Door Design Ideas...

12 posts

• Page 1 of 1

Door Design Ideas...

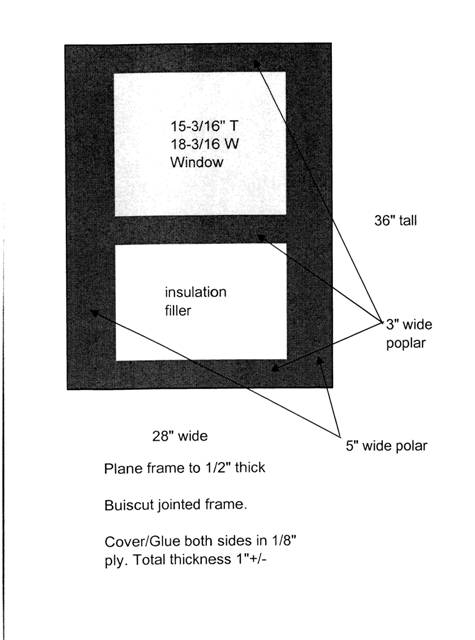

I'm at the stage to build doors...to prevent warping/twisting I can either spend $80+ on VERY good cabinet grade 3/4" ply or spend $60 on solid lumber...so here is my design idea - poplar w/ 1/8" ply on both sides; seal the entire thing w/ epoxy and paint the entire thing w/ my Brightside - no aluminum trim as there will be an interior seal using aluminum z channel for the door jam; ss piano hinge and Grants windows and lock set. Comments?

************

Keith

"Work and work and do your best! Paint and putty will do the rest!"

Keith

"Work and work and do your best! Paint and putty will do the rest!"

-

Keith B - Silver Donating Member

- Posts: 550

- Images: 148

- Joined: Mon Jan 29, 2007 3:54 pm

- Location: Wichita, KS

Let me know how it works. I do mine next week sometime. I figure with the weather we both are having if it is gonna do something strange it will do is soon.

Let me know how it works. I do mine next week sometime. I figure with the weather we both are having if it is gonna do something strange it will do is soon.

“Forgiveness means giving up all hope for a better past.â€

-

Miriam C. - our Aunti M

- Posts: 19675

- Images: 148

- Joined: Wed Feb 15, 2006 3:14 pm

- Location: Southwest MO