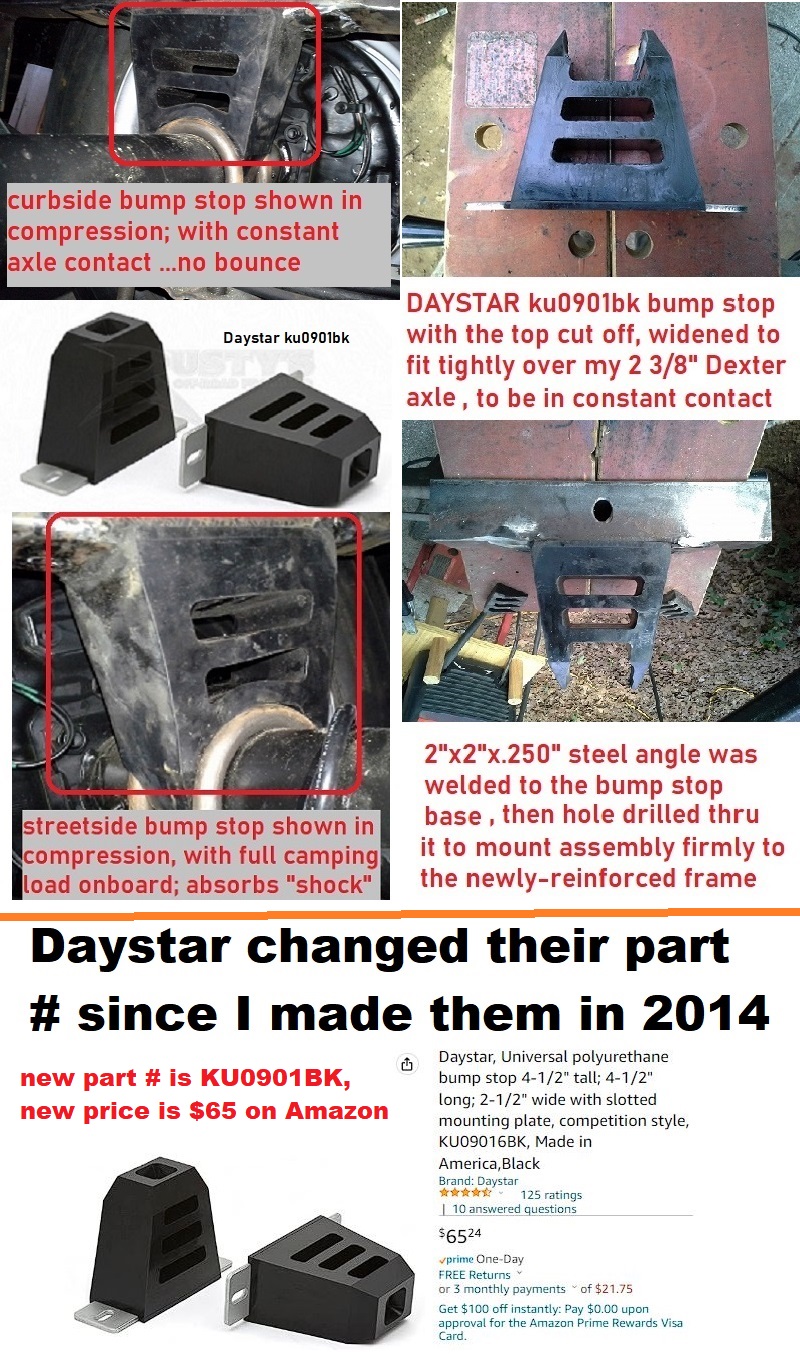

I had broken some springs on my car hauler trailer previously, so I fabricated what I call "progressive, active bump stops", that are bolted in place between axle and frame, always in contact so all spring action is absorbed (and the springs will never fold inward, and break). If the ride had been too firm, I could've cut a central ligament of each bumpstop to soften the ride, but it wasn't neccessary. They've worked fin for 8+ years, now.

- Active suspension Daystar bumpstops.jpg (457.3 KiB) Viewed 3453 times

- how it works (theory).jpg (125.08 KiB) Viewed 3453 times

Years later, I found that Sumo and Timbren had their own versions of the "progressive, active bump stop".

gudmund showed the Sumo, and here's the Timbren

- timbren bolt-on active offroad bumpstops.JPG (54.5 KiB) Viewed 3453 times

much more expensive, and for 3" diameter axles, not 2 3/8"