I'm hoping to get started on my own TD after the first of the year, and need to decide exactly how I will build it. I plan on making "sandwich" type walls, so I can insulate them, and hopefully save a little weight.

Why does everyone seem to install the interior paneling after the sides and ceiling ribs are in place? Wouldn't it be easier to make the walls, complete with interior paneling, first, then wrap the ceiling over them, next add the cross ribs and insulation, then finally the roof?

Most of the construction pictures show people putting the ceiling paneling in after the ribs, then having to figure out some way of jaming or clamping it in place. Wrapping the ceiling first, then adding the ribs seems like it would be a lot easier.

If I use baltic birch for the ceiling, can I get away with just one layer in the ceiling, and 2 layers on the roof (do I really need 2 on the roof?). I plan on putting aluminum over the wood.

I noticed on one site that the builder used hardboard for the roof (under the aluminum). Would this be strong enough? Doesn't really seem like it would save much money. Any good reason to use hardboard?

Wall & Ceiling construction

12 posts

• Page 1 of 1

Wall & Ceiling construction

Jeff & Odie

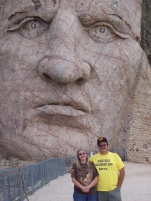

Black Hills of South Dakota

Black Hills of South Dakota

-

JunkMan - 500 Club

- Posts: 974

- Images: 50

- Joined: Sun Oct 24, 2004 6:21 pm

- Location: Rapid City, South Dakota

Jack, Check out my journals. That's exactly how I build. I make the sandwich wall, at the same time creating a "ledge" for the headliner to rest on. The roof spars go on top of the headliner, glued/screwed in place. I also built all of the cabinets and bulkheads in place, as well as, varnish, before adding that headliner.

Mikes Lil'Diner

Cabinets in place.

Close-up of that ledge.

Mikes Lil'Diner

Cabinets in place.

Close-up of that ledge.

Last edited by Steve Frederick on Mon Jun 10, 2013 8:16 pm, edited 1 time in total.

Blessings, Steve

Adirondacks, Upstate New York

Building Journals

The Shop Manual's 8-years old!! Thank's everyone!

New! 'Rondack Lodge Plans!Order Here!

Adirondacks, Upstate New York

Building Journals

The Shop Manual's 8-years old!! Thank's everyone!

New! 'Rondack Lodge Plans!Order Here!

-

Steve Frederick - Custom Teardrop Builder

- Posts: 1984

- Images: 29

- Joined: Thu Apr 15, 2004 5:02 pm

- Location: Upstate New York, Adirondacks (Great Sacandaga Lake)

). I skinned my walls first and the roofbows were a piece of cake to install.

). I skinned my walls first and the roofbows were a piece of cake to install.

. You trust that glue to hold the second skin onto the first?

. You trust that glue to hold the second skin onto the first?